18

ered by 5°F. Then for each 24-hour period that heater

demand is less than one half of DA, the setpoint is

increased by 1°F until the original value is restored.

The default value is 70%. The PERFORMANCE DATA

screen titled Temp Reduced by ASL Strategy will show

a value other than zero if this strategy is in effect.

Default Value 70.

Return Temperature

The return sensor is used to compensate for seasonal

changes in loop heat loss. The strategy may raise the

supply/branch temperature in cold weather to ensure

that the last rooms on the loop have hot enough water

even during low demand periods.

R0 - SELECT - Return Sensor Installed:

Select YES

if this sensor is connected, otherwise select NO.

Default is YES.

R1 - SELECT - Minimum Return Temperature:

If the

return temperature drops below this value then the

return sensor strategy will be activated. Above this

value, the strategy will have no effect on desired tem-

perature.

Default Temp 108°F.

R2 - SELECT - Return Sensor Response:

This is a

multiplier which increases the desired temperature as

the return temperature drops. Example: desired = 130,

return = 100, R1 (above) = 102, R2 = 5. The desired

temperature will be increased to 140 = 130 + (102-

100) X 5.

Default Value is 1.

Branch Temperature - Not

Used

B0 - SELECT - # of Branch Sensors Installed:

Not

used.

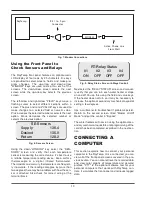

Relay Sequencing

(4-Stage Control)

HS - SELECT - # of Heaters:

Enter 1 thru 4 for the

number of heaters connected to relay outputs 1 thru 4.

This allows the RayTemp to correctly sequence

heaters and record demand.

SP - SELECT - Stages Per Heater:

Enter the number

of stages in each heater, from 1 to 4.

SQ - SELECT - Firing Options:

Four options for

stage sequencing are available. Select number 1, 2, or

3 as follows:

#1 No Lead/Lag: Stage 1 of heater #1 always fires

first. The remaining stages and heaters will fire in

order as demand increases.

#2 24-Hour Rotation: At midnight each day, the firing

order is rotated to the next heater. This distributes

the work load equally among all heaters.

#3 Lead/Lag & Rotate: With this option, heater #1

always fires first, then the remaining heaters fire in

rotation. Since some flue designs require heater

#1 to fire first; this option meets this requirement

while still providing limited rotation.

US - SELECT

- Use 24volt on/off sensing.

Do not use.

DD - SELECT - Differential:

Increasing DD lengthens

the heater burn cycle; decreasing DD improves tem-

perature stability. For instance: desired=140,

deadband=1, heater turns off at 141 and on at 139.

This deadband applies equally to all stages.

D1 - SELECT - Temperature Delay Between Stages

(In addition to differential setting):

This value caus-

es successive output stages to come on according to

the deviation to target temperature. D1 activates addi-

tional heaters or stages as demand increases. For

example with a setpoint of 140°F and a temperature

delay of 1°F, stage 1 will fire at 140, stage 2 at 138,

stage 3 at 136, etc., assuming 2°F deadband.

RL - TEXT - Relay Logic (1-12):

The default value is

++++++++++++.

Relay Sequencing

(2-Stage Control)

HS - SELECT - # of Heaters:

Enter 1 or 2 for the num-

ber of heaters connected to relay outputs 1 and 2. This

allows the RayTemp to correctly sequence heaters

and record demand.

SP - SELECT - Stages Per Heater:

Enter the number

of stages in each heater, 1 or 2.

NOTE:

If you select minus (-) and the RayTemp

loses power or fails, then the heater or pump will

remain off!!! Edit text with SPACE, BACKSP, F4, and

F5 to return to a plus setting.