- 20 -

Airflow Tests

(CoN’tD)

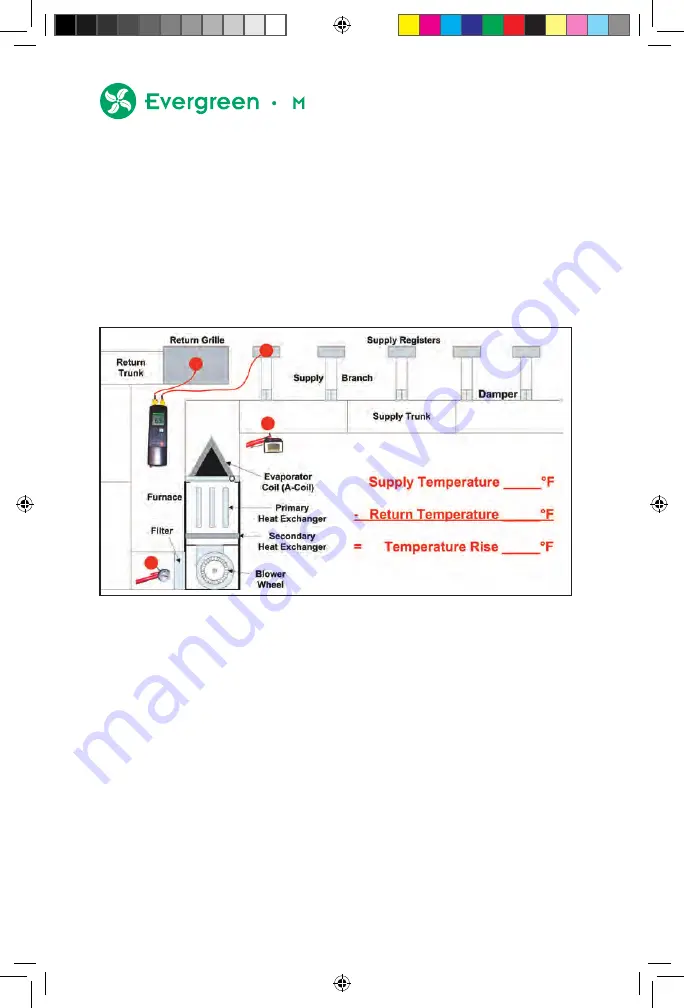

measuring temperature Rise

Temperature rise should be measured as close as possible to the HVAC

system in the return air inlet and in the supply out of the line of site of the heat

exchanger. The diagram below shows an example of an up flow system and

the recommended measuring points. Down flow (counter flow) and horizontal

flow systems follow the same parameters.

If access to the ductwork close to the furnace is not possible, use the closest

return grille and supply register. Analog or digital thermometers are accurate

enough for these readings. Some dual temperature meters will automatically

calculate the difference.

Temperature rise is calculated as the difference between the supply and return

temperature readings.

• Increase blower speed to lower the temperature rise.

• Decrease the blower speed to increase the temperature rise.

Example:

If the manufacturer’s data plate rating is for a 30 – 60 degrees Fahrenheit

temperature rise, and the actual measured rise is 65 degrees, the blower

speed will need to be increased. If the actual measured rise is 25 degrees, the

blower speed will need to be decreased.

®

I

Evergreen IM manual 01-13.indd 20

2/13/13 11:12 AM