34

with the function mode selection switch . and

rotate the

selector to the desired operating mode.

WARNING: The operating mode selector

switch may be actuated only at a standstill.

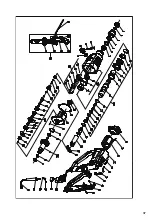

8. INSERTING/REPLACING THE KEYED

CHUCK WITH ADAPTOR (SEE E)

Inserting the keyed chuck with adaptor

To work with tools without SDS-Plus (e.g., drills

with cylindrical shafts), a keyed chuck with

adaptor(11) must be used. Insert the keyed

chuck with adaptor (11) with a twisting motion

into the tool holder until it can be heard to lock.

The adaptor locks itself. Check the locking by

pulling on the keyed chuck with adaptor

Removing the keyed chuck with adaptor

To remove the keyed chuck with adaptor (10),

pull the Locking Sleeve (1) to the rear, hold in

this position and remove the keyed chuck with

adaptor from the tool holder.

9. MOUNTING OF BIT IN THE KEYED CHUCK

WITH ADAPTOR

WARNING: Do not use tools without SDS-plus

for hammer drilling or chiseling!

Before mounting the drill bit, attaching the keyed

chuck with adaptor, insert bit between the chuck

jaws as far as it will go. Ensure drill bit is in the

center of the chuck jaws. Using the chuck key

(10) provided, there are three holes in which

the chuck key should be inserted. Tighten them

equally in turn at each of the three holes, not

just at one hole. Your drill bit is now locked in the

chuck. The bit can be removed by reversing the

above procedures.

WORKING HINTS FOR

YOUR TOOL

1. Reduce the pressure on the drill bit when

it is about to break through. This will

prevent the drill from jamming.

2. When drilling a large hole, first drill a pilot

hole using a smaller drill bit.

3. Always apply pressure to your drill bit in a

straight line, and if possible at right angles

to the workpiece.

4. Never change the operating mode whilst

the rotary hammer is running.

5. Do not apply excessive pressure to the

tool when chiseling. Expressive force

does not speed up the work.

MAINTENANCE

Remove the plug from the socket before

carrying out any adjustment, servicing or

maintenance.

There are no user serviceable parts in your

power tool.

Never use water or chemical cleaners to clean

your power tool. Wipe clean with a dry cloth.

Always store your power tool in a dry place.

Keep the motor ventilation slots clean.

Keep all working controls free of dust.

Occasionally you may see sparks through the

ventilation slots. This is normal and will not

damage your power tool.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a

hazard.

E