13

PROBLEMS

SOLUTIONS

POSSIBLE CAUSES

1. Air flow is low

- HRV/ERV airflow improperly

balanced

- filter clogged

- core obstructed

- exterior fresh air supply blocked

- damper is closed (if supplied)

- ductwork is restricting

- power supply low (Low Voltage)

- have professional balancer or

contractor balance the unit

- remove and clean filter

- remove and clean core

- remove and clean the blockage

- check damper

- inspect duct installation

- switch off the unit immediately and

call the electrician to check the

voltage

Maintenance (

cont’d

)

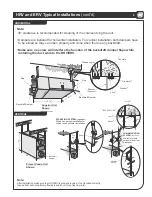

Repeat steps 1 to 5 from the previous section and continue with the following steps:

1. Clean the HRV and ERV core:

- Remove filters

- Loosen the core locking bracket

- Remove the core, carefully grip ends of core and pull

evenly outward

-

HRV Core

> remove dust using vacuum cleaner or

rinse with cold water

> Soak and rinse the HRV core in warm

soapy water

-

ERV Core

> remove dust using vacuum cleaner

2. Motors

-

Maintenance Free, permanently lubricated

3. Drain Tube and Drain Pipe -

Inspect drain tube, drain pipe and “P” trap for blockage, mold or kinks. Flush with

warm soapy water and replace if worn, bent or unable to clean.

4. Clean Duct Work if Required -

Wipe and vacuum the duct once every year. The duct work running to and from

HRV/ERV may accumulate dirt. You may wish to contact a heating / ventilation

company to do this.

ATTENTION

!

!

• Do not use cleaning solution for the HRV/ERV core

• Do not use pressure washer on the HRV/ERV core

• Do not place the HRV/ERV core in dishwasher

• Do not use bleach or chlorine

Annual Maintenance

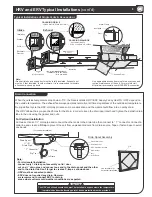

5. Cleaning the Fans -

Fans may accumulate dirt causing an imbalance and/or excessive vibration on the

HRV/ERV. A reduction in the air flow may also occur. In new construction this may result

within the first year due to heavy dust and may occur periodically after that over time

depending on the outdoor conditions.

• unplug the HRV/ERV

• open the service door

• remove the core

• disconnect the fan motor wires

• remove the screws securing fan assembly

• pull the fan assembly out of unit

• check for any accumulation on the blades

• clean with a small brush if necessary:

- scrub individual fan blades until clean

- vacuum and wipe

• put the components back in place

• reconnect the power supply and turn the unit back on.

WARNING

!

!

Electrical shock hazard. Can cause injury or death. Before attempting to perform any

service or maintenance, always disconnect the unit from its power source.

Troubleshooting

Troubleshooting

2. Senses cold air from

Supply

- Exhaust hood outside the building is

blocked

- HRV/ERV airflow improperly

balanced

- outdoor temperature is extremely

cold

- remove the blockage and clean the

hood

- have contractor balance the unit

- placement of furniture or closed

doors is restricting the movement

of air in the home

- install a duct heater

3. Water in the bottom of HRV

- drain pans, drain tube, drain pipe

and “P” trap are clogged

- check for blockage and for kinks in

line

- check connections

- make sure water drains properly