5-18

Confidential

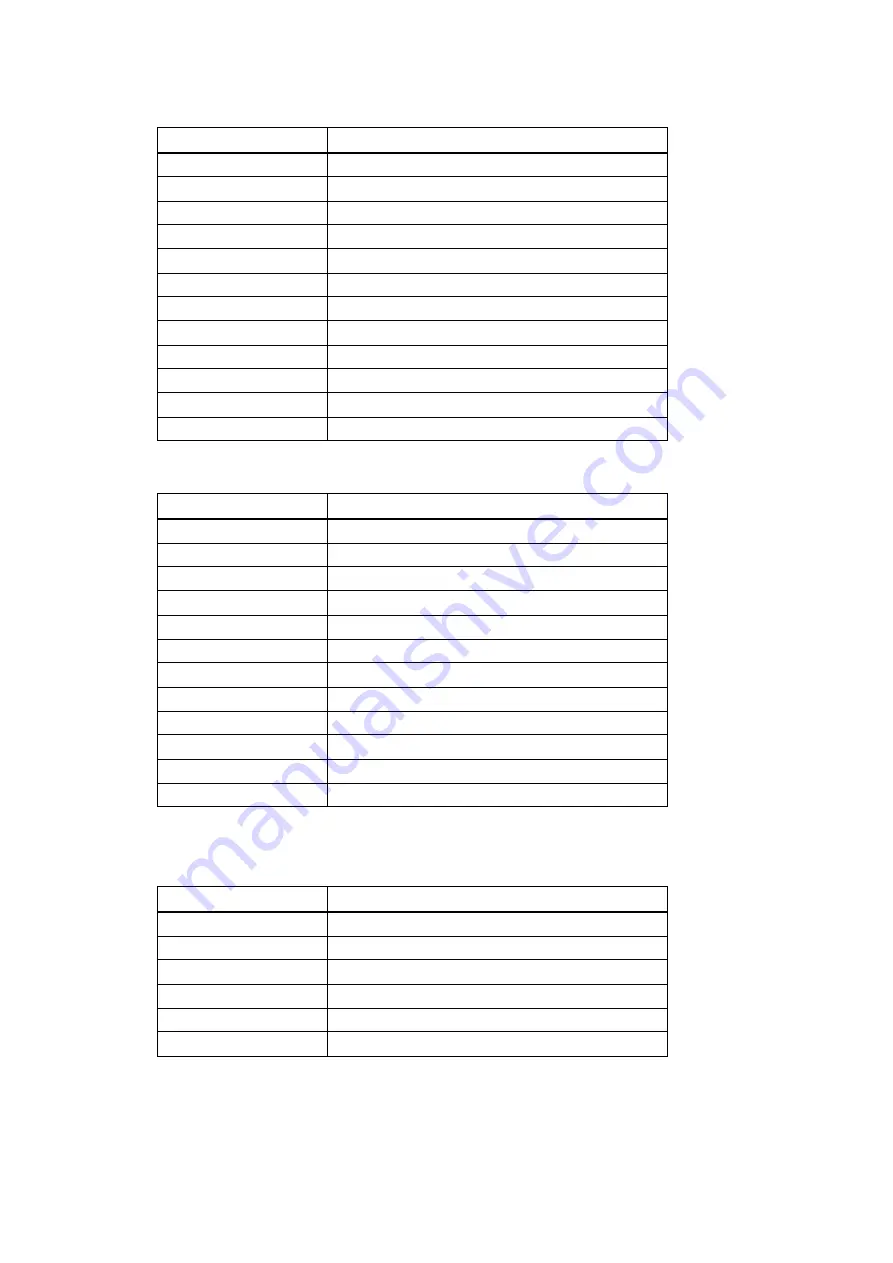

<Paper size>

<Print specification>

*

Display appears on LCD, but it is not available.

<Print type>

*

Supports paper size only for A4, Letter, Legal and Folio.

LCD

Description

SELECT:A4

A4

SELECT:LETTER

Letter

SELECT:ISOB5

ISO B5

SELECT:JISB5

JIS B5

SELECT:A5

A5

SELECT:A5L

A5L

SELECT:JISB6

JIS B6

SELECT:A6

A6

SELECT:EXECUTE

Executive size

SELECT:LEGAL

Legal size

SELECT:FOLIO

Folio size

SELECT:HAGAKI

Postcard size

LCD

Description

SELECT:PLAIN Plain

paper

SELECT:THIN

Plain paper (thin)

SELECT:THICK

Plain paper (thick)

SELECT:THICKER

Plain paper (thicker)

SELECT:RECYCLED

Recycled paper

SELECT:BOND

Bond paper

SELECT:LABEL

Label

SELECT:ENVELOPE

Envelope

SELECT:ENVTHIN

Envelope (thin)

SELECT:ENVTHICK

Envelope (thick)

SELECT:GLOSSY

Glossy paper

SELECT:HAGAKI

Postcard *

LCD

Description

SELECT: TRAY1 SX

Single-side printing from paper tray

SELECT: MF SX

Single-side printing from manual feed slot

SELECT: TRAY1 DX *

Duplex printing from paper tray

SELECT: MF DX *

Duplex printing from manual feed slot

SELECT: AUTO SX

Single-side printing to automatically selected tray

SELECT: AUTO DX *

Double-side printing to automatically selected tray