20154169

30

GB

Maintenance

Fan

Check to make sure that no dust has accumulated inside the fan or

on its blades, as this condition will cause a reduction in the air flow

rate and provoke polluting combustion.

Burner

Check that the graduated sector that controls the air damper is se-

cured by the nut 2)(Fig. 31, page 27).

The tightness of the screws that fasten the cables to the burner ter-

minal strip must also be checked.

Clean the outside of the burner.

Clean and grease the cam variable profile.

Boiler

Clean the boiler as indicated in its accompanying instructions in or-

der to maintain all the original combustion characteristics intact, es-

pecially the flue gas temperature and combustion chamber

pressure.

Gas leaks

Make sure that there are no gas leaks on the pipework between the

gas meter and the burner.

Gas filter

Change the gas filter when it is dirty.

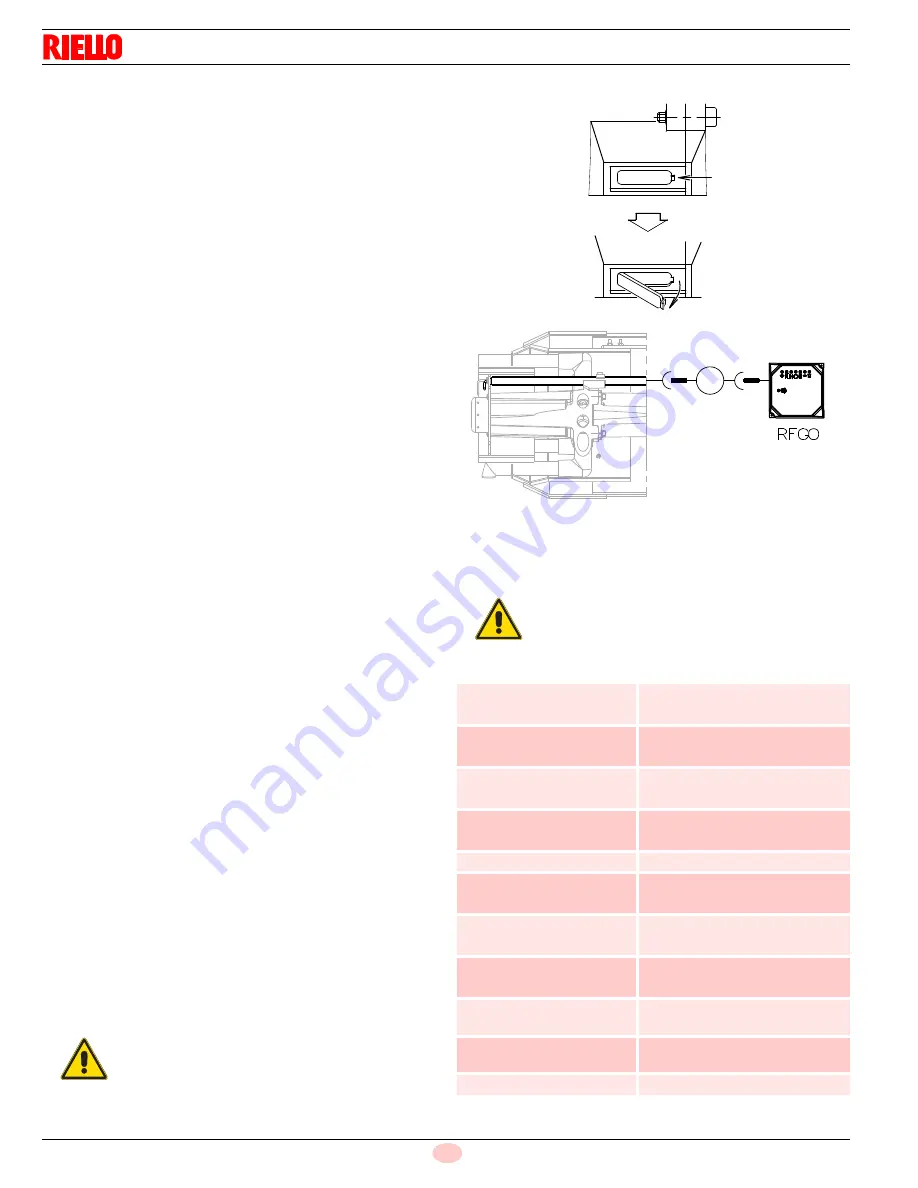

Flame inspection window

Clean the flame inspection window (Fig. 34).

6.2.4

Flame presence check

The burner is fitted with an ionisation system which ensures that a

flame is present. The minimum current for plant operation is 3

μ

A.

The burner provides a much higher current, so that controls are not

normally required.

However, if it is necessary to measure the ionisation current, there

are two methods:

Flame presence check with RFGO function

–

Check the level of the flame detection signal with the “Check

mode” function from the flame control: the LEDs from 2 to 6 in-

dicate the flame signal level, respectively. See “LED indicator

and special function” on page 32.

Check Mode

With burner flame on:

–

hold the reset button on the flame control pressed for at least

3 sec.;

–

the button colour will change from green to yellow;

–

each operating status signalling LED will be compared to 20%

of the maximum brightness;

–

press the reset button again (<0.5 sec) to reset the standard

operation of the signalling LEDs.Safety components.

Flame presence check with microamperometer instru-

ment

–

disconnect the plug-socket 7)(Fig. 4, page 10) on the ionisation

probe cable and insert a direct current microamperometer with

a base scale of 100

μ

A.

6.2.5

Safety components

The safety components should be replaced at the end of their life

cycle indicated in the following table.

Tab. M

WARNING

Carefully check polarities!

WARNING

The specified life cycles do not refer to the warranty

terms indicated in the delivery or payment condi-

tions.

Safety component

Life cycle

Flame control

10 years or 250,000

operation cycles

Flame sensor

10 years or 250,000

operation cycles

Gas valves (solenoid)

10 years or 250,000

operation cycles

Pressure switches

10 years or 250,000

operation cycles

Pressure adjuster

15 years

Servomotor

(electronic cam) (if present)

10 years or 250,000

operation cycles

Oil valve (solenoid)

(if present)

10 years or 250,000

operation cycles

Oil regulator (if present)

10 years or 250,000

operation cycles

Oil pipes/ couplings

(metallic) (if present)

10 years

Flexible hoses (if present)

5 years or 30,000

pressurised cycles

Fan impeller

10 years or 500,000 start-ups

Fig. 34

D484

-

μ A

+

20156526

Fig. 35

Summary of Contents for RS 28/M

Page 2: ...Original instructions...

Page 47: ......