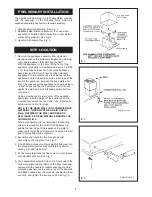

The following notes are of particular importance:-

Pipework should be insulated to help prevent heat loss

and possible freezing, particularly where pipes are run

through roof space and ventilated under floor spaces.

Cisterns situated in areas which may be exposed to

freezing conditions should also be insulated.

Draining taps must be located in accessible positions to

permit the draining of the whole system. Including the

appliance and hot water storage vessel.

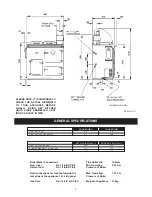

The appliance boiler section should be connected to a

cistern water supply, subject to a maximum head of

18.0m.

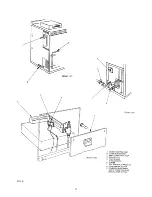

The hot water storage vessel should be insulated,

preferably, with not less than 75mm thick mineral fibre, or

its equivalent.

The use of horizontal pipe runs should be avoided

wherever possible in order to prevent the collection of air

in the system. If horizontal runs are unavoidable, the

pipes should rise upwards in the direction away from the

appliance.

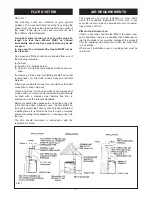

Hot Water Storage Vessel

It is recommended that an indirect 140 litre hot water

storage cylinder of the double feed type should be lagged

and fixed vertically as near as possible to the appliance.

The water draw-off pipes to the taps must be dead leg

connection from the vent/expansion pipe. A drain tap must

be fitted t the lowest point of the system.

Note: The appliance MUST not be operated if the

water system is put out of operation or has been

drained.

Water Connections

The two Rp1 (1in BSP int) flow and return connections are

located towards the rear edge of the appliance left hand

side panel, and pipe connections should be made with R1

(1in BSP ext) x 28mm dia copper compression fittings.

Gravity Domestic Hot Water

The 28mm O.D. primary flow and return pipe must rise

continuously from the boiler section to the cylinder to

ensure good gravity circulation and extended to provide

an open vent. The 28mm O.D. primary flow and return

pipes must not exceed 10m in length. Pipe runs in excess

of 5m must be lagged.

7

WATER CIRCULATION SYSTEM