8

Commissioning

Someone who has been sufficiently trained in the corre-

sponding handling of the unit must be assigned with its

operation and monitoring.

Important notice before the startup of a cold unit

The preheating of the nozzle stock delays the start of

the unit dependent on temperature.

Connecting the unit to the power supply

1. Switch the operating switch to the "0" position (off).

2. Connect the mains plug of the unit only to a properly

installed and sufficiently secured mains socket.

3. Open all shut-off fittings in the oil supply.

When operating the unit for the first time, air in the oil

supply can cause the burner to shut down due to a

malfunction.

Ventilation

In this switch position, only the supply air fan runs and

the unit can be used for air circulation.

1. Turn the operating switch to the "

II

" position

(ventilation).

2. Please note: in this mode, regulation of the

thermostat and heating mode are not possible.

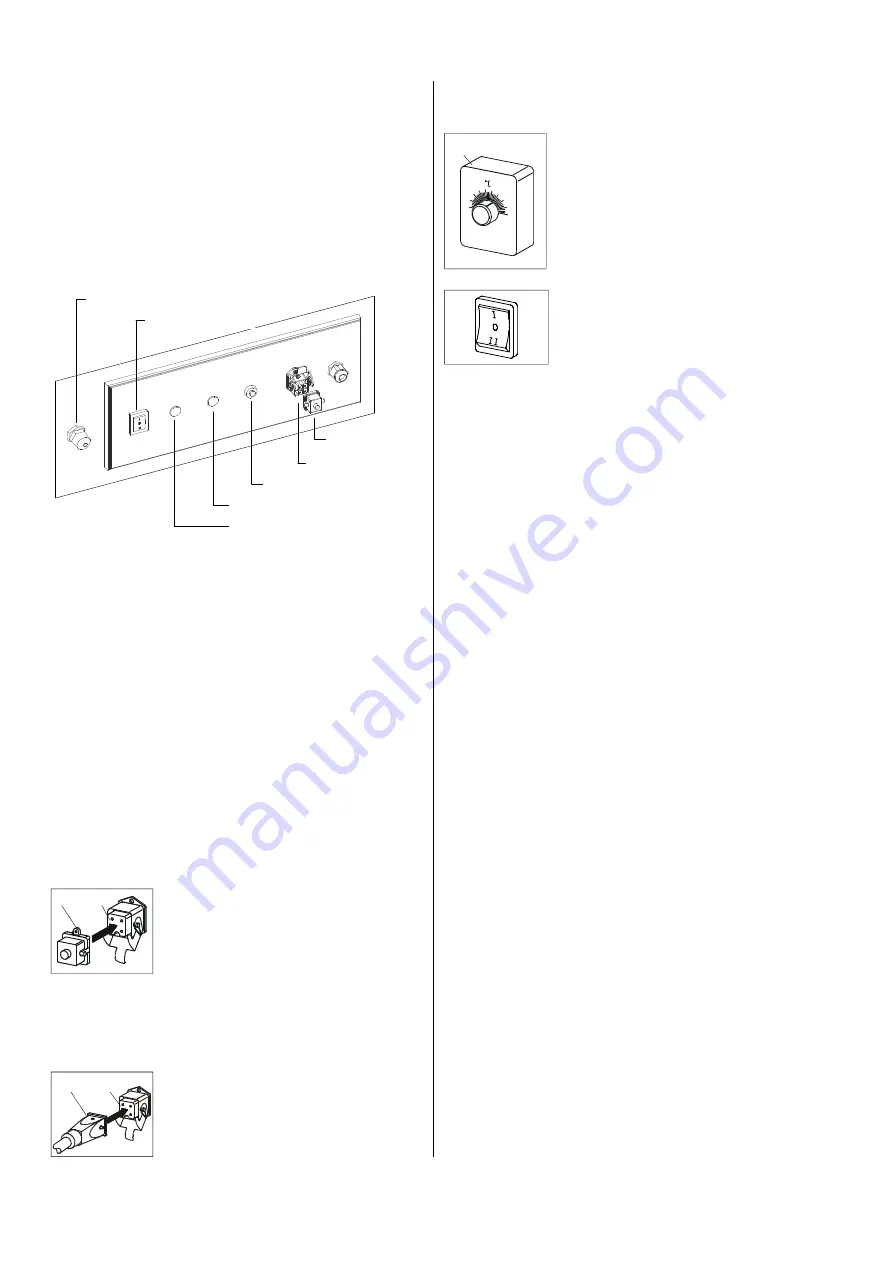

1. Connect the jumper plug (2) in-

cluded in delivery with the thermo-

stat socket (1) on the unit.

2. Switch the operating switch to the

"I" position (heating).

Heating without room thermostat

The equipment works in continuous operation.

1

2

1. Disconnect jumper plug 2.

2. Connect the plug (3) of the room ther-

mostat (4) together with the thermo-

stat socket (1) of the device.

Fully automatic heating with room thermostat

The unit operates fully automatically depending on the

room temperature.

1

3

4

Hot air distribution

The units are equipped with a high-performance axial

fan. This fan has been designed to transport the hot air

directly and effectively.

The distribution of the air should preferably take place

using the on-site outlet nozzle.

If necessary, pipes or special hot-air tubes or foil hoses

for air distribution in the possible area of fan output

(observe the channel resistance/equipment compres-

sion).

◊

Use only hot air tubes (accessories) approved by

Remko. In the process, pay attention to the air direc-

tion!

◊

To prevent heat from building up, the pipes and

tubes may not have sharp kinks and bends.

◊

Counterpressure may not be allowed to build up

when using tubes to heat enclosed spaces.

◊

If suction temperatures increase or if there is resis-

tance at the air output opening, the forced-air burner

can be switched off at short notice by the tempera-

ture monitor (TW) during heating.

When the temperature falls, the burner restarts auto-

matically.

◊

If the intervals are too short, the length of the hot air

pipes and tubes should be checked.

Avoid starting the burner in frequent cycles (run

times under five minutes).

If the temperature becomes too high, the heating

mode is interrupted permanently by the STB!

Operating switch

Control panel

Jumper plug

Thermostat socket

„Burner“ reset button

„Burner Fault“ red control lamp

„Operation“ green control

Safety temperature limiter

Note about the "Operation" control lamp

The control lamp indicates that the unit is in "Heating"

mode.

When the unit is in "Ventilation

"

mode, nothing is displayed

if the room thermostat is switched off or if the STB was ac-

tivated.

3. Place the room thermostat in a suit-

able spot.

The thermostat sensor may not be

located within the flow of hot air and

may not be directly attached to a

cold foundation.

4. Adjust the desired temperature on

the room thermostat.

5. Switch the operating switch to the

"I" position (heating).

If heat is needed, the forced-air

burner switches on automatically

and the unit functions fully automati-

cally.

Summary of Contents for CLK 20

Page 2: ......