PAGE 8

Reimers Electra Steam, Inc. 01/10/2022

HLR 120‐180 Manual ‐ English

REV 1

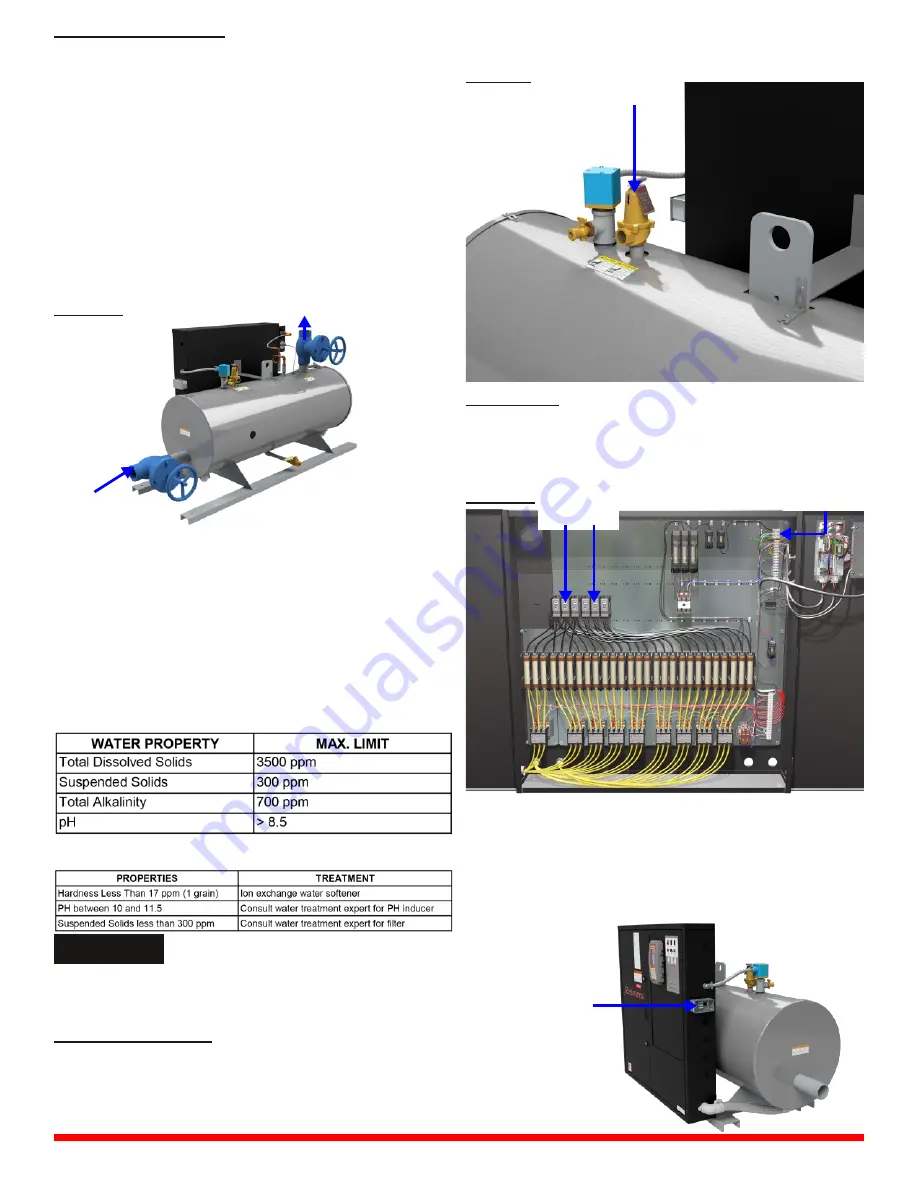

Piping: This hot water boiler is intended to be used in a

closed pressure system with a circulating hot water pump.

The boiler safety relief valve can have settings from 30 and

up to 150psig. The expansion tank must be sized to meet

the ASME standards for the overall water capacity of your

heating system. The circulating system should also include

an air trap and bleed, as well as automatic water fill. The

water inlet and outlet are located on top of the boiler as

shown in FIGURE 2.

Recommended heating loop piping size, depending on the

boiler heating power:

HLR210 – HLR300: 3" NPS

HLR330 – HLR510: 4" NPS

Install stop valves as close as possible to the boiler supply

and return ports (FIGURE 2).

In order to ensure long term troublefree boiler operation,

we recommend that the water used as boiler feed water to

be tested for hardness. If the water in your area is harder

than 1grain (17mg/L), use a water softener. The main

cause for premature heating element failure in electric

steam boilers is water hardness. If severe corrosion during

inspection of the pressure vessel as indicated in chapter

3.4 of this manual becomes evident, additional tests of

your boiler feed water must be performed. A water analysis

should be performed by a qualified and recognized water

treatment company located in your area.

Recommended levels for boiler feed water:

Recommended levels for boiler water (water inside

pressure vessel when boiler is operating)

The safety valve is designed to discharge hot steam when

the set pressure is exceeded. Ensure that the discharge

port is pointing toward the back of the unit away from the

operator and any aisles. If it is required that discharge

piping be installed from the safety valve, the pipe should

not be smaller than the valve outlet and should be rigidly

supported so as not to place weight on the valve itself.

Important: No valve in this line!

Install a fused disconnect switch near the boiler. It should

be fused as marked on the boiler name plate. Connect the

power supply from the disconnect switch to the terminals in

the boiler control panel. A copy of the wiring diagram is in

the control panel.

Important: Electrical connections to the boiler control panel

(FIG. 3) should be made by a qualified Electrician. All

wiring must comply with local electrical codes.

All boiler models that are equipped with a transformer

option (OPT1010 or OPT1011) do not require a separate

external control voltage power supply.

NOTICE

Do not add any chemicals to

the boiler feed water unless

specifically recommended by a

qualified and recognized water

treatment company.

1.2 Heating Loop Piping

1.3 Safety Relief Valve

1.4 Electrical

Safety Valve

FIGURE 2

Return Line

Supply Line

FIGURE 2

Main Power

FIGURE 3

Control

Voltage

ROOM/PROCESS

THERMOSTAT

CONNECTION