0

CIP Training

L5160/L513

Maintenance

CIP Training

C7200 series

Adjustment Settings for Operators

•

When removing jammed media or performing maintenance on the machine, avoid getting ink,

flushing liquid, and displacement liquid on your clothing. If ink, flushing liquid, and displacement

liquid come into contact with your clothing, wash the stained area with water.

•

When removing jammed media, replacing media, or performing maintenance on the

machine, avoid getting ink, flushing liquid, and displacement liquid on your skin. If ink,

flushing liquid, and displacement liquid come into contact with your skin, wash the

affected area thoroughly with soap and water.

•

The supplied gloves are consumables. If they are damaged or lost, use polythene

gloves instead.

•

When 10 minutes or more have passed after the carriage moves, the machine

will make a buzzer sound. As nozzle dryness may cause a nozzle defect,

perform nozzle maintenance promptly.

•

For cleaning liquid, use only the manufacturer-recommended cleaning liquid

bottle. For details, see "List of Consumables".

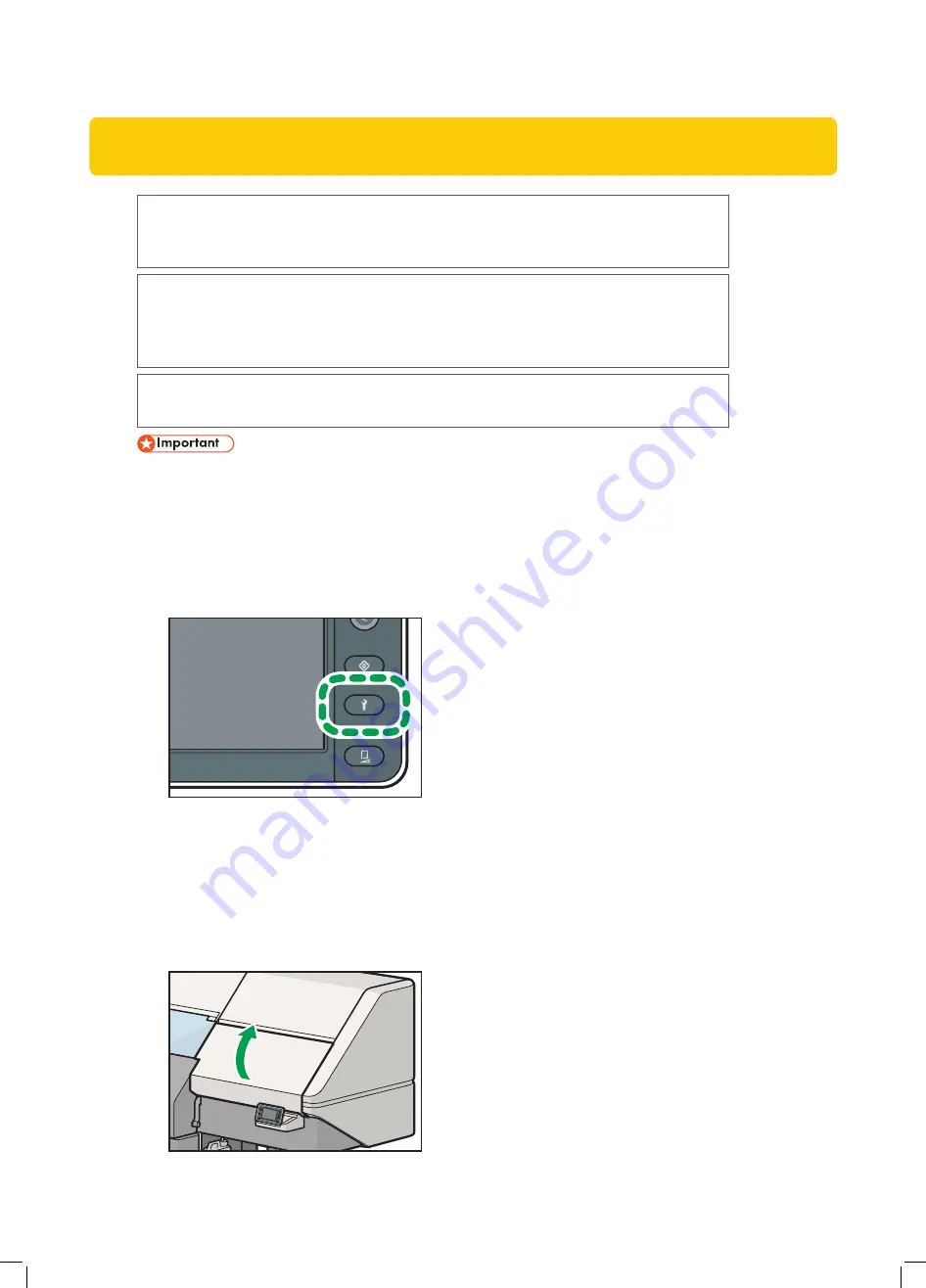

1. Press the [Maintenance] key.

DWU102

2. Press [Head Cleaning Maintenance].

3. Press [Wiping Position].

4. Press [Execute].

The carriage moves to the left side edge position and a completion of movement message is

displayed.

5. Check the message on the control panel, and then open the right cover.

DWT183