2

The Reed Rotary™ Cutter is a very efficient tool for cutting many

different sizes of cast iron, ductile iron, and steel pipe, from 20" to

36". In most cases, the Rotary™ Cutter is a one person tool.

Fig. 1

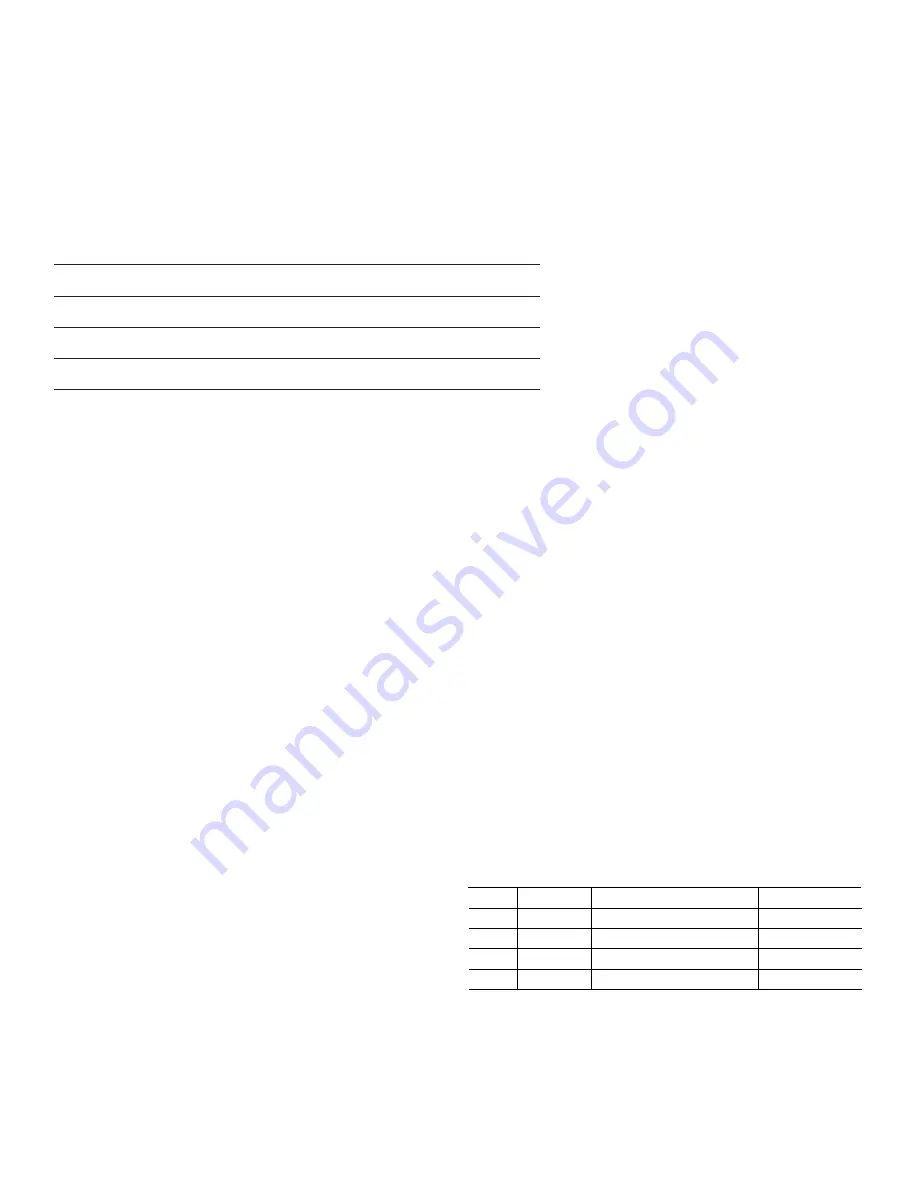

Cutter Wheel Reference Chart for Rotary™ Cutters

For best results and efficient operation, these instruc-

tions should be followed carefully:

1.

Determine the best type of cutter wheel to use for the pipe to be

cut by referencing Fig. 1.

2.

To change the cutter wheels, lay the Rotary™ Cutter on its side,

with the head of the wheel pin head pointing down. Next, lightly

tap the end of all wheel pins facing up, allowing them to drop out

far enough to enable the removal of the wheel pin. Prior to re-

moving the wheel pin completely, flip the Rotary™ Cutter over

and then remove each wheel pin. Line up the cutter wheels and

outboard roller and push the wheel pins back into the hole. Next,

seat the wheel pin into place with a light tap and repeat this

proceedure for all of the wheel pins.

3.

To set up for making a cut, loosen the nuts on the main screws

just enough to permit the cutter frame to slide over the end of

the pipe. (The main screws can also be slipped out of the frame

slot to permit the cutter to open and be placed around the pipe.

Re-engage the main screw with the frame slot to close the

cutter frame.)

4.

Position the cutter so the cutter wheels are in line with the cutoff

mark. Rotate the cutter until the weight of it is resting on the

spring-loaded guide fingers in the top half of the cutter frame. All

cutter wheels should at this time be away from the pipe, and the

arrow on the frame point in the direction of desired rotation.

5.

Slightly rock and wiggle the cutter until all four of the guide

fingers touch the pipe. This rocking motion makes the cutter sit

square on the pipe.

6.

Next, without disturbing the cutter position, tighten up the main

screw nuts EQUALLY by hand. Usually the two bottom wheels

will contact the pipe first. Continue tightening as the spring-loaded

guide fingers retract and permit the top wheels to contact the

pipe. Using the lug wrench on the operating handle, tighten the

one accessible nut as tight as possible while still being able to

rotate the cutter.

7.

Slipping the lug wrench over the most conveniently accessible

lug, rotate the cutter, one lug at a time in the direction of the

arrow, until the other nut is in position to be tightened. Recheck

the location of the cut and that the cutter is tracking properly.

Item

Reed

Std.

Blade Exposure

Code

Cat. No. Pkg.

Reed Cutter

Inches MM

Application

03530

RCS8-36

4

LCRC8; LCRC12; LCRC16; RC20;

0.635

16.1

Steel; Stainless Steel

RC24; RC30; RC36

03535

RCI8-30

4

LCRC8; LCRC12; LCRC16; RC20;

0.500

12.7

Cast Iron; Ductile Iron (manual)

RC24; RC30; RC36

03545

RCDX

4

LCRC8; LCRC12; LCRC16; RC20;

0.531

13.5

Heavy Cast Iron; Ductile Iron (PRC)

RC24; RC30; RC36

03550

RCX

4

LCRC8; LCRC12; LCRC16; RC20;

0.800

20.3

Heavy Wall Steel; Stainless Steel

RC24; RC30; RC36

Operating Instructions

8.

To complete the cut from this point, keep rotating the cutter and

at every half revolution, tighten each main screw nut one

quarter to one half turn. (For the RC30 or RC36, it may be

advisable to have two workers: one person to tighten the nuts

and one to rotate the cutter.) It is important to complete the

cut without pausing and to maintain consistent pressure.

9.

Steel pipe must be cut all the way through the wall. Cast iron

pipe, depending on age and hardness, will snap off clean and

true after about one-fourth of the wall has been penetrated.

Ductile iron, being very tough, usually snaps off after one-third

to one-half the wall has been penetrated.

10. When cutting cast iron pipe, after hearing the first

snap or crack in the pipe, continue tightening the

nuts to maintain maximum pressure on the pipe

until complete cutoff occurs. If a support can be

maintained on the pipe while cutting, such as with

a crane, hydraulic jack, etc., it will often cut the

operation time in half by inducing the fracture to

occur sooner and to run clear around the pipe

instead of part way.

11. When cutting into a section of cast iron pipe, that has been

buried in the ground for a long time, the line may be under com-

pression from various causes and the slightly jagged fracture of

the cuts may resist lifting the cut piece out. One way around this

difficulty is to make three cuts instead of two. Make a third cut

about 2

1

/

2

” inside one of the end cuts. A sledge hammer will

break out the two and a half inch section and then the bigger

piece will lift out easily. When cutting cast pipe under compres-

sion, the cutter must be fed and rotated until all outboard rollers

are in contact with the pipe, to be sure of complete fracture.

12. The cutter is designed not to break under cutting loads. The

handle will bend first.

13. Certain brands of ductile iron pipe are softer than others and

lend themselves to faster and easier cutting with RCS8-30

cutter wheels for steel pipe. If cutter wheel breakage is not

excessive, the substantial time and labor savings may very well

justify this.

BADLY CRUSTED AND RUST SCALED PIPE: Remove the rust

and scale from the area to be cut with a Reed Descaler (Fig. 2). A

hammer and chisel or coarse file may also be used. This will help

save cutter wheels and cutting time; and helps to square the cutter

on the pipe to ensure tracking.

Fig. 2

PIPE DESCALERS

Cat. No.

Item Code Pipe Capacity

Length

DS12

08000

3 - 12 in

70 - 300 mm

32 in

810 mm

DS36

08006

3 - 36 in

70 - 910 mm

44 in

1110 mm

DS12B

08008

3 - 12 in

70 - 300 mm

45 in

1143 mm

DS36B

08010

12 - 36 in

300 - 910 mm

72 in

1829 mm