9

Shutdown

Important information about the equipment's cool-

down phase

The supply air fan runs to cool off the combustion

chamber and the heat exchanger further and does not

switch off till later.

The fan may run several times until it switches off per-

manently!

1. Switch the operating switch to the "0" position (off).

2. Shut off the fuel supply.

Never (except in emergency situations) interrupt

the mains connection before the entire cool-

down phase comes to an end.

Our guarantee does not cover damages caused

to the unit by overheating.

Cleaning

After every heating period or even earlier, depending on

the operating conditions, the equipment, including the

heat exchanger, combustion chamber, and forced-air oil

burner, must be cleaned of dust and dirt.

Parts subject to wear, such as waste gas suppressors,

seals, oil filter inserts, and oil nozzles, should be

checked and exchanged if necessary.

Maintenance and Care

The regular care and observance of some basic prereq-

uisites guarantee malfunction-free operation and a long

service life of the unit.

◊

Keep the unit free of dust and other deposits.

◊

For cleaning, use a clean, slightly moistened cloth

with which you can wipe off the dirt from the surface.

◊

Do not use a water jet.

◊

Do not use caustic cleaning agents or cleaning

agents containing solvents.

◊

Even in case of extreme soiling, only use suitable

cleaning agent.

◊

Use only clean EL heating oil or diesel as fuel.

Look for paraffin formation. Do not use biodiesel.

◊

Check the fuel filter for soiling at regular intervals.

Dirty filters must be replaced.

◊

Check the unit for mechanical damage and have de-

fective parts replaced by an expert.

◊

Check the fan blades and combustion chamber with

the heat exchanger for soiling at regular intervals

and clean them when necessary.

◊

Check on-site oil tanks for soiling and foreign bodies

regularly and clean them when necessary.

◊

Always make sure the chimney and combustion air

duct are always in perfect working order.

Before all work on the device, the mains plug must

be removed from the mains socket.

◊

Regularly check safety devices to ensure that they

are working properly.

◊

Always keep the sensors of the safety devices free

of dust and dirt.

◊

Have the exhaust emission values of the forced-air

oil burner checked regularly by authorised person-

nel.

For safety reasons, we recommend the conclusion

of a maintenance contract.

◊

Observe the maintenance and service intervals.

Adjustment and maintenance tasks may be per-

formed only by authorised expert personnel!

1. Set the operating switch to the "0" position and pull

the plug from the mains socket.

.

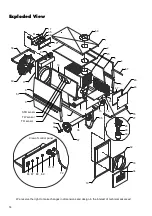

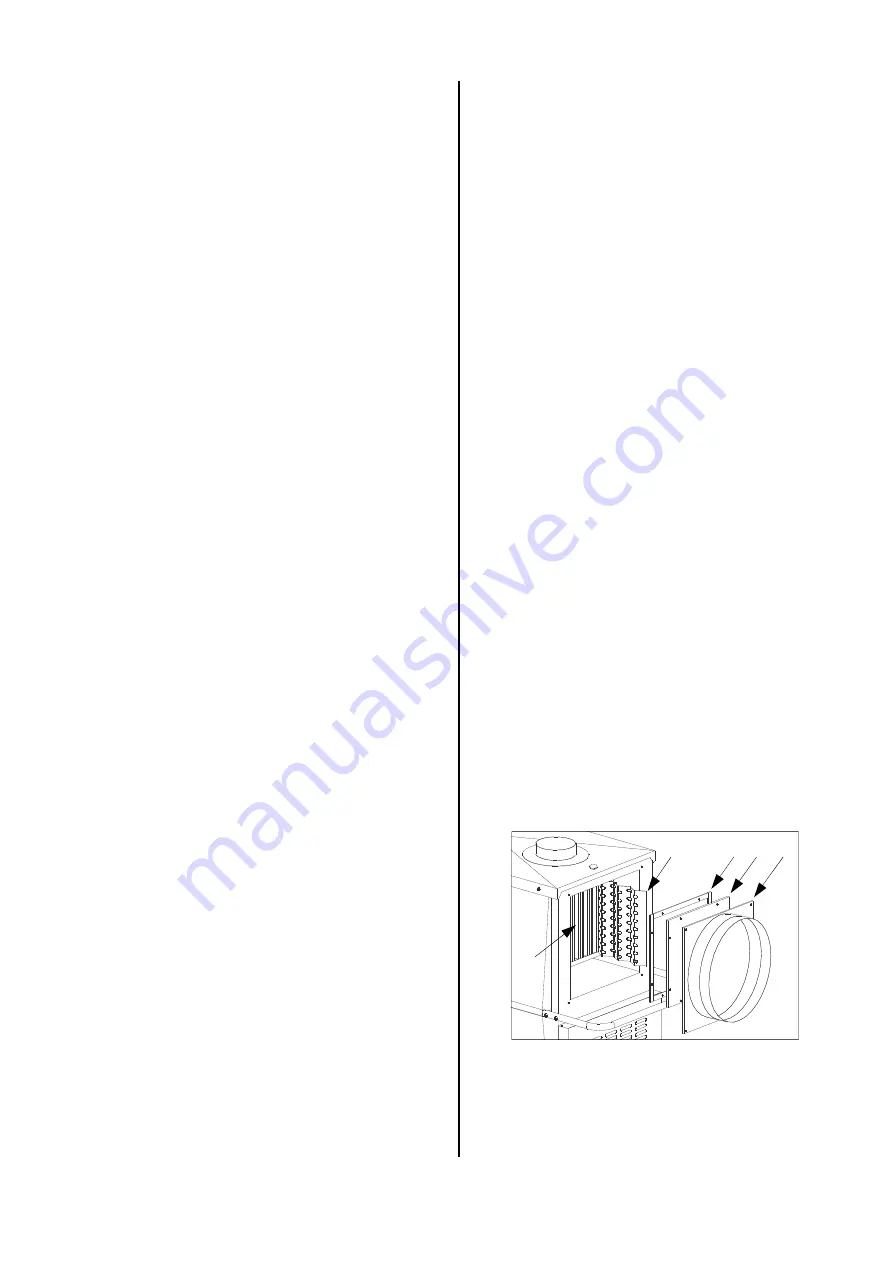

2. Remove the blow-out cone (1) after unscrewing the

four fixing screws.

Any hot air tubes or pipes must be dismantled as

well if pertinent.

3. Remove the revision cover (2) and take the waste

gas suppressor (4) out of the unit.

4. Clean all waste gas flues (5).

A special cleaning is available as an accessory un-

der EDP No. 1103110.

Cleaning the heat exchanger

5. Clean the waste gas suppressors and replace any dam-

aged ones if necessary.

6. Check the seals (3) of the revision cover and replace

any damaged seals.

7. Please observe the notices on the next page.

5

3 2

4

1

Summary of Contents for CLK 20

Page 2: ......