Series SD10000 Spring Driven Reels

www.reelcraft.com

Page 7

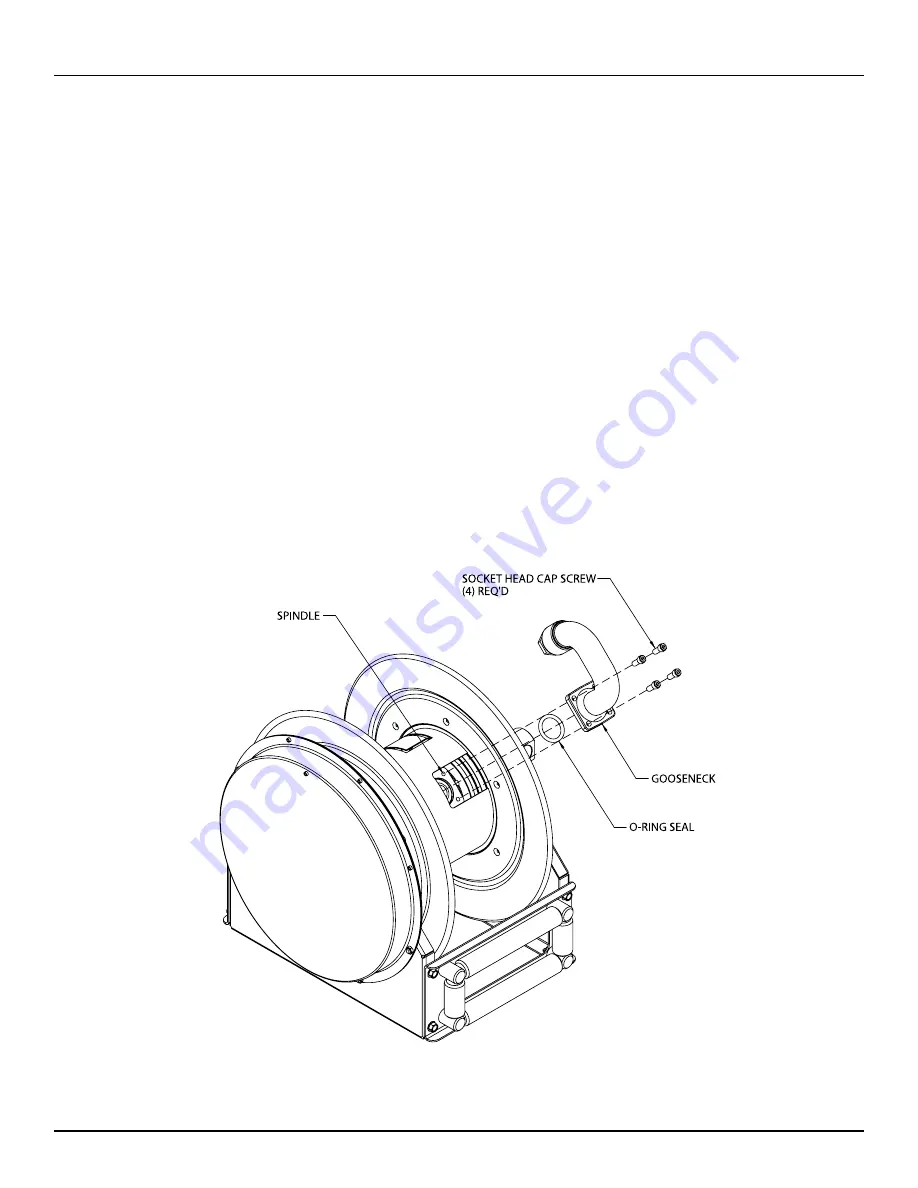

Fluid Path Static Seal

Your hose reel is suited to be used with Air, Water, Oil, and Various Fuels. If a substance incompatible with the seal inside

the fluid path is pumped through the reel, the o-ring seal between the gooseneck and spindle may degrade and cause the

fluid path to leak. Verify with Reelcraft Engineering Department for hose reel compatibility with questionable substances.

If a leak should occur, contact Reelcraft to establish proper o-ring replacement and follow the steps below for o-ring re-

placement.

1. Relieve the pressure and bleed the line of all fluid. It is recommended that the supply line be removed from the supply

source to eliminate the possibility of pressurized fluid injuries and/or accidental spills.

2. Pull the hose assembly completely from the spool and latch the reel.

3. Attach a C-clamp to the reel flange to help prevent the reel from unintentionally becoming unlatched and spinning

freely.

4. Remove the outlet hose from the gooseneck (optional).

5. Remove the four bolts attaching the gooseneck to the spindle.

6. Remove the gooseneck and o-ring from the fluid path spindle. Check the o-ring groove for debris and remove any re-

sidual fluid that may be present. All surfaces of the gooseneck and spindle should be clean and free of debris.

7. Replace appropriate o-ring by placing it in the groove of the spindle.

8. Replace the gooseneck and secure it in place with four socket head cap screw.

Fig. 5