Series TH80000 Spring Driven Hose Reels

Page 2

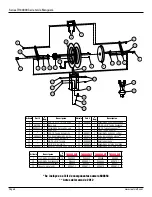

www.reelcraft.com

INSTALLATION INSTRUCTIONS

Warning:

Ensure that reel, hose, and

equipment are properly grounded. Use an

ohmmeter to check ground continuity.

MOUNTING

Caution:

Unless reel was specified

differently when ordering, maximum

installation height is 16 feet. Do not

exceed this distance.

Maximum Operating Temperature:

Medium pressure (2000 PSI) = 210°F (99°C)

1. Unpack and inspect reel for damage.

Turn by hand to check for smooth

operation. Check for completeness.

2. Configure reel for top, side or

bottom-wind hose dispensing by

removing bolts (2) from one side of

the guide roller bracket and loosening

the four guide arm bolts (3) on each

side of the hose reel. Rotate and

remove each guide arm then reinstall

in the desired configuration.

Caution:

When changing guide arm

positions, the U-bolt must be placed in

the proper location as instructed in

figure A on page 1. The reel can

“latch out” during use if this

instruction is not adhered to.

3. Position reel on floor, wall, or ceiling.

Secure into place using four (customer

supplied) bolts.

INSTALLING THE INPUT HOSE(S)

Warning:

Ensure that supply line pressure

does not exceed maximum working pressure

rating of reel. Apply pipe thread sealant where

applicable to all threads on standard reels. Do

not overtighten connection. Recommended

torque not to exceed 70 ft. lb.

Caution:

Use flexible hose connection at

input. Do not use rigid plumbing.

For twin hydraulic reels:

1. Apply thread sealant as directed and

connect swivels (12 and 15) to main

shaft inputs (5) on opposite sides of

the reel.

2. Connect customer supplied supply

line hose (4) to swivel input (15) as

indicated in illustration. Note that the

supply line and return line hoses can

be switched as long as caution is

taken when installing output hoses;

paying attention to hook -up locations

on goosenecks.

3. Thread sealant is not recommended

on swivel union fittings.

INSTALLING THE OUTPUT HOSE(S)

Warning:

Use extreme caution; reel

under tension. Avoid releasing latch

mechanism.

Caution:

Apply pipe thread

sealant where applicable to all threads on

standard reels. Do not overtighten connection.

Recommended torque not to exceed 70 ft. lb.

1. Manually turn sheave (6) until spring

is tight, back off 3 turns, then latch.

2. Route output hose(s) (7) through

roller bracket (1), U-bolts (8),

then through cutout (9) in spool as

indicated in illustration.

3. Connect output hose/s (7) to

gooseneck (10) paying special

attention to which gooseneck should

be used depending on application.

4. Verify U-bolt position conforms with

guide arm position using label inside

spool. Then tighten nuts (11) on

U-bolt (8).

5. Charge hoses. Momentarily open

control valve to purge hose of gases.

When fluid appears at control valve,

close valve. With hose fully charged,

release latch and wind output hose/s

onto reel.

6. Install bumper stop assembly.

ADJUSTMENTS

Warning:

Use extreme caution; reel

under tension. Avoid releasing latch

mechanism. If necessary, adjust spring

tension on reel by adding or removing

wraps of hose from spool, one wrap at a

time, until desired tension is obtained. Add

wraps to increase tension. Remove wraps to

decrease tension.

Caution:

When adding wraps of hose, add

just enough wraps to achieve the desired

tension without exceeding the winding mecha-

nism’s spring capacity. Properly tensioned

reels allow all hose to be freely removed from

the spool until the point of U-bolt contact.

Damage to the winding mechanism will result

if spring is over-tensioned.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to

replacing input/output hoses only. Refer all

other repairs to an authorized service

person or directly to Reelcraft. Failure to

do so can result in personal injury and/or

equipment damage and may void the

warranty.

Warning:

Rewind hose on reel,

then bleed pressure from system before per-

forming the following procedures.

Caution:

Remove all spring tension before disassem-

bling the hose reel. Do not attempt to open

the riveted spring case assembly.

1. Replace hoses in accordance with

procedures given in “Installation

Instructions” section of this manual.

2. All mating moving parts have been

factory lubricated as required.