ENG

Page 6

233-Truck-20K-ISM-RevB-07-06-18

Troubleshooting – Air System Installation

Problem

Possible Cause

Solution

Air springs fill

but do not exhaust.

— Obstructed air line.

— Faulty controls wiring.

— Manual override pushed in

— Check for pinched/blocked lines.

— Check wiring with voltmeter and

correct wiring/installation.

— Release manual override.

Air system leaks

down after a short

period of time.

— Leak in air system beyond

accepted standards.

— Pressurize system and spray soap

water solution onto the tubing,

valves and fittings. Check for

bubbles (leaks). Note: Some valves

will leak at an acceptable rate.

— Check that tubing cuts are straight

and smooth. Re-cut and reassemble

fitting joints, if necessary.

Auxiliary unit will not

stay up

— Loose Air Fittings.

— Damaged Air Lines.

— Air lines to lift and load air

springs are reversed.

— Damaged or Worn

Air Springs.

— Check and retighten fittings. Repair

or replace component, as necessary.

— Check installation. Air line from

regulator goes to (load) air springs.

— Replace if worn or damaged.

Auxiliary unit not getting

the correct lift

— Air lines to lift and load air

springs are reversed.

— Lift air springs do not have

proper air pressure.

— Interference with driveline or

other chassis components.

— Air control system not

installed correctly.

— Check installation. Air line from

regulator goes to (load) air springs.

— Check for loose fittings or worn/

damaged lines. Verify air tank

pressure with gauge.

— Visually inspect unit operation for

proper clearance. Check for loose

fasteners and retighten.

— Check installation; refer to OEM

installation procedures.

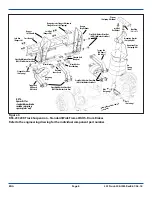

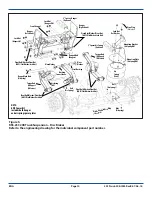

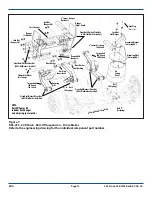

Install air system components

Connect the load and lift air springs and an air con-

trol kit to the air system (Figure 2).

The air control kit (ACK) consists of a pressure

regulator with a gauge connected to an air valve

controlled by an electric switch or manual knob. The

ACK allows the operator to control the air spring

pressure so that the auxiliary axle can support differ

-

ent loads.

Ridewell has a number of manual/electric ACK

configurations available. Installation will vary by the

type of configuration.

The installer is responsible for making sure

that air system requirements comply with the appro-

priate Federal Motor Vehicle Safety Standards.

Air Tank

Air Control Kit (ACK)

Quick Exhaust Valve

Air Springs

(Load)

Quick

Exhaust Valve

Air Springs

(Lift)

Pressure Regulator

Pressure

Protection Valve (PPV)

(Required with air brakes)

Electric Valve

Figure 2.

Example of Air Control Kit (ACK) installation