7

The following list outlines conditions that are unique to factory recalibration:

1. Unlike the field scaling procedures, there are no software under and over

range indications while performing a factory recalibration. Therefore,

care must be taken to insure the selected range extents are not exceeded.

The minimum scale and full scale calibration values must be set to the

extents of the range being calibrated.

For example: If the Input Range DIP switches are set for the 4-20 mA

range, minimum scale must be set at 4 mA, and full scale must be set

at 20 mA.

2. At least one input calibration must be completed before calibrating any

output range. When calibrating the input voltage range, it is

recommended that a range above 1 V be used to provide better accuracy.

3. If multiple input or output ranges are to be calibrated, DO NOT

REMOVE POWER TO CHANGE THE RANGE. Place the appropriate

Field/Fact. DIP switch; S1-1 for outputs, and S1-2 for inputs to the down

position, and set the remaining DIP switches for the range to be

calibrated.

Note: Be sure to change the terminal wiring to match the

Input or Output range DIP switch settings before performing the

calibration procedure. Set calibration source to 0 V or 0 mA before

changing wiring.

INPUT RECALIBRATION

1. To enter the factory calibration mode, set switches S1-1 and S1-2 down, S1-

3 through S1-5 up, and S1-6 through S1-10 down.

2. Connect a signal source to the correct input terminals based on the

maximum signal input to be calibrated. If an output range will be calibrated

after the input range is calibrated, connect a voltage or current meter to the

appropriate output terminals at this time.

3. Apply power to the IAMA. After the version number indication, the green

LED will flash rapidly for 2 seconds indicating the factory calibration mode

has been entered. Allow the IAMA to warm up for 5 minutes minimum and

follow the manufacturer’s warm up procedure for the calibration source.

4. Set the Input Range DIP switches to the desired input range according to

Table 3.

5. Complete Steps 2.6 through 2.10 of Input Scaling Using Field

Configuration.

Note: There will be no over or under range indication of the

LED’s during this procedure, so use care not to exceed the range extents.

6. If an output is to be calibrated, continue from #2 of Output Recalibration

below. If no further input or output calibration is to be completed, return S1-

1 and S1-2 to the down position and remove power from the IAMA. Apply

power and check for accurate operation of the newly calibrated range or

ranges.

OUTPUT RECALIBRATION

1. Complete 1 through 5 of the input recalibration procedure for at least one

range.

2. For current output, set 20 mA/1 mA switch (S2) to desired full scale output.

(20 mA - on; 1 mA - off)

3. Set Output Field/Fact. switch (S1 switch 1) to the off position.

4. Set the Output Range DIP switches to the desired output range according to

Table 2.

5. Complete Steps 4.10 through 4.14 of Output Scaling Using Field

Configuration.

Note: There will be no over or under range indication of the

LED’s during this procedure, so use care not to exceed the range extents.

6. If no further calibration is to be completed, return S1-1 and S1-2 to the down

position and remove power from the IAMA. Apply power and check for

accurate operation of the newly calibrated range or ranges.

RECALIBRATING FACTORY STORED VALUES

WARNING: Read the complete procedure at least

once before attempting to recalibrate the factory

values. This procedure should only be

performed due to factory checksum error or

unacceptable error. This procedure should be

performed by qualified technicians using

accurate calibration equipment.

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate company numbers listed.

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style mounting rails, including G profile rail

according to EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5 and 35 x 15. The unit should be installed in a

location that does not exceed the maximum operating temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

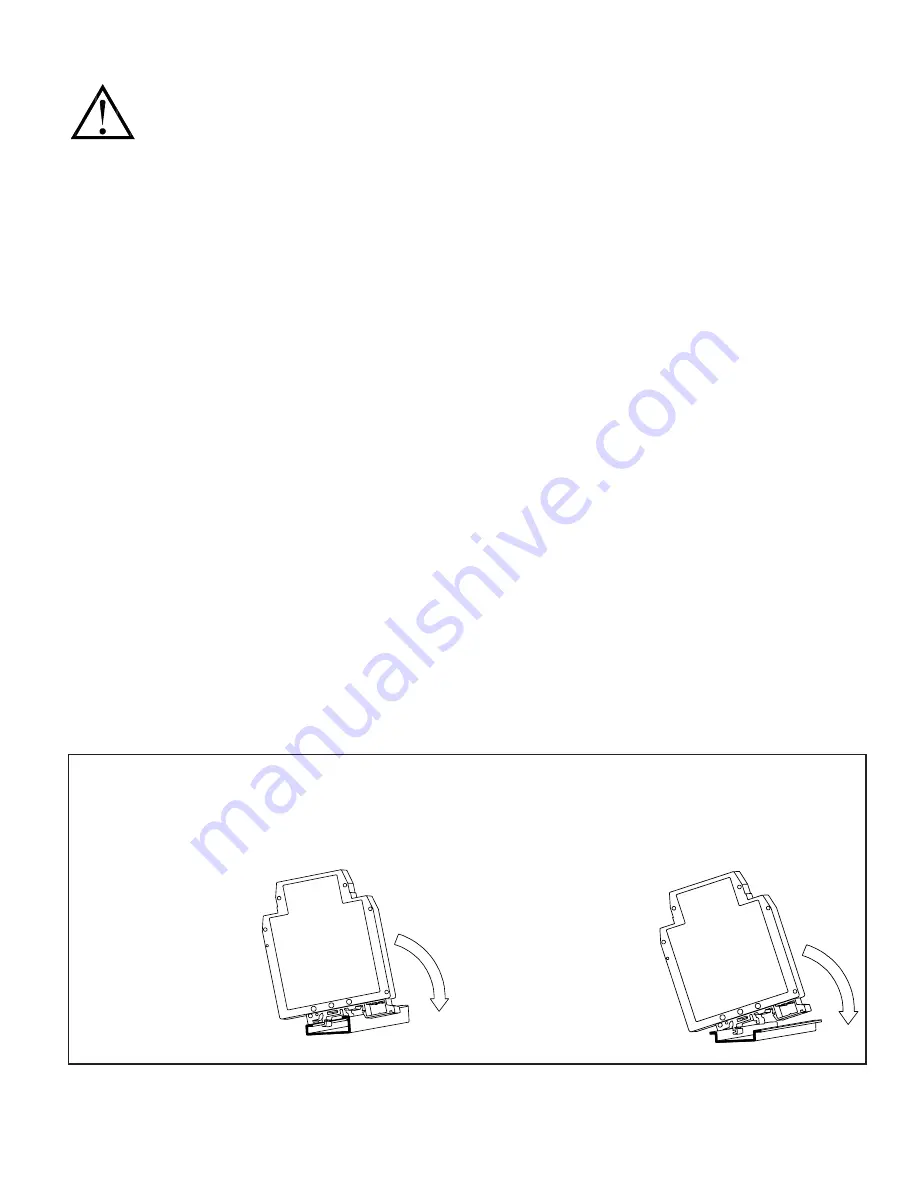

G Rail Installation

To install the IAMA on a “G”

style DIN rail, angle the module

so that the upper groove of the

“foot” catches under the lip of the

top rail. Push the module toward

the rail until it snaps into place.

To remove a module from the

rail, push up on the bottom of the

module while pulling out and

away from the rail.

T Rail Installation

To install the IAMA on a “T”

style rail, angle the module so

that the top groove of the “foot”

is located over the lip of the top

rail. Push the module toward the

rail until it snaps into place. To

remove a module from the rail,

insert a screwdriver into the slot

on the bottom of the “foot”, and

pry upwards on the module until

it releases from the rail.