16 | 28

M0170.docx | Rev 1.2 | Modified on 20/04/2016 | © Remote Control Technologies P/L

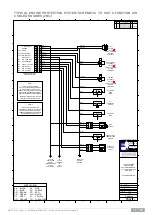

ALERT FUNCTION IDENTIFICATION

LABELS

PART NO.

LABEL

PART NO.

LABEL

5636

6143

0427

1526

1372

5630

5629

5635

0426

5634

0437

5637

0428

1413

0442

4352

0453

5638

0486

5633

3465

4350

3144

5631

5785

5632

5780

4348

5782

1411

5784

4349

5779

5628

5781

1417

5783

8424

5778

1368