20035745

24

GB

Start-up, calibration and operation of the burner

7.4

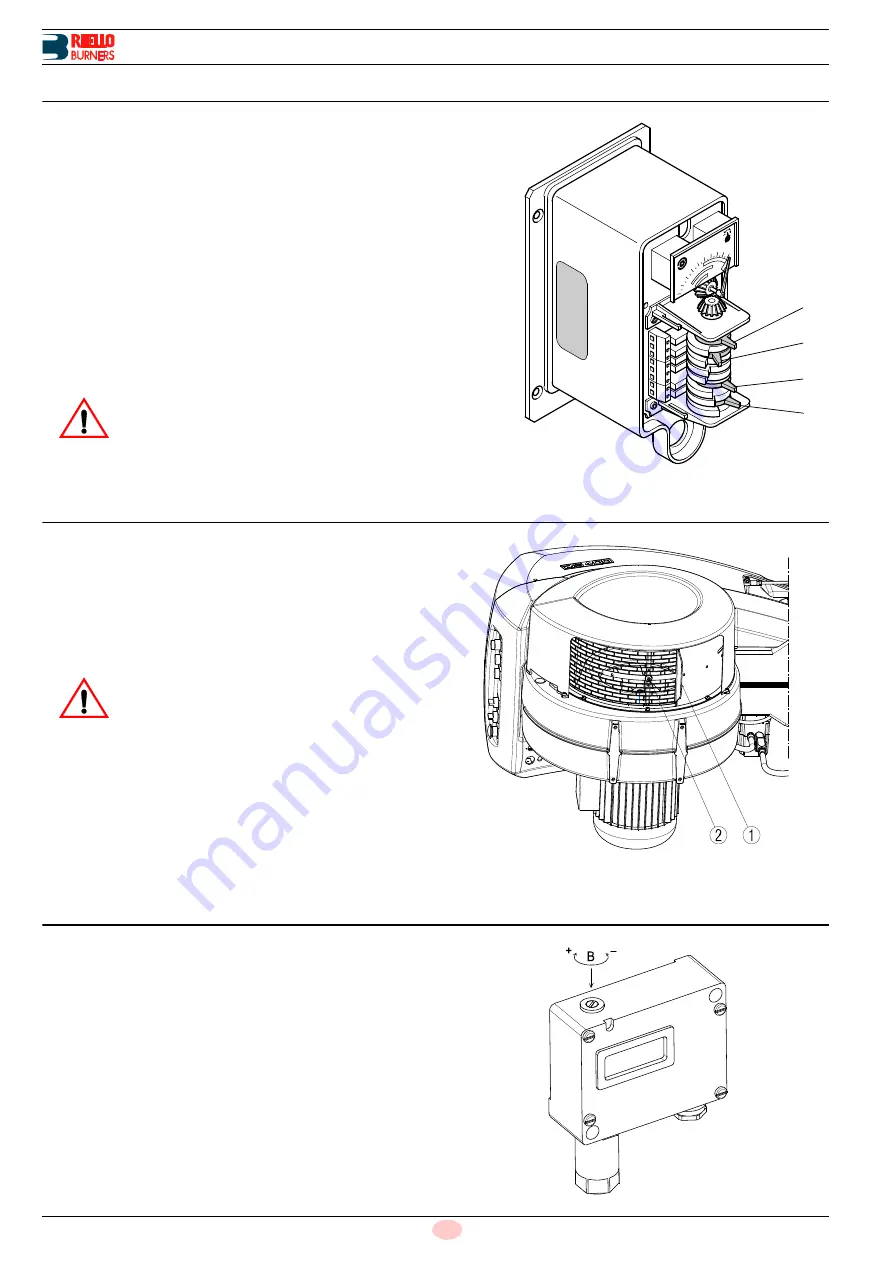

Servomotor

The servomotor (Fig. 22), by means of connection mechanisms,

simultaneously regulates air pressure and delivery and the flow

of fuel in use. It features adjustable cams that operate as many

switches.

Cam 1:

blue

limits servomotor travel to 0° position. With the burner

off, the air damper is fully closed.

Cam 2:

orange

adjusts the position of the air damper to 1

st

stage or

pre-purging (factory set to 22° position).

Cam 3:

red

adjusts air damper travel or 2

nd

stage operation with-

out exceeding 90° (factory set to 60° position).

Cam 4:

black

determines how early 2

nd

stage valve is switched on.

7.5

Air adjustment for maximum output

Set the servomotor to maximum opening (near 90°) so that the air

butterfly valves are fully open.

Loosen screw 2)(Fig. 23) under the burner’s intake and close

grille 1) progressively until you achieve the required output.

The only time reducing intake to a partial setting is not necessary

is when the burner is working at the top of the operating range

given on page 11.

7.6

Low-limit oil pressure switch

The low-limit oil pressure switch inhibits burner ignition at a pres-

sure below the pump's setting.

See Tab. F to page 17 (it comes with a factory setting of 8 bar).

If pressure is below the pump setting, the start-up cycle begins as

usual but, when the burner is to ignite, it locks out owing to the oil

pressure switch tripping.

Adjustment is made using screw B)(Fig. 24).

WARNING

Under no circumstances should the blue cam be

moved to the left, beyond the air damper closing

position.

Under no circumstances should the red cam be

moved to the right beyond 90°.

Fig. 22

4

3

2

1

D3326

WARNING

We recommend you achieve the maximum output

required manually, and adjust intake to the partial

setting and adjust the combustion head before

completing servomotor setting.

Fig. 23

D3094

Fig. 24

D3393