230

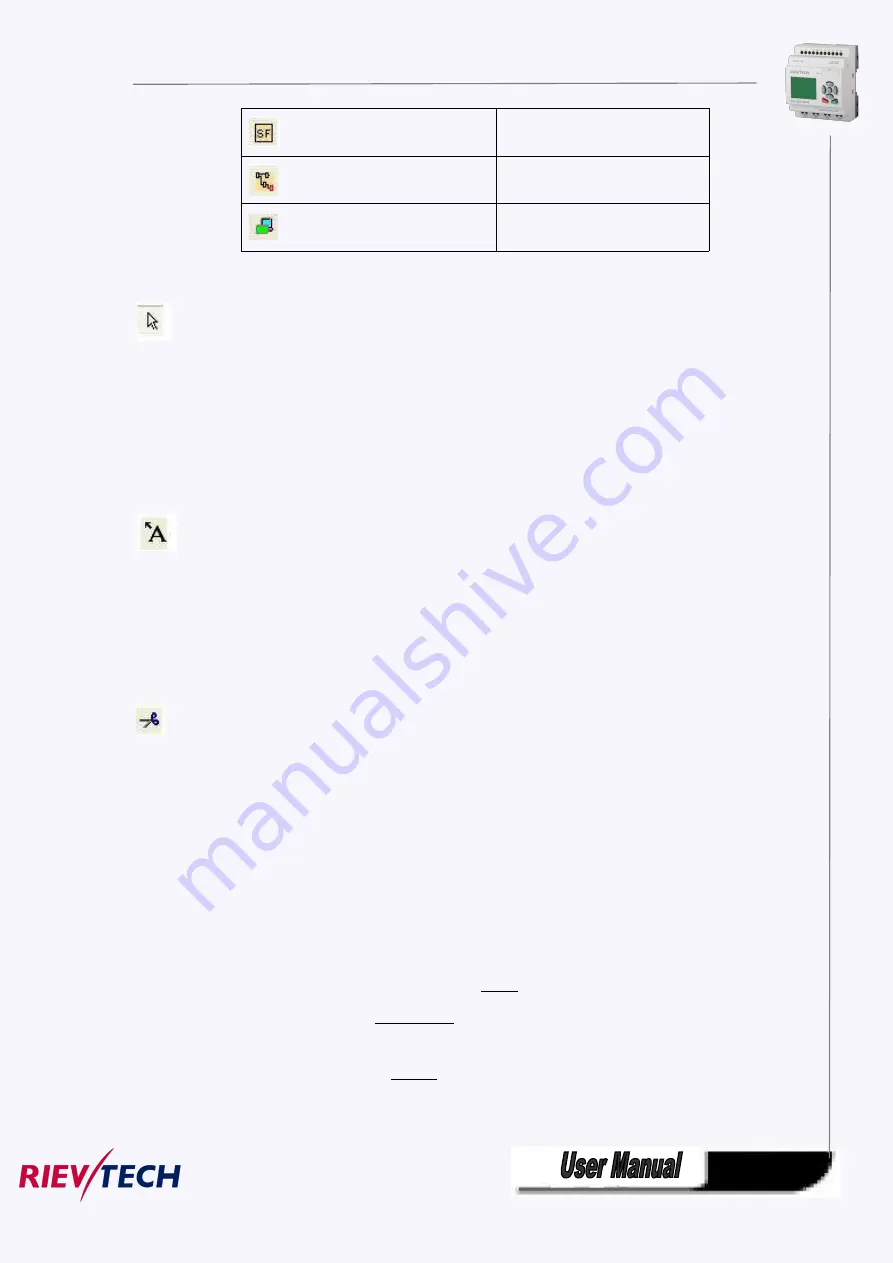

Special functions

Simulation

On-line test

Selection Tool

You can use the selection tool to select and move blocks, text and connecting lines. You can select objects

individually with a left-click; you can select multiple objects with [Ctrl]+Click, or you can use the mouse

as a "lasso" to surround objects with a rectangle and capture them as a selection.

You can call the selection tool in any other tool by pressing the [ESC] key or by clicking on the icon in the

programming toolbar.

Text Tool

This tool is used to insert or edit user-defined text objects in the programming interface. You can specify

the font type, font size and font color for each individual label.

Text figures can be set in Wrap Text format. You can adjust the size of a text figure typically by dragging

the rectangle handles.

Cut/Join

This tool is used to cut and join connections between blocks. To cut a connection, left-click to select the

relevant line while the Cut/Join tool is active. The connection is replaced at the blocks by a reference to

the partner block. The reference is labeled with the page number, block number and the I/O of the

partner block.

5.8.4 Simulation Tool and status window

A toolbox pops up when you open the simulation mode. It contains:

Icons (e.g. switches) for operator control of the inputs .

An icon for the simulation of a power failure, for testing the switching response with reference

to retentivity characteristics after power failure.

Icons (e.g. bulbs) for monitoring outputs .

Simulation control icons and

Time control icons.

Summary of Contents for ELC-12AC-R-N

Page 1: ...Applied to ELC PR series Ver 3 0 Programmable Relay User s Manual Rievtech Electronic Co Ltd...

Page 27: ...27 PR 14 and PR 18 series 1 PR 18 CPU 2 PR E extension PR 24 series...

Page 31: ...31 AC type digital inputs Analog Inputs DC 0 10V Analog inputs current Inputs 0 20mA...

Page 40: ...40...

Page 120: ...120 C Analog input value of CPU and extensions D Analog output value of CPU and extensions...

Page 121: ...121 E F digital flag status F AF analog flag value...

Page 122: ...122 G M status H AM value...

Page 221: ...221 7 Click Install button to install Program is being installed...

Page 250: ...250...

Page 256: ...256 You can read the parameters from the PLC...

Page 258: ...258...

Page 267: ...267 TCP Sever 192 168 0 227 port 8004 is ok TCP Sever 192 168 0 227 port 8005 is ok...

Page 268: ...268 TCP Sever 192 168 0 227 port 8006 is ok TCP Sever 192 168 0 227 port 8007 is ok...

Page 269: ...269 TCP Sever 192 168 0 227 port 8008 is ok TCP Sever 192 168 0 227 port 8009 is ok...

Page 290: ...290 Slave1 IP 192 168 0 101 TCP server port 8001 Slave2 IP 192 168 0 102 TCP server port 8002...

Page 317: ...317 Network settings You can view the network parameters in such table...

Page 331: ...331 B005 Read the I1 IA status from the slave1 to the F11 F20 of the master Setting as follows...

Page 332: ...332 B006 Read the I1 IA status from the slave2 to the F21 F30 of the master Setting as follows...

Page 346: ...346 7 4 2 The scheme of xLogic The circuit diagram of industry gate...

Page 353: ...353 7 6 2 The scheme of xLogic Components K1 main contactor...

Page 357: ...357 4 cursors Cursor key Type 1x MODBUS code 02 C1 C4 256 259 BIT R...

Page 392: ...392...