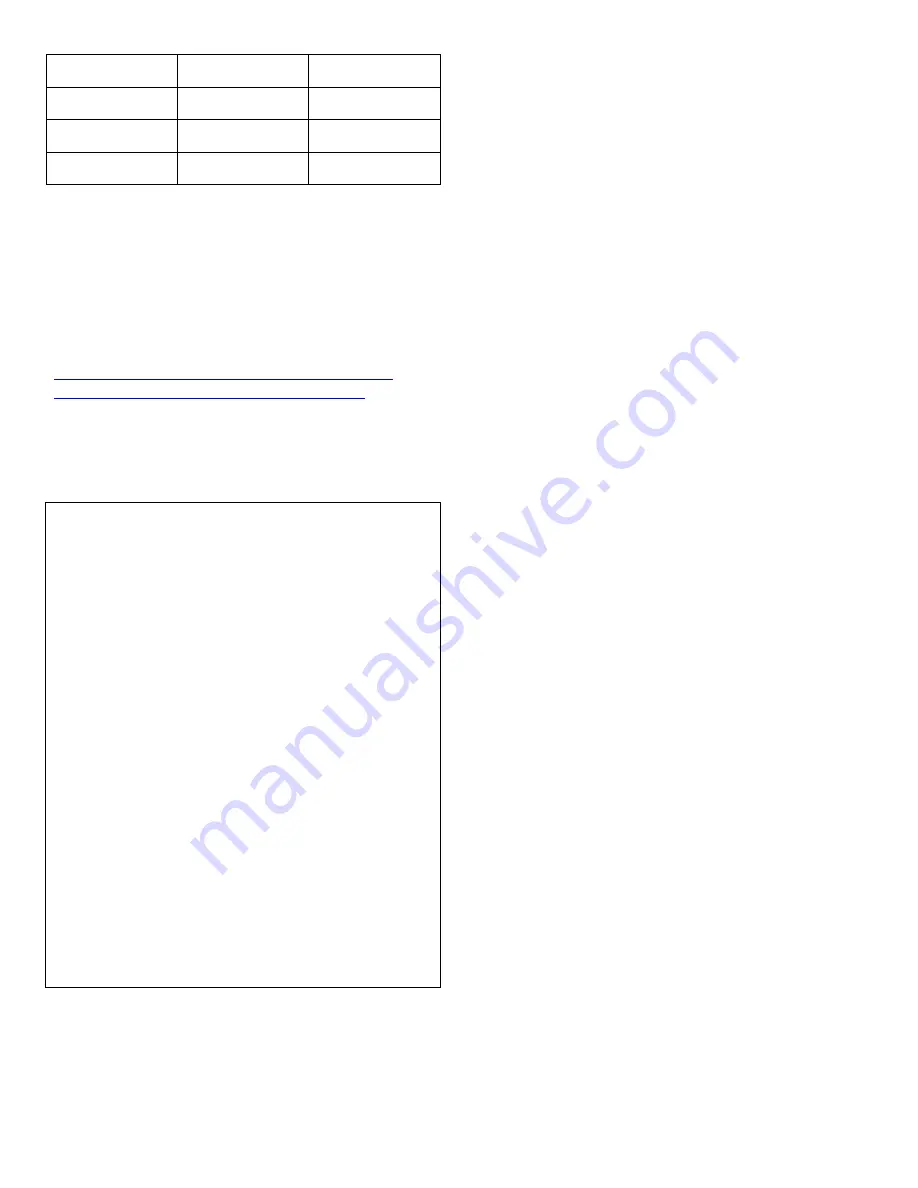

Stepped Black

Cylindrical Orange

4

Cylindrical Black

Cylindrical Black

3

Cylindrical Black

Cylindrical Orange

2

Cylindrical Orange

Cylindrical Orange

1

This pedal set has the ability to replicate the pedal firmness of

various styles of race cars. There are many factors that affect

the way a pedal should feel based on the type of car being

simulated. In a white paper titled

“

Brake Systems and

Upgrade Selection

”

published by Stephen Ruiz, Engineering

Manager and Carroll Smith, Consulting Engineer at StopTech

LLC, all aspects of a high performance racing brake system are

discussed. The full document is available at:

http://www.stoptech.com/technical-support/technical-

white-papers/brake-system-and-upgrade-selection

For our purposes, we are only interested in the section about

brake firmness and modulation. Here is an excerpt as it

applies to racing simulators:

BRAKE PEDAL FIRMNESS AND MODULATION

The human brain/body system modulates most effectively by force,

not by displacement. The side control sticks on current fighter aircraft

hardly move. The feel of the brake pedal should approach the firmness

and consistency of a brick. There are several factors at work here:

1) Brake hoses: Optimum pedal firmness cannot be achieved with the

stock fabric reinforced rubber flexible hoses which swell under

pressure - decreasing pedal firmness while increasing both pedal travel

and brake system reaction time. The first step in upgrading the

braking system of any vehicle is to replace the OEM flexible hoses

with. . .

2) Master cylinders and Caliper piston diameters: While it is true that

the most effective master cylinder arrangement is the twin cylinder

with adjustable bias bar that is universal in racing, replacing the OEM

master cylinder on a road going car is simply not practical. When

selecting an aftermarket system, make sure that the caliper bores are

designed for the specific application.

3) Disc run out and thickness variation: Run out in excess of six

thousandths of an inch (0.006") can be felt by the driver as can more

than 0.001" of thickness variation and any amount of material transfer

from overheated pads. Run out is caused by poor design of either

vanes or the junction between the friction surfaces and the mounting

bell, by poor machining, by thermal stress or by any combination of

the three.

4) Caliper and caliper mounting stiffness: Clamping force tries to open

the opposing sides of the calipers - resulting in a longer than optimum

pedal travel and uneven pad wear. The only solution is optimal

mechanical design and material selection - there is no effective

development fix for "soft" calipers. . .