Electrical Components

SM

4-47

M154/M155/M174/M175/A0A7/M287/M0BB

Rep

lacemen

t

an

d

Ad

jus

tm

e

nt

Replacement Procedure

M287/M289

1. Pull out the standard paper tray.

2. Front cover (page 4-3 "Front Cover")

3. Rear cover (page 4-7 "Rear Cover")

4. Right cover (page 4-8 "Right Cover")

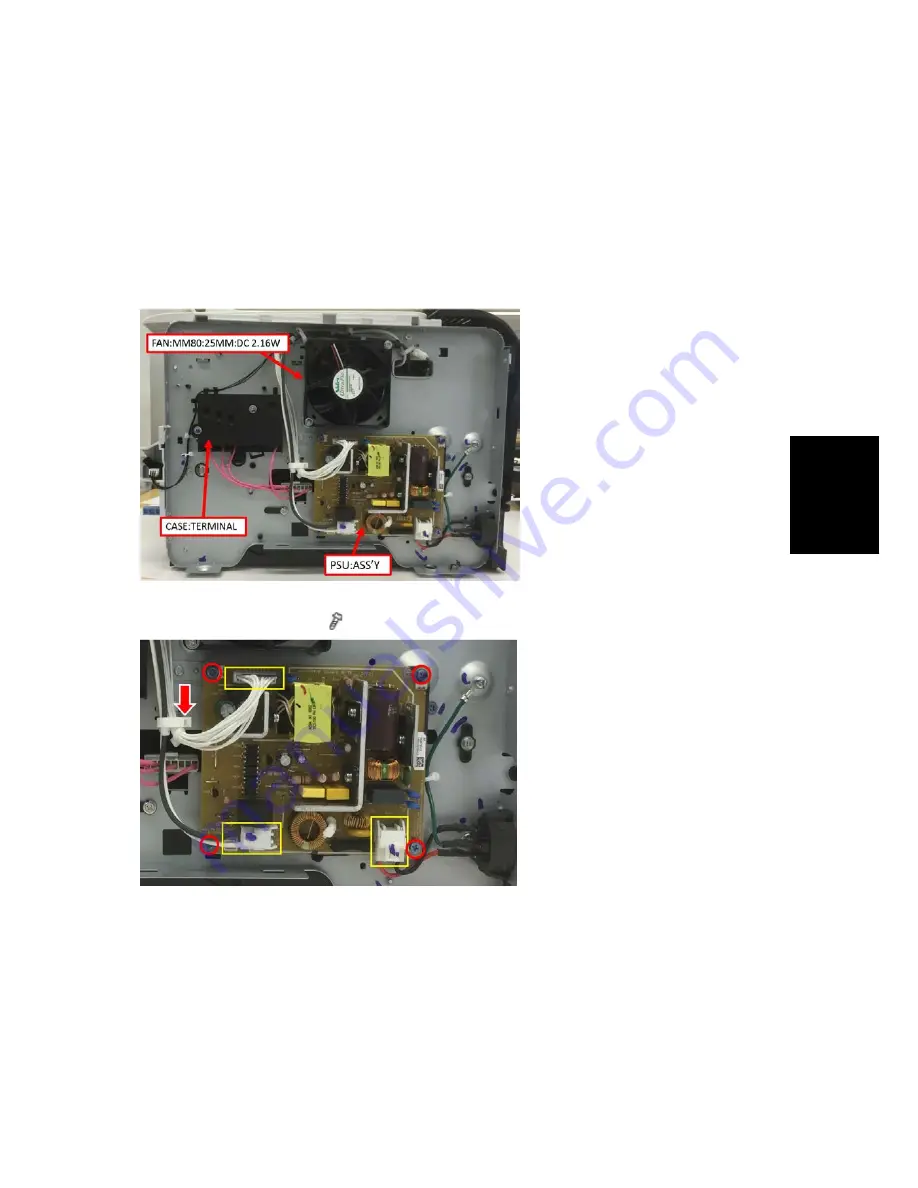

[Right side after taking the Right cover]

5. Remove the PSU:ASS’Y. ( ×4, harness x3, clamp x1)

Summary of Contents for SP 310DN

Page 1: ...M154 M155 M174 M175 A0A7 M287 M0BB SERVICE MANUAL...

Page 10: ......

Page 15: ...PRODUCT INFORMATION REVISION HISTORY Page Date Added Updated New None...

Page 16: ......

Page 20: ......

Page 21: ...INSTALLATION REVISION HISTORY Page Date Added Updated New None...

Page 22: ......

Page 26: ......

Page 27: ...PREVENTIVE MAINTENANCE REVISION HISTORY Page Date Added Updated New None...

Page 28: ......

Page 36: ......

Page 37: ...REPLACEMENT AND ADJUSTMENT REVISION HISTORY Page Date Added Updated New None...

Page 38: ......

Page 47: ...Exterior Covers SM 4 9 M154 M155 M174 M175 A0A7 M287 M0BB Replacement and Adjustment...

Page 84: ...Electrical Components M154 M155 M174 M175 A0A7 M287 M0BB 4 46 SM 20 PSU A x 4 x 1...

Page 92: ......

Page 93: ...SERVICE TABLES REVISION HISTORY Page Date Added Updated New None...

Page 94: ......

Page 136: ......

Page 137: ...TROUBLESHOOTING REVISION HISTORY Page Date Added Updated New None...

Page 138: ......

Page 159: ...ENERGY SAVE REVISION HISTORY Page Date Added Updated New None...

Page 160: ......

Page 167: ...M154 M155 M174 M175 A0A7 M287 M0BB SERVICE MANUAL APPENDICES...

Page 168: ......

Page 170: ......

Page 171: ...APPENDIX SPECIFICATIONS REVISION HISTORY Page Date Added Updated New None...

Page 172: ......

Page 178: ......

Page 180: ......