35

20146103

GB

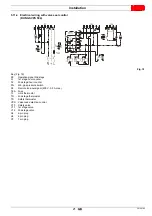

Maintenance

Fan

Check that the air damper is positioned correctly.

Check to make sure that no dust has accumulated inside the fan

or on its blades, as this condition will cause a reduction in the air

flow rate and provoke polluting combustion.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially the flue gas temperature and combustion cham-

ber pressure.

Gas train

Check that the gas train is suited to the burner capacity, the type

of gas used and the mains gas pressure.

Electrode-probe

Checking the proper positioning of the ionisation probe and elec-

trode as shown in Fig. 11 on page 15.

Pressure switches

Check that the air pressure switch and the gas pressure switch

are set correctly.

Gas leaks

Make sure that there are no gas leaks on the pipe between the

gas meter and the burner.

Gas filter

Change the gas filter when it is dirty.

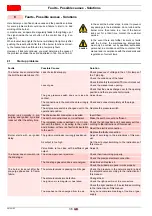

Combustion

If the combustion values measured before starting maintenance

do not comply with applicable legislation or do not indicate effi-

cient combustion, consult the Tab. O on page 33 or contact our

Technical Support Service to implement the necessary adjust-

ments.

Leave the burner working without interruption for 10 min., check-

ing the right settings at 1st and 2nd stage of all the components

stated in this manual.

Then carry out a combustion check verifying:

–

Percentage of CO

2

(%)

–

CO content (ppm)

–

NOx content (ppm)

–

Ionisation current (µA)

–

Smoke temperature at the flue

7.2.4

Safety components

The safety components must be replaced at the end of their life

cycle indicated in Tab. P. The specified life cycles do not refer to

the warranty terms indicated in the delivery or payment

conditions.

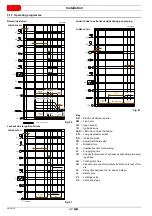

Tab. P

7.3

Opening the burner

If maintenance of the combustion head is required, refer to the in-

structions given in “Operating position” on page 14.

For accessing to the interior of the burner, loosen the screws that

secure the cover and proceed with the maintenance operation.

Check the operation

–

Start-up of the burner with a sequence of functions (see

chapter “Operating programme” on page 22)

–

Ignition device

–

Air pressure switch

–

Flame monitoring

–

Tightness test of components to the passage of fuel

Safety component

Life cycle

Flame control

10 years or 250,000

operation cycles

Flame sensor

10 years or 250,000

operation cycles

Gas valves (solenoid)

10 years or 250,000

operation cycles

Pressure switches

10 years or 250,000

operation cycles

Pressure adjuster

15 years

Servomotor (electronic

cam) (if present)

10 years or 250,000

operation cycles

Oil valve (solenoid)(if

present)

10 years or 250,000

operation cycles

Oil regulator (if present)

10 years or 250,000

operation cycles

Oil pipes/ couplings

(metallic) (if present)

10 years

Flexible hoses (if present)

5 years or 30,000 pressurised

cycles

Fan impeller

10 years or 500,000 start-ups

DANGER

Disconnect the electrical supply from the burner

by means of the main system switch.

DANGER

Turn off the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

DANGER

Operating safety hazards

Repairs to the following components may only be

carried out by the respective manufacturers or by

personnel instructed by them:

–

fan motor

–

actuator

–

air damper servomotor

–

electromagnetic valves

–

burner programmer

After carrying out maintenance, cleaning or

checking operations, reassemble the cover and

all the safety and protection devices of the burner.

Summary of Contents for 40 FS5D

Page 2: ...Translation of the original instructions...

Page 41: ......

Page 42: ......

Page 43: ......