12

REMKO PGM (E) series

Gas burner

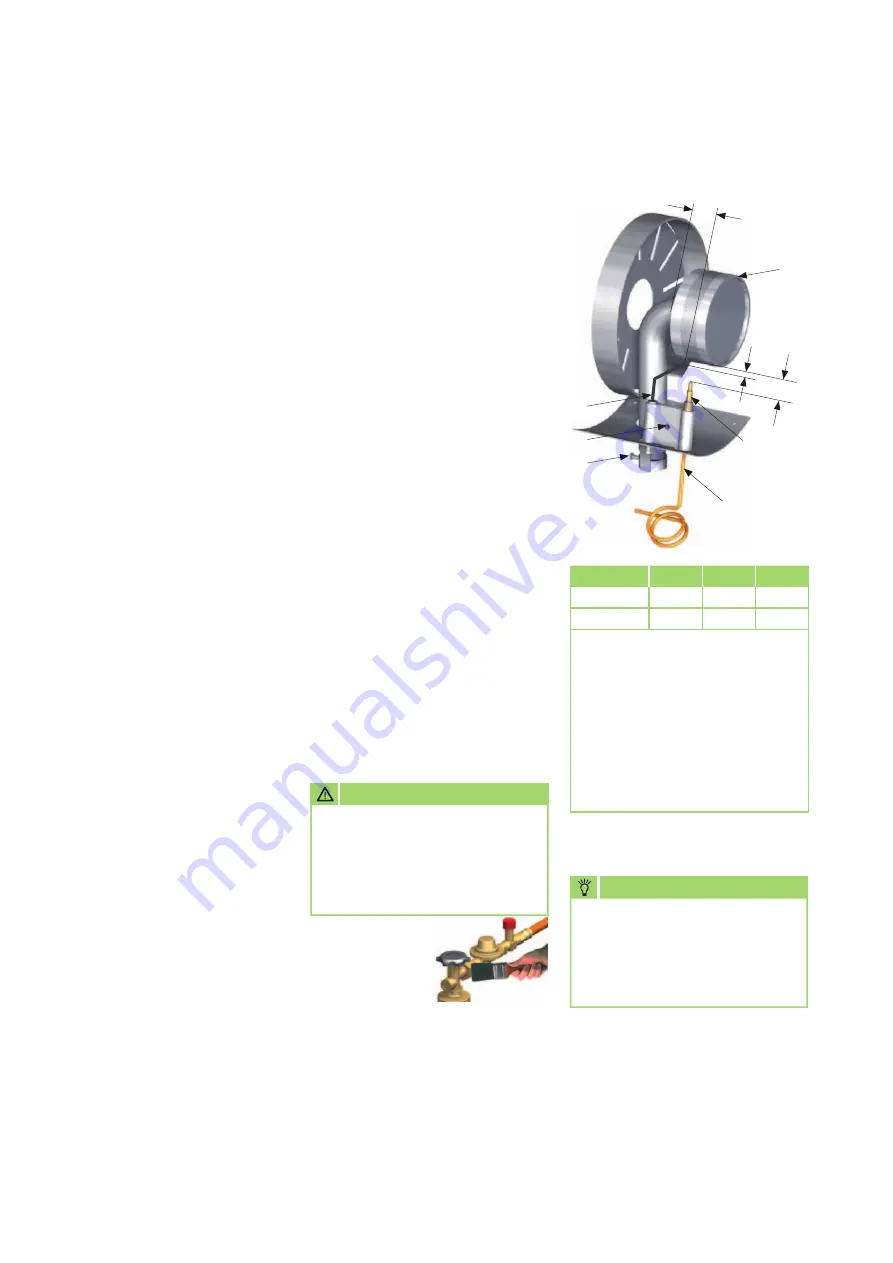

Unit type

A

B

C

PGM 30 approx. 3 approx. 15 approx. 20

PGM 60 approx. 3 approx. 15 approx. 35

All dimensions in mm

Legend:

1 = Gas burner

2 = Thermocouple

3 = Capillary tube

(fixed component of the thermocouple)

4 = Ignition electrode

5 = Clamping screw

(electrodes)

6 = Clamping screw

(gas nozzle)

Disassembling and cleaning

the gas burner

1. Switch off the gas supply

to the unit and remove the

power plug from the mains

socket.

2. Remove the protective outlet

grille, exterior cladding and

inspection cover.

3. Undo the clamping screw 6

of the nozzle holder.

4. Remove the ignition cable from

the ignition electrode 4.

5. Detach the capillary tube 3

of the thermocouple from the

safety pilot.

6. Loosen the clamping screw 5

on the electrode bracket and

carefully draw out the ignition

electrode.

7. Carefully pull the thermocouple

with capillary tube down and

out.

Be aware of the extremely

sensitive capillary tube here!

8. Carefully remove any adhered

deposits from the ignition

electrode and thermocouple.

9. Detach the fastening screws

of the gas burner and remove

the complete gas burner from

the unit.

10. Carefully clean the gas burner

with a suitable brush and

possibly compressed air.

11. Clean the gas nozzle

if necessary.

Do not use any sharp-edged

objects!

12. Carefully remove deposits

or soiling in the unit base.

13. After all cleaning work on

the gas burner, carefully refit

all parts in reverse order.

14. After using the gas nozzle,

tighten the clamping screw 6

again.

15. Adjust the ignition

electrode and thermocouple

in accordance with the sketch

and tighten the clamping

screw 5 of the electrode

bracket.

16. Carefully refit all parts

of the unit in reverse order.

1

5

2

4

6

A

B

C

3

for example with:

Soap solution or

leak detection

spray.

NOTE

A strongly yellowy flame

indicates an inadequate

fresh air supply or dirt inside

the unit.

CAUTION

A functional inspection of

the entire unit including leak

testing of all gas-conveying

connections must be

conducted