17

For reasons of operational

readiness, functional safety,

economic efficiency and compliance

with emission limits, the operator

shall have the installation inspected

by an authorised expert at least

once a year.

■

The entire unit, including

the heat exchanger, combustion

chamber and fan burner, must

be cleaned of adherent dust or

dirt

■

The combustion residues in

the combustion chamber and

in the heat exchanger are to be

removed by appropriate means

■

The V-belt tension and the

motor fastening must be

checked regularly

■

Wear parts such as flue gas

brakes, seals, oil filter insert, oil

nozzles etc. must be checked

and replaced if necessary

■

It is essential to follow the

maintenance instructions for

the separate forced-air burners.

Care and maintenance

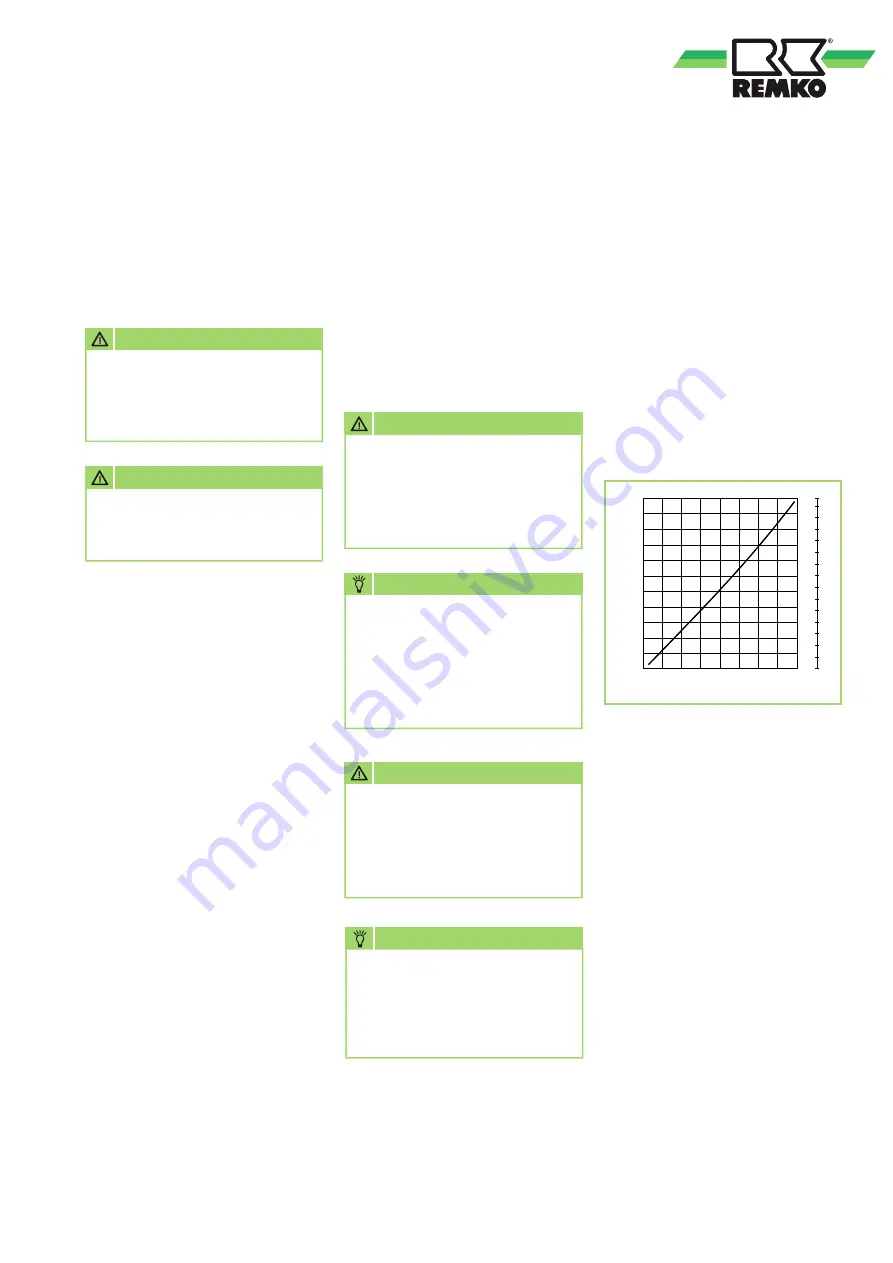

Rußschichtdicke [mm]

0

1,0

2,0

3,0

4,0

Wirkungsgradverluste

[%]

Anstieg

der

Abgastemperatur

[K]

40

0

80

120

160

200

6

0

8

10

12

14

4

2

■

The restrictions on exhaust gas

losses per §1 paragraph 1 of

the ordinance on small furnace

systems (1st. BImSchV must be

observed

■

Proof of the work carried

out by authorised specialist

personnel, together with

the usual logs, is therefore

mandatory

Soot deposits

Even small deposits of soot on

the heat transfer surfaces of

the combustion chamber and heat

exchanger will insulate the heat

output.

This results in a deterioration of

the combustion efficiency.

A soot layer just 1 mm thick can

cause an exhaust gas temperature

increase of approx. 50 K

(see diagram).

As can be seen from the above,

optimal burner adjustment

and regular maintenance are

indispensable for maintaining

efficiency and emission limits.

CAUTION

Prior to maintenance or

repair work, the unit must be

disconnected from the mains

power supply.

CAUTION

It is not sufficient to switch off

the unit only via the operating

switch!

CAUTION

Adjustment and maintenance

work on the unit and forced-

air burner may only be

carried out by authorised and

qualified technicians!

NOTE

We recommend concluding a

maintenance contract with an

authorised specialist company

for regular maintenance and

cleaning work.

CAUTION

If the operational cleaning and

burner adjustment intervals are

not adhered to, all warranty

claims will be invalidated!

NOTE

Contact the unit manufacturer

before you replace the parts

with parts or components other

than those listed in the spare

parts list.

Soot layer thickness [mm]

Efficiency losses [%]

Increase in exhaust gas temperature [K]