Use and maintenance manual for stoves with touch remote

Pag.13

Rev.0 05/12/2022

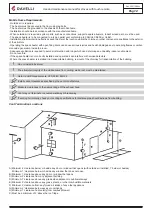

Examples of installation

This type of installation (see Pic. 4) requires an insulated flue, as all the smoke pipe has been installed outside the house.

In the lower part of the flue, a union tee has been mounted with an inspection cap.

A 90° bend should not be installed as the first initial piece as the ashes would quickly obstruct the passage of smoke, causing prob-

lems for the draught of the flue. (See Pic. 5).

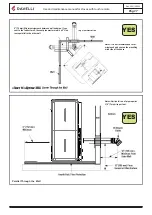

This type of installation (se Pic. 6) does not require an insulated flue as the smoke tube has been assembled partly inside the

house and partly inside an existing flue.

In the lower part of the flue a union tee has been installed with a peephole cap.

A 90° bend should not be installed as the first piece, as the ash would quickly block the passage of smoke, causing problems for

the draught of the flue (See Pic. 5).

Please note the use of 2 45° bends, to guarantee that the ash falls in the union tee with a peephole.

Pic. 4

YES

Protection from rain

Insulated flue

Union tee for condensation

907,8

443,9

39,1

345

18,2

35,1

190

40

352

20

398,8

278,7

956,3

187,5

328

35

80

107

83

478,9

453,7

Mod.

DESCRIZIONE

Data

Dis.

Appr.

MODIFICHE

54000-00-001

-

MOD.

_

_

A1

(SCHEET)

FORMATO

LISA 2007

85.607

----

COMPLESSIVO STUFA

TOLLERANZE GENERALI PER QUOTE LINEARI, ANGOLARI, SMUSSI E

RACCORDI, CLASSE FINE UNI EN 22768-1, DOVE NON INDICATE

1:5

FCH

P.Belotti

venerdì 14 settembre 2007

SCALA

(SCALE)

DENOMINAZIONE

(DENOMINATION)

MATRICE DI PIEGA

will be legally pursued.

diritti a rigore di legge.

and must not be released to other parties without written consent any infringement

in any way utilized for the manifacture of the component of unit herein illustrated All proprietary right reserved by Society ECOTECK s.r.l. This drawing shall not be reproduced or

ne venire comunicato a terzi o riprodotto. La Societa' proprietaria tutela i propri disegno non potra' essere comunque utilizzato per la costruzione dell' oggetto rappresentato Proprieta' della Societa' ECOTECK s.r.l. Senza autorizzazione scitta della stessa, il presente

MODIFICARE SOLO SU CAD

(CHECKED)

CONTR.

(WEIGHT)

PESO Kg

DIS.

MATERIALE

(MATERIAL)

(DESIGNER)

DATA

(DRWG NR.)

N. DISEGNO

(DATE)

CAD DRAWNING HANDLING ON CAD SYSTEM ONLY

MODELLO

(MODEL)

TRATTAM. SUPERFICIALE

Posizione file di disegno:

X:\ECO-PROGETTI\00_STUFE\ARCHIVIO-VALIDI\MODELLI-SW\

Posizione modello 3D:

X:\ECO-PROGETTI\00_STUFE\ARCHIVIO-VALIDI\MODELLI-SW\

Ultimo salvataggio di:

pbelotti -

Data ultimo salvataggio:

mercoledì 3 dicembre 2008 10.28.48

Via Kupfer 25035 Palazzolo S/O - BRESCIA - ITALY

Pic. 5

Ash deposited in the 90° bend

NO

907,8

443,9

39,1

345

18,2

35,1

190

40

352

20

398,8

278,7

956,3

187,5

328

35

80

107

83

478,9

453,7

Mod.

DESCRIZIONE

Data

Dis.

Appr.

MODIFICHE

54000-00-001

-

MOD.

_

_

A1

(SCHEET)

FORMATO

LISA 2007

85.607

----

COMPLESSIVO STUFA

TOLLERANZE GENERALI PER QUOTE LINEARI, ANGOLARI, SMUSSI E

RACCORDI, CLASSE FINE UNI EN 22768-1, DOVE NON INDICATE

1:5

FCH

P.Belotti

venerdì 14 settembre 2007

SCALA

(SCALE)

DENOMINAZIONE

(DENOMINATION)

MATRICE DI PIEGA

will be legally pursued.

diritti a rigore di legge.

and must not be released to other parties without written consent any infringement

in any way utilized for the manifacture of the component of unit herein illustrated All proprietary right reserved by Society ECOTECK s.r.l. This drawing shall not be reproduced or

ne venire comunicato a terzi o riprodotto. La Societa' proprietaria tutela i propri disegno non potra' essere comunque utilizzato per la costruzione dell' oggetto rappresentato Proprieta' della Societa' ECOTECK s.r.l. Senza autorizzazione scitta della stessa, il presente

MODIFICARE SOLO SU CAD

(CHECKED)

CONTR.

(WEIGHT)

PESO Kg

DIS.

MATERIALE

(MATERIAL)

(DESIGNER)

DATA

(DRWG NR.)

N. DISEGNO

(DATE)

CAD DRAWNING HANDLING ON CAD SYSTEM ONLY

MODELLO

(MODEL)

TRATTAM. SUPERFICIALE

Posizione file di disegno:

X:\ECO-PROGETTI\00_STUFE\ARCHIVIO-VALIDI\MODELLI-SW\

Posizione modello 3D:

X:\ECO-PROGETTI\00_STUFE\ARCHIVIO-VALIDI\MODELLI-SW\

Ultimo salvataggio di:

pbelotti -

Data ultimo salvataggio:

mercoledì 3 dicembre 2008 10.28.48

Via Kupfer 25035 Palazzolo S/O - BRESCIA - ITALY

INTERNAL

FLUE

Airtight steel sheeting

Covering plate

YES

Union tee for condensation

45° bend, diam.80

Pic. 6

907,8

443,9

39,1

345

18,2

35,1

190

40

352

20

398,8

278,7

956,3

187,5

328

35

80

107

83

478,9

453,7

Mod.

DESCRIZIONE

Data

Dis.

Appr.

MODIFICHE

54000-00-001

-

MOD.

_

_

A1

(SCHEET)

FORMATO

LISA 2007

85.607

----

COMPLESSIVO STUFA

TOLLERANZE GENERALI PER QUOTE LINEARI, ANGOLARI, SMUSSI E

RACCORDI, CLASSE FINE UNI EN 22768-1, DOVE NON INDICATE

1:5

FCH

P.Belotti

venerdì 14 settembre 2007

SCALA

(SCALE)

DENOMINAZIONE

(DENOMINATION)

MATRICE DI PIEGA

will be legally pursued.

diritti a rigore di legge.

and must not be released to other parties without written consent any infringement

in any way utilized for the manifacture of the component of unit herein illustrated All proprietary right reserved by Society ECOTECK s.r.l. This drawing shall not be reproduced or

ne venire comunicato a terzi o riprodotto. La Societa' proprietaria tutela i propri disegno non potra' essere comunque utilizzato per la costruzione dell' oggetto rappresentato Proprieta' della Societa' ECOTECK s.r.l. Senza autorizzazione scitta della stessa, il presente

MODIFICARE SOLO SU CAD

(CHECKED)

CONTR.

(WEIGHT)

PESO Kg

DIS.

MATERIALE

(MATERIAL)

(DESIGNER)

DATA

(DRWG NR.)

N. DISEGNO

(DATE)

CAD DRAWNING HANDLING ON CAD SYSTEM ONLY

MODELLO

(MODEL)

TRATTAM. SUPERFICIALE

Posizione file di disegno:

X:\ECO-PROGETTI\00_STUFE\ARCHIVIO-VALIDI\MODELLI-SW\

Posizione modello 3D:

X:\ECO-PROGETTI\00_STUFE\ARCHIVIO-VALIDI\MODELLI-SW\

Ultimo salvataggio di:

pbelotti -

Data ultimo salvataggio:

mercoledì 3 dicembre 2008 10.28.48

Via Kupfer 25035 Palazzolo S/O - BRESCIA - ITALY

Summary of Contents for Vittoria V

Page 1: ...USE AND MAINTENANCE MANUAL Stoves with Touch Remote Vittoria V Atena V RV 120 Touch...

Page 34: ......

Page 35: ......