RG13II Operation • Maintenance • Parts

30

Grease and Oil Buildup - Remove

For cleaning with a hot water cleaning device, use a spray

steam with a pressure not exceeding 426 psi (2937 kPa)

to prevent damage to painted areas of the components.

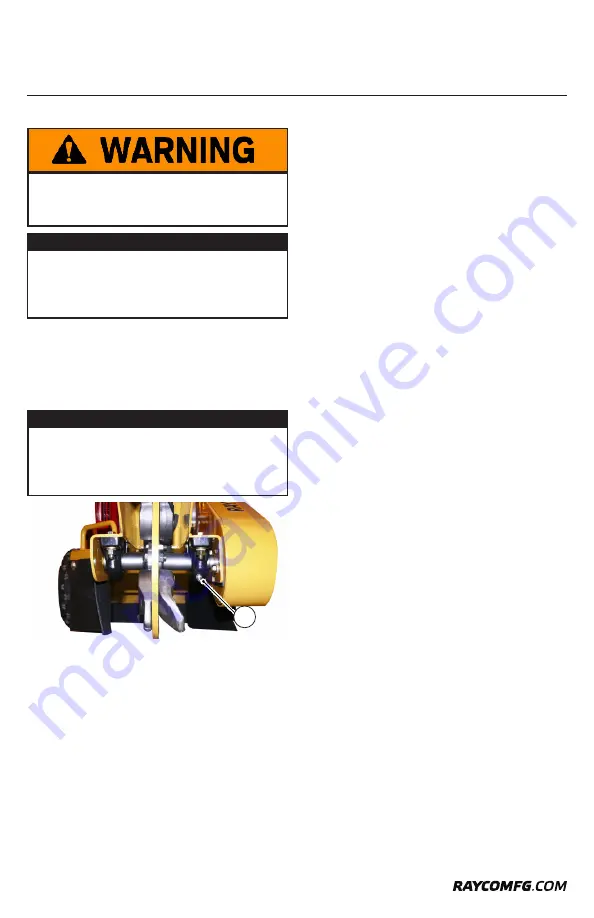

Lubricate the Fittings

Lubricate the two fittings as shown(1) (One on each cutting

wheel bearing). Slowly add grease until you see new grease

purging out of side bearing. Performing this procedure every

10 hours will prevent debris and moisture from entering and

damaging the bearing.

Lubricating Grease

All Rayco stump cutters are completely serviced at the factory

before shipping. The operator should check all grease fittings

to familiarize himself with their location and acquaint himself

with the correct service schedule.

Use the normal shutdown procedure (See “Operating

Instructions”), before lubricating the machine.

Cutting Wheel - Check

One of the most critical elements of the stump cutter are

the cutting teeth. They are also the most subject to damage

and wear. In the course of cutting stumps they not only make

contact with wood, but also encounter a numerous assortment

of abrasives and objects in the stump’s environment, such as

dirt, stones, and occasionally a large rock or buried scrap.

The loss of and wear of teeth can significantly impair the

efficiency of a stump cutter and also result in overexposure

of other teeth, resulting in premature failure or wear. Therefore

it is important to make frequent observation of the condition

of all of the cutting teeth, and replace or have sharpened any

missing and significantly worn teeth, as soon as feasible.

Read all of the instructions on the following pages before

beginning to change cutting teeth.

Using Rayco Teeth

Rayco Manufacturing Inc. recommends only genuine Rayco

Cutting Tools for use on Rayco Stump Cutters and Forestry

Mowers. The use of non-Rayco cutting tools or cutting

wheels will void the machine warranty. Rayco’s cutting tools,

cutting wheels, and mower rotors are specifically designed

to provide optimum performance in many ways. The use of

non-Rayco parts will compromise this optimum performance.

• Safety: Rayco’s cutting tools are always attached with at

least two fasteners. This redundant fastening system is

far safer than those systems employing only one fastener.

Rayco’s cutting tools are also more visible than some of

the other cutting tools that are available. Some of the

cutting wheels available today are “transparent” which

can lead to an operator or bystander becoming confused

as to the actual limits of the cutter tool.

• Proper Balance: Rayco’s cutting wheels and mower

rotors are designed to achieve a dynamic balance that

avoids vibration. Using other cutting tools can set

up vibrations that will harm the machine’s structure &

reduce bearing life.

• Number of Teeth for Depth of Cut: Rayco’s cutter wheels

are designed to provide an economical cutting wheel

assembly solution. The teeth are spaced to provide a

maximum depth of cut for the number of teeth on the

wheel. Some of the wheels available today use a large

quantity of teeth to get the same depth of cut that a

Rayco wheel will achieve with half the teeth. While the

individual tooth cost may be less, the overall costs are

more. Additionally, having too many teeth in the stump

at any one time can lead to aggressive “grabbing” of the

stump, causing the stump cutter to violently hop. This

can cause injury to both man & machine.

• Tooth Projection: Rayco’s stump cutter teeth are

specifically designed to ensure that the carbide tip can

Maintenance

ACCUMULATED GREASE AND OIL ON A MACHINE

IS A FIRE HAZARD. REMOVE SUCH DEBRIS WITH

STEAM CLEANING OR HIGH PRESSURE WATER.

NOTICE

When cleaning the machine the use of mild soap

and water must be used for the first 90 days. Harsh

cleansers or solvents will strip paint off machine.

After 90 days stronger cleaners may be used.

NOTICE

Pump grease in slowly, and carefully to prevent

damage to the bearing seals. Use extreme caution

when using a high pressure or high volume grease

gun.

1