5

IG2 Introduc�on

This manual provides informa�on about the IG2 Ion Source Package, which comprises the Model 04

-

165 2 kV Backfill Ion Source and the Model 32

-17

5 Ion Source Control, as well as addi�onal op�ons

available for the IG2.

The RBD 04

-

165 Ion Source is interchangeable with the PHI® 04

-

161 and 04

-

162 ion guns. The RBD

32-17

5 Ion Source Control is interchangeable with the PHI® 20

-

045 control. As a result, the RBD

Model 04

-

165 works with the PHI 20

-

045, and the PHI 04

-

161 and 04

-

162 ion guns work with the

RBD Model 32

-17

5. This manual discusses the op�ons available for the IG2, the items required to use

RBD’s components with corresponding PHI components, as well as differences in opera�on or other

aspects of a component’s use.

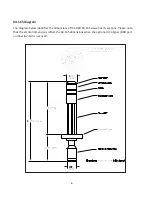

RBD Model 04-

165 2 kV Backfill Ion Source

The Model 04

-

165 2 kV Backfill Ion Source generates an energe�c inert gas ion beam for sputer

-

etching solid surfaces. The source requires a sta�c pressure of 5x10

-5

torr with an inert gas such as

argon. Ions are generated by electron impact within the ion source’s dual filament ioniza�on

chamber and are then focused at the target with energies of up to 2

K

eV. The impurity content of the

ion beam is minimized by using an off

-

axis filament geometry. A focusing lens permits high ion

current density to be obtained for a given opera�ng pressure and source

-to-

sample distance. A dual

tungsten filament assembly permits con�nued opera�on when the first filament opens. The

expected life�me of the filament assembly is several years under normal usage at the recommended

opera�ng condi�ons. The filament assembly is easily replaced in the field.

The 04

-

165 fits on a standard 2.75" flange, which has a 1.35" ID and a 1.5" OD.

04-165 Specifications

Specification

Description

Source Type

Hot

filament

electron

impact

(dual

filament,

backfill

type)

Beam Energy

.5

kV

to 2

kV

Minimum Beam Diameter

»

at 25 mm working distance

2.5

mm

FWHM

(at target)

»

at 50 mm working distance

3.5

mm

FWHM

(at target)

Maximum Total Target Current

≥10

μA

at

V

B

= 2

kV.

Maximum Current Density

»

at 25 mm working distance

≥200

μA/cm

2

when

V

B

= 2

kV

»

at 50 mm working distance

≥100

μA/cm

2

when

V

B

= 2

kV

Mounting

Standard

2.75"

CF

bored

flange

OD,

1.35"

ID

minimum

tube required

Flange to End of Optics

7.00"

or

9.25"

(2.25"

less

with

optional

x

-

y

aligner)

Working Distance

Typically

50

mm

end-

of

-optics-to-

target