12

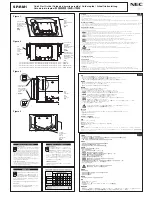

EL232 XCPD Installation Manual

3.0

Indicator Setup

This section is provided to help the installer set up indicators to the EL232 XPCD. You must determine what

indicator will supply the data to the EL232 XPCD. Once this is determined, there are certain setup parameters

which you need to know depending on which indicator is chosen.

The EL232 XPCD supports the following scale formats and are listed in Table 3-1:

•

UMC Series

•

General Freedom I and II

•

Electroscale 560

•

A & D Instruments 4322, 4323, and 4316

•

Weightronix WI-110 and WI-120

•

Toledo indicators with “high speed data format”

•

Flex-weigh DWM-4

•

Analogic AN5315, AN5316, AN5322

•

Masstron M-2500 and M-5000

•

Fairbanks 90-164 series

•

Streeter Richardson 9000

•

Cardinal 738

•

Instruments with programmable ASCII output

•

Generic smart receiver mode

3.1

Serial Data Inputs

The EL232 XPCD can accept serial ASCII data sent in RS232C, 20 mA active, or 20 mA passive current loop

formats. These formats determine the electrical way that data is transmitted. The EL232 XPCD can read the data

transmission strings sent by 12 of the more popular scale indicator families as shown in Table 3-1. It cannot read

data from indicators not included in this list unless the formatting exactly matches one on the list (or if you have

a custom program).

Note:

Set up the EL232 XPCD on the bench with the indicator you intend to use before taking it to the installation site.

Brand

Model

Interface

Baud Rate

Data Format/Notes

Condec

1000 - 2000 series

Continuous

1200 or 4800

555/600/700

1200 to 9600

General Freedom

Series I

RS232

1200 to 9600

7 data bits, parity - odd,

Series II

RS232

Electroscale

560

Current loop or RS232 in

continuous mode

1200

A & D Instruments

4322, 4321, 4316

Current loop -passive or

RS232

2400

-

Weightronix

110 and 120

Current loop or RS232

1200 to 9600

-

Toledo

-

Current loop (active or

passive)

4800

-

Flex-Weigh DWM-4

-

Current loop (active or

passive)

1200 to 9600

Data preamble - FF, FF, FF

postamble FF FF 0A

Analogic

AN5315, AN5316,

AN5322

Current loop or RS232 in

continuous mode

1200 to 9600

Table 3-1. Indicator Setup Parameters

Summary of Contents for EL232 XPCD

Page 2: ......

Page 4: ...2 ES232 XPCD Installation Manual...

Page 8: ...4 EL232 XPCD Installation Manual...

Page 28: ......

Page 29: ......