The appliance is delivered in a fully assembled condition

with the exception of the following items which are

supplied separately packed and require assembly.

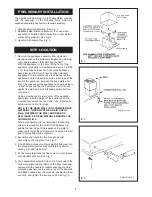

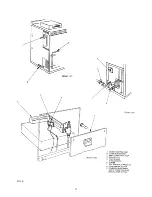

1. Draught Diverter Assembly - See Fig. 3.

2. Appliance Rear Distance Bracket - (For use when

appliance is installed 25mm away from a rear wall of

combustible material). See Fig. 4.

3. Handrail & Brackets. See Fig. 5.

1. Remove the appliance assembly from its transit

wooden pallet by the temporary location of a sloping

ramp board between the pallet and the floor.

With the appliance on the floor, lift the front of the

appliance (manually or crowbar) and insert a 1in BSP

x 1m long tube between the front of the appliance

base plate and the floor. Draw the tube balanced

appliance forward until the tube is at the rear of the

appliance and then insert a second similar tube at the

front of the appliance, between the base plate and

floor. The tube supported appliance can now be slowly

“rolled” across the floor and positioned with its back

against the wall, and in its intended position for flue

connection.

Using a crowbar at the rear corner of the appliance

base plate, take the weight of the appliance on the

crowbar and remove the rear roller tube, followed by

similar action on the front tube.

NOTE: IF THE REAR WALL IS OF COMBUSTIBLE

MATERIAL, THERE MUST BE AN AIR GAP OF

25mm BETWEEN THE WALL AND REAR OF

APPLIANCE. FIT REAR DISTANCE BRACKET AS

SHOWN IN FIG. 4.

Wherever possible, it is recommended that skirting

board is removed for the width of the appliance to

enable the rear edge of the appliance top-plate to

make contact with the vertical wall, and avoid a rear air

gap (Combustible walls excepted).

2. Assemble and locate the flue draught diverter

assembly on the top plate. See Fig. 3.

3. Fit a 600mm minimum vertical height of flue pipe into

the draught diverter flue socket before any bends,

sealing joint with fire cement.

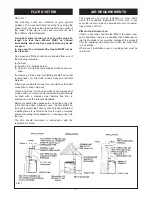

4. Connect and terminate the flue system in accordance

with standard practice. See Fig. 1.

5. The handrail brackets are held on the front ends of the

cooker top-plate casting. Remove the travel nuts and

replace with the handrail brackets ensuring the fibre

protecting washers are in position. Insert the handrail

with fitted endcaps into the brackets, positioning them

correctly, and tighten the locating bolts. See Fig. 5.

8

PRELIMINARY INSTALLATION

SITE LOCATION

FIG. 3

FIG. 4

FIG. 5

DESN510454 ‘A’