Regency CI1203 / CI1253 Wood Cast Insert

| 9

9

|

installation

CHIMNEY

SPECIFICATIONS

Before installing, check and clean your chimney

system thoroughly. If in doubt about its condition,

seek professional advice. Your Regency Insert is

designed for installation into a masonry fireplace

that is constructed in accordance with the require-

ments of "The Standard for Chimneys, Fireplaces,

Vents, and Solid Fuel Burning Appliance", N.F.P.A.

211, the National Building Code of Canada, or the

applicable local code requirements.

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical

code, CSA C22.1.

Regency Inserts are designed to use either a 5.5"

(140mm) or 6" (152mm) flue.

This insert must be connected to a code-approved

masonry chimney or listed factory-built fireplace

chimney with a direct flue connector into the first

chimney liner section.

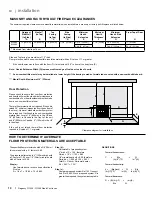

Requirements for Installing

Solid-fuel Inserts in Factory-built

Fireplaces.

1)

The insert must be tested and meet the require-

ments of UL 1482 (U.S.) and or ULC S628

(Canada) when tested in a masonry fireplace

built per ULC S628.

2)

The factory-built fireplace must be listed per

UL 127 or ULC S610.

3)

Clearances obtained from the masonry fireplace

tests are also relevant for installation in factory-

built fireplaces.

4)

Installation must include a full height listed

chimney liner type HT requirements (2100

degree F.) per UL 1777 (U.S.) or ULC S635

(Canada). The liner must be securely attached

to the insert flue collar and the chimney top.

5)

Means must be provided to prevent room air

passage to the chimney cavity of the fireplace.

This may be accomplished by sealing the

damper area around the chimney liner, or

sealing the fireplace front.

Regency Inserts are constructed with the highest

quality materials and assembled under strict quality

control procedures that ensure years of trouble free

and reliable performance.

It is important that you read this manual thoroughly

and fully understand the installation and operating

procedures. Failure to follow instructions may result

in property damage, bodily injury or even death. The

more you understand the way your Regency Insert

operates, the more enjoyment you will experience

from knowing that your unit is operating at peak

performance.

BEFORE INSTALLING

YOUR INSERT

Note:

The CI1203 does not include a blower and

one cannot be added to this appliance. If a blower

is required, you must purchase the CI1253 which

comes with a standard blower. The CI1253 has

an increased height to accommodate the blower.

1)

Read all instructions before installing and us-

ing your fireplace insert. Install and use only

in accordance with manufacturer’s installation

and operating instructions.

2)

Check your local building codes - Building

Inspection Department. You may require

a permit before installing your insert. Be

aware that local codes and regulations may

override some items in the manual.

WARNING: Careless installation is the ma-

jor cause of safety hazard. Check all local

building and safety codes before installation

of unit.

3)

Notify your home insurance company that you

plan to install a fireplace insert.

4)

Your fireplace insert is heavy and requires two

or more people to move it safely. The insert and

surrounding structure can be badly damaged

by mishandling.

5)

If your existing fireplace damper control will

become inaccessible once you have installed

your Regency Insert, you should either remove

or secure it in the open position.

6)

Inspect your fireplace and chimney prior to

installing your insert to determine that it is free

from cracks, loose mortar or other signs of

damage. If repairs are required, they should

be completed before installing your insert. Do

not remove bricks or mortar from your masonry

fireplace.

7)

Do not connect the insert to a chimney flue

servicing another appliance or an air distribution

duct.

6)

Alteration of the fireplace in any manner is not

permitted with the following exceptions;

a.

external trim pieces which do not affect the

operation of the fireplace may be removed

providing they can be stored on or within

the fireplace for re-assembly if the insert is

removed.

b.

the chimney damper may be removed to

install the chimney liner.

7)

Circulating air chambers (i.e. in a steel fire

-

place liner or metal heat circulator) shall not

be blocked.

8)

Means must be provided for removal of the

insert to clean the chimney flue.

9)

Inserts that project in front of the fireplace must

be supplied with appropriate supporting means.

10)

Installer must mechanically attach the supplied

label to the inside of the firebox of the fireplace

into which the insert is installed.

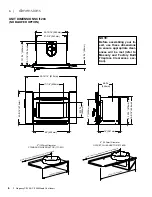

FIREPLACE

SPECIFICATIONS

Your fireplace opening requires the following

minimum sizes:

CI1203

Height:

19-5/8" (499mm)

Width:

25" (635mm)

Depth:

(w/ standard flue adaptor)

15-1/16" (383mm)

(w/ offset flue adaptor)

17-11/16" (449mm)

CI1253

Height:

23" (584mm)

Width:

25" (635mm)

Depth:

(w/ standard flue adaptor)

15-1/16" (383mm)

(w/ offset flue adaptor)

17-11/16" (449mm)

Emissions from burning wood or gas could

contain chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

"

WARNING

: This fireplace has been

converted for use with a wood insert only and

cannot be used for burning wood or solid fuels

unless all original parts have been replaced,

and the fireplace re-approved by the authority

having jurisdiction."

Important:

The blower to this appliance must be turned

off anytime the fuel door is opened. Prior to

turning the blower back on, ensure there are no

embers near the blower which may have fallen

onto the hearth when the fuel door was opened.

Once the fuel door is closed, the blower may

be turned back on.