7

Reverso Pumps, Inc. www.reversopumps.com | [email protected] | Ph: (954) 522-0882

Primary Inspection, Installation, & Electrical Installation

Primary Inspection

• Upon delivery inspect the FPS (Fuel Polishing

System) for any damage that may have occurred

during shipment.

• Inspect the interior of the unit for mechanical or

electrical damage.

• If the unit is damaged upon delivery, contact the

shipping company immediately.

Mounting

• The FPS should be wall mounted on a hard, vertical

surface capable of supporting the weight of the unit.

• The control electronics are enclosed in a NEMA 4

weather proof box and will withstand being located

outside.

• In all cases the unit should be located as close as

possible to the tank being serviced. (see Max. Lift in

Technical Specifications).

• When installing the unit below the level of the fuel

on above ground fuel tanks, consideration should

be made to the installation of an anti-syphon valve

to prevent fuel spillage in the case of a leak in the

piping system.

Electrical

• Installation of unit should only be performed by

qualified installation personnel who have thoroughly

read and understands the installation instructions

covered in this manual.

• To avoid the risk of electric shock, make sure that

the power supply is disconnected. Ensure that the

power supply is at zero volts with a multimeter before

making any electrical connections.

• To ensure operator safety the FPS must be

connected to properly grounded power sources.

• Make sure that your unit and power supply are

configured for the same voltage rating.

• External control voltage must be supplied by

customer.

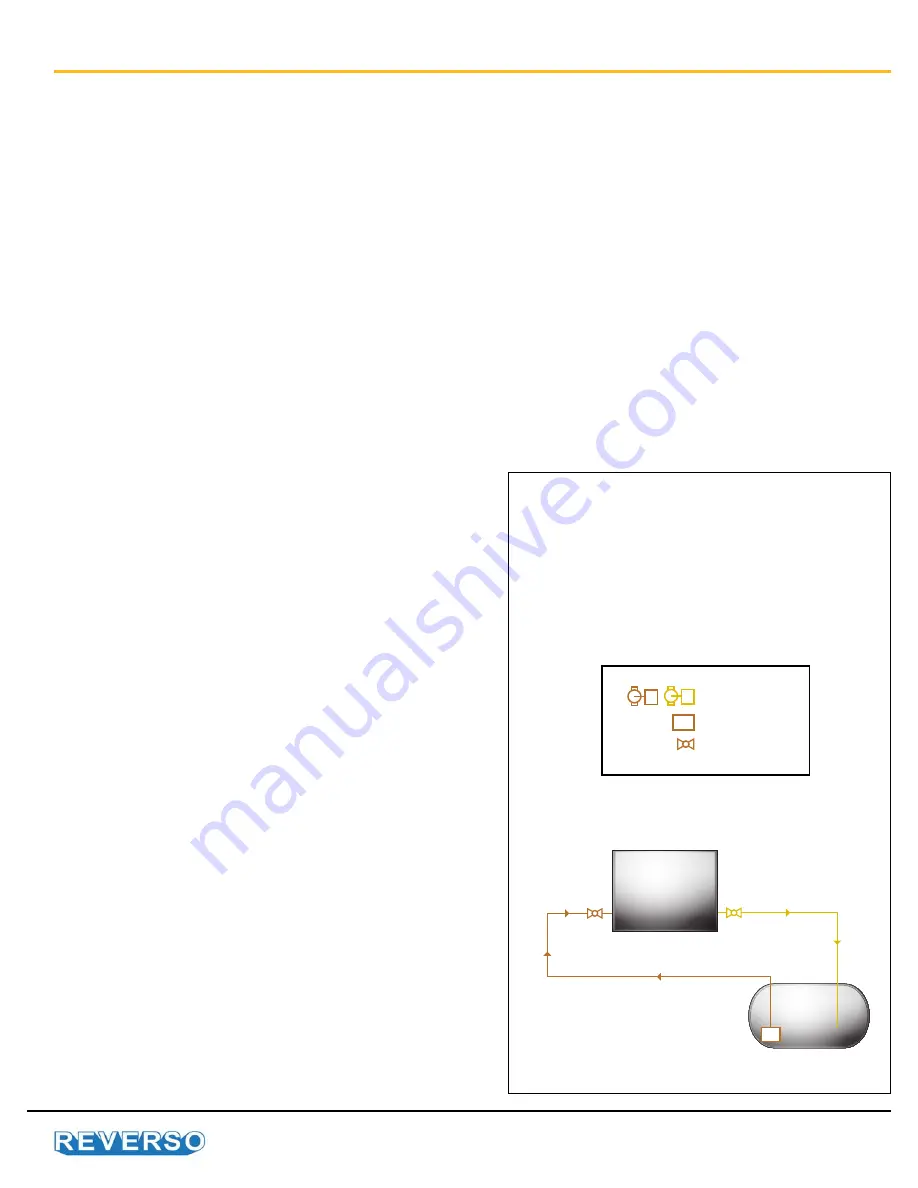

Piping

Use quality approved fuel line materials with at least

1/2” inner diameter line. Smaller plumbing will place

excessive load on the motor and shorten its life. A full

port ball valve should be installed on the inlet and outlet

ports of the FPS.

The pickup line(s) (suction) should originate from the

lowest point of the tank and should be connected directly

to the inlet. For optimal performance, ensure that this line

is free and nothing is restricting flow. It is recommended

to install a foot valve to keep the system primed,

especially if the system is located above the lowest

possible fuel level in the tank.

If the FPS is mounted below tank top level, a priming

tee should be installed on the highest point of the

suction line to be able to easily prime the systems

suction line.

The return line(s) (discharge) should be connected to

the outlet and enter the tank as far as possible from

the pick up tube and extending 2/3 down into the

tank. For optimal performance, ensure that the outlet,

discharge or return, line(s) are free and nothing is

restricting their flow.

The suction line of the FPS must be independent and

separate from the suction line of the engine. Do not

integrate into engine fuel system.

When installing this unit, FLEXIBLE CONNECTIONS

MUST BE USED TO REDUCE STRESS on the

plumbing and prevent damage to the unit.

Hoses, piping, solenoid valves and foot valves

shown in the diagrams below are not provided

with the system and must be provided by the

user/contractor, unless agreed upon otherwise.

Fuel

Tank

FV

Fuel

Polishing

System

Fuel

Tank

#

1

Fuel

Tank

#

2

Fuel

Tank

#

3

Fuel

Tank

#

4

S

S

S

S

S

S

S

S

FV

FV

FV

FV

S

S

FV

Solenoid valve

Foot valve

Ball valve