Wuhan Raycus Fiber Laser Technologies CO., Ltd.

20QS/30QS

Pulsed Fiber Laser User’s Guide V1

4

b)

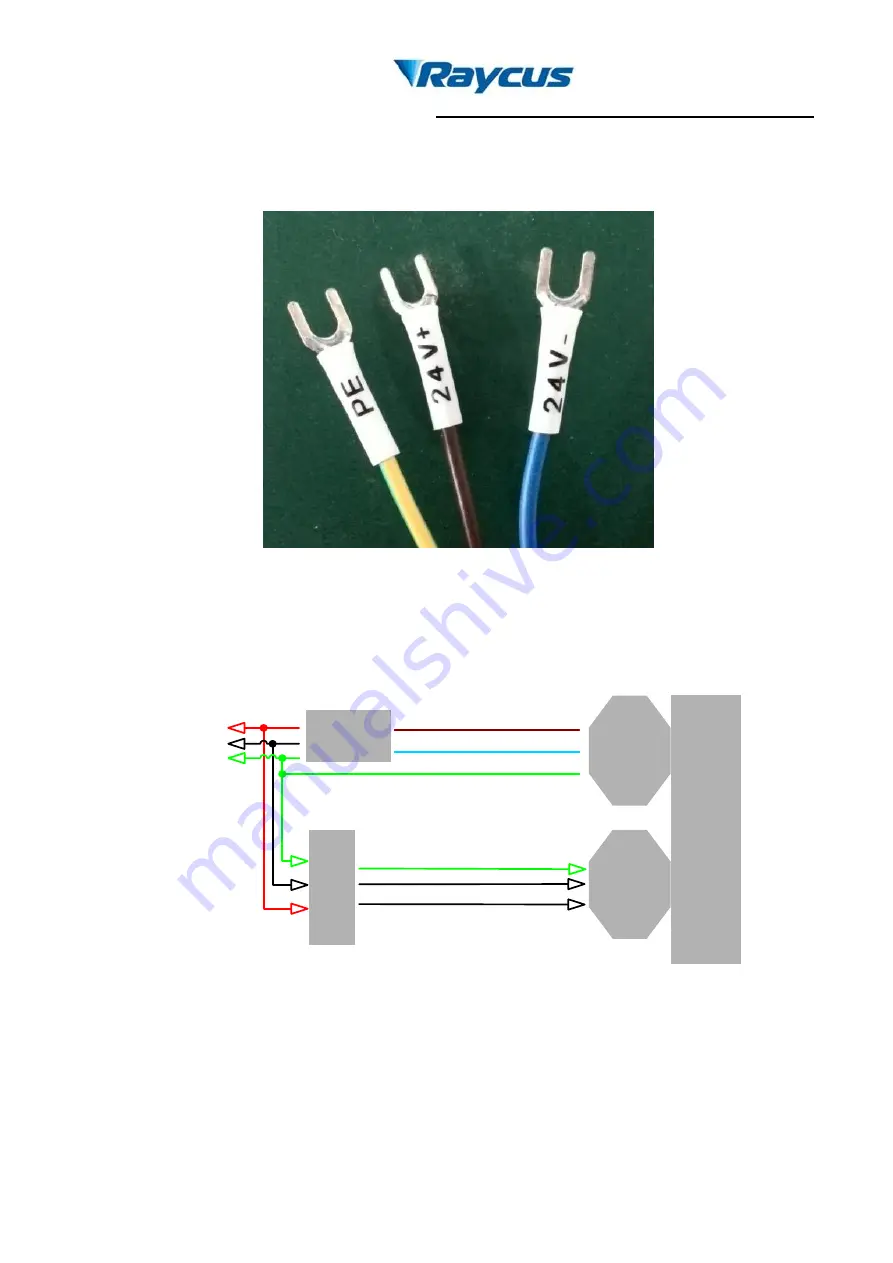

Connect the power line to 24VDC power and ensure enough DC output power.Keep it

clear to the polarity of the electric current: anode-brown; cathode-blue; PE-yellow and

green. The definition figure is shown in Fig. 3.

Figure 3. Definition of power line wires

c)

Make sure that the interface of the external controllermatches the laser and the control

cable is well connected to the laser’s interface. The recommended electrical connection

is shown in Fig. 4.

User

’s

cont

rolle

r

DB25

Controller

interface

Power

supply

wire

Laser

Module

24V+(Brown)

L

N

GND

External GND

24V

power

supply

24V-(Blue)

Figure 4. Schematic of recommended electrical connection

d)

The bending radius of the delivery fiber should not less than 15cm.

3.

Control Interface

There are DB9 and DB25 interfaces at the rear of the laser. The DB9 is a RS232 interface

only used for debugging, no needs to connect. And DB25 is the joint interface connecting control

24V+

GND

24V-