Fr21

Pièces de rechange

Pour les pièces de rechange, appeler le 1-800-4-RIDGID

S’il vous plaît fournir l’information suivant:

-Numéro du modèle

-Numéro de série (si applicable)

-Description de la pièce et son numéro sur la liste de pièces

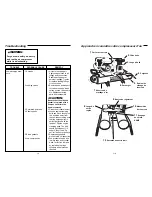

No.

No de

Numéro

Ref.

catalogue

de pièce

Description

Qté

1

17993

BG220901AJ

Montage du dispositif de protection de

la courroie

1

2

17998

ST026200AV Vis

de pression

1

3

18003

BT023100AV Courroie (4L510)

1

4

18008

ST073915AV Filtre

équipé

1

5

18013

ST073916AV

Cartouche filtrante

1

6

18018

ST070827AV Vis

4

7

18023

WL021402AV

Tube de nylon de 3/8 po

1

8

17868

ST119704AV

Raccord à coude

2

9

17798

V-215106AV

Soupape de sûreté ASME

1

10

17783

ST071626AV Vis

torx

4

11

18028

ST160002AV

Poignée de manche

2

12

17913

D-1403

Robinet de purge

2

13

17918

ST073612AV

Fiche

2

14

18033

AR053400CG

Réservoir d'air

1

15

17853

ST158300AV

Pied en caoutchouc

4

16

18038

ST116400AV Vis

4

17

18043

AA021800AV Tige

d’arbre de roue

1

18

18048

ST073613AV Bouchon

2

19

18053

WA005501AV

Roue pneumatique 10" (2,54 cm)

1

20

18058

CV006412AV

Commande d’obturateur

1

21

18063

ST128415AV Déchargeur

d’obturateur

1

22

17773

GA016900AV Manomètre,

gauche

1

23

17873

HF203300AV Raccord

2

24

17793

WL024501AV

Ensemble rég. (inclut 22, 23 et 25)

1

25

17878

GA016901AV Manomètre,

droite

1

26

18068

VT470000KB Pompe

1

27

18073

ST186600AV Tuyau de décharge

1

28

18078

PU015900AV Volant

1

29

18083

PU015400AV Poulie

1

30

18088

KE000900AV

Clé 3⁄16 po

1

31

18093

ST012200AV

Vis de pression à tête carrée

1

32

18098

BG208800AJ

Assemblage d’ancre

1

33

18103

NG002502AV Moteur

1

34

18108

ST070625AV

Vis à tête hexagonale

4

35

18113

ST011200AV Rondelle

8

36

18118

AL014000AV Contre-écrou

4

37

18123

ST164100AV

Dispositif de retenue des fils

1

10. Keep fingers away from a running

compressor; fast moving and hot

parts will cause injury and/or burns.

11. If the equipment should start to

vibrate abnormally, STOP the

engine/motor and check immediately

for the cause. Vibration is generally a

warning of trouble.

12. Check fuel level before starting the

engine. Do not fill the gas tank

indoors. Wipe off any spilled gas

before starting the engine.

13. To reduce fire hazard, keep

engine/motor exterior free of oil, sol-

vent, or excessive grease.

14. Do not tamper with governor setting

on engine. Overspeeding the unit

severely shortens engine life and may

also be very hazardous.

15. Tanks rust from moisture build-up,

which weakens the tank. Make sure to

drain tank daily and inspect periodical-

ly for unsafe conditions such as rust

formation and corrosion.

4

Safety Instructions (continued)

NEVER refuel a run-

ning or hot engine.

Explosive fuel can cause fires

and severe burns. Avoid over-

filling fuel tank.

!

WARNING:

Gasoline vapor is highly flam-

mable. Refill outdoors or only in

well ventilated areas. Do not

store, spill or use gasoline near

an open flame or heat devices

such as a stove, furnace, or

water heater, which utilize a

pilot light, or any device that

can create a spark. If gasoline

is accidentally spilled, move

unit away from the spill area

and avoid creating any source

of ignition until gasoline vapors

have dissipated.

!

DANGER:

Motors, electrical

equipment and con-

trols can cause electrical arcs

that will ignite a flammable gas

or vapor. Never operate or

!

WARNING:

Carbon monoxide can

cause severe nausea,

fainting or death. Do

not operate unit

inside a closed building or a

poorly ventilated area.

!

WARNING:

repair in or near a flammable

gas or vapor. Never store flam-

mable liquids or gases in the

vicinity of the compressor.

Never remove or attempt to

adjust safety valve. Keep safety

valve free from paint and other

accumulations.

!

WARNING:

Never attempt to

repair or modify a

tank! Welding, drilling

or any other modification will

weaken the tank resulting in

damage from rupture or explo-

sion. Always replace worn or

damaged tanks.

!

DANGER: