Building Instructions JIMMY

Page

van

15

20

Finishing

Wing and fuselage are now ready to get their final finish. Sand everything smooth, and

round the corners of the fuselage. Do not overdo it, avoid reducing the glue areas too

much. The simplest way to finish all surfaces and open structures is to use iron-on

covering film. It is important to apply the covering at a low temperature setting of your

iron to reduce initial shrinking, and only when everything is attached properly raise the

temperature to tighten the covering and remove any wrinkles. This is especially important

with open structures, i.e. the wing, which should be covered at low setting on top and

bottom first, and only then raise the setting to tighten it evenly. Be careful not to introduce

warping of the wing, but when you do you can iron those out by ”counter-warping” the

wing by weighting one half down on the board and carefully rotate the other tip by hand,

reheat the covering and let it cool before you release it.

It will be difficult to describe the details of iron-on covering in a few words, best is to let

an experienced modeller show you how it’s done, or refer to the instructions of the iron-

on film supplier, e.g. Solarfilm, Oracover and others.

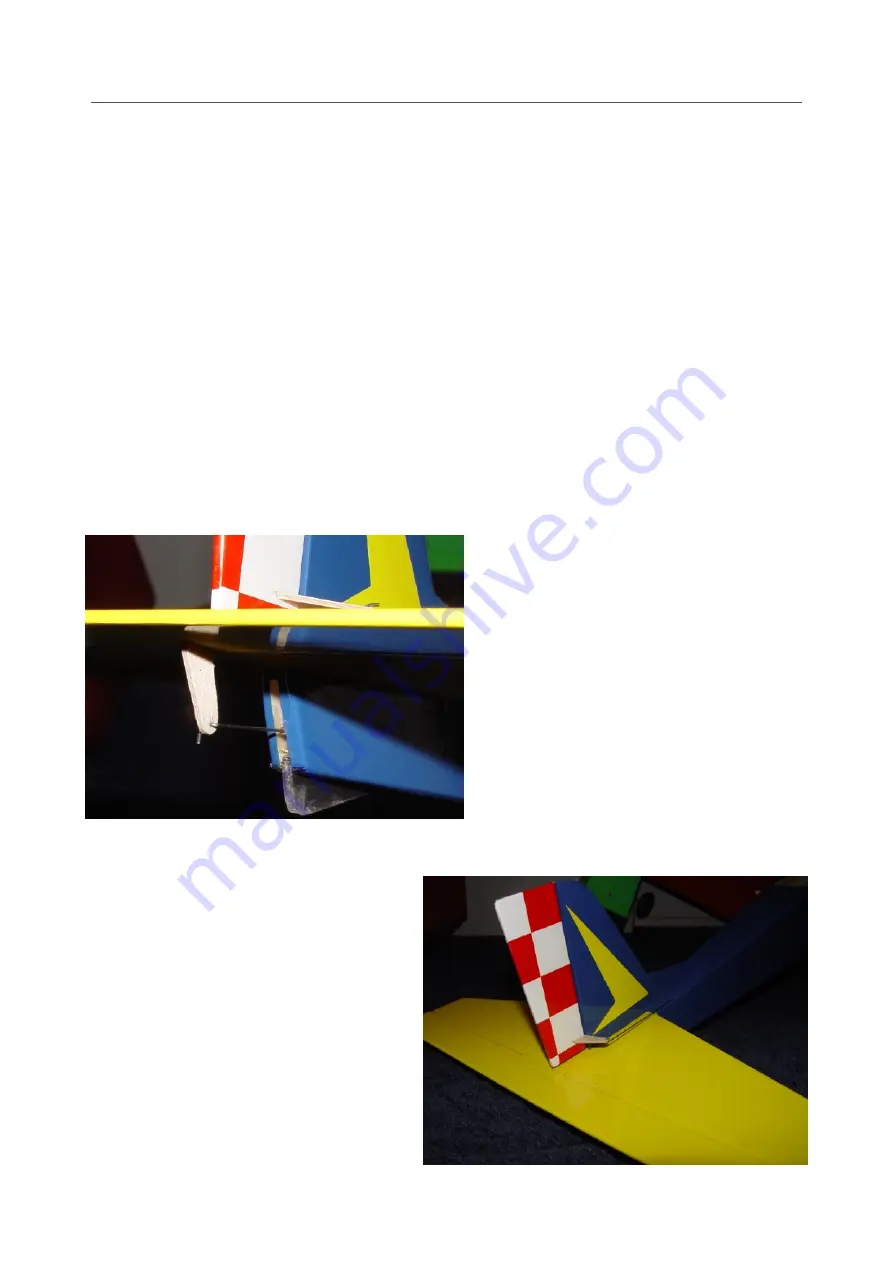

As mentioned before, the tail surfaces

are best covered before final assembly.

Leave the area to be glued to the

fuselage free from covering.

Mark the position of the rudder horns,

cut a slot and glue the horns to the

control surfaces. Check the drawing for

the exact positioning of the horns.

Attach the elevator to the stabiliser with

sticky tape. Stick the tape to the top of

the stabiliser, leaving one half past the

edge to stick to the elevator. To ensure

a minimum hinge gap and a maximum

deflection angle, hold the elevator in a

downward attitude against the rear

edge of the stabiliser and push down

the tape onto the elevator.

Attach the rudder in the same way, pay

attention to the bevel on the front edge

of the rudder.