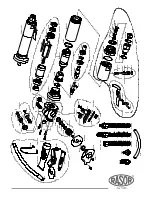

16. SPARE PARTS / EXPLODED VIEW

15. TROUBLESHOOTING

ACCESSORIES

CODE

DESCRIPTION

CODE

DESCRIPTION

P171

MALE QUICK COUPLING - 1/4" GAS

P171CPL

MALE QUICK COUPLING - 1/4" GAS

(COMPLETE)

P170

FEMALE QUICK COUPLING - 1/4" GAS

P170CPL

FEMALE QUICK COUPLING - 1/4" GAS

(COMPLETE)

P174CPL

COMPLETE COUPLING WITH THREAD -

1/4" GAS

P173

AIR PIPE Ø 8x6 mm

P169

FLEXIBLE PIPE FITTING

Ø

8 mm - 1/4"

GAS FEMALE

CODE

DESCRIPTION

CODE

DESCRIPTION

CODE

DESCRIPTION

CODE

DESCRIPTION

503EHSS

HEXAGONAL BLADE Ø 50 mm., HSS

STEEL

F 5074CPL

COMPLETE EMERY GRINDING WHEEL

UNIT

FP085

JOINT

FP86021

SILENCER SEAT O'RING

F 5032

GEAR CROWN CENTRAL PIN

F 5075

EMERY GRINDING WHEEL BUSH

FP086

SHAFT REAR BEARING

FP86022

SILENCER SEAT

F 5033

GREASER CAP

F 5076

WASHER

FP08701

SPACER

FP86025

BRONZE SILENCER-FILTER

F 5034

GREASER

F 5077

SPRING INSIDE THE SHARPENING

BUTTON, Ø 6 mm

FP088

SHAFT FRONT BEARING

FP86026

SMALL REDUCTION UNIT O'RING

F 5036

SHIM ADJUSTMENT WASHER

F 5078

SPRING INSIDE THE SHARPENING

BUTTON, Ø 9 mm

FP089

COMPENSATOR RING

FP86028

REDUCTION UNIT

F 5037

RING NUT TO FIX THE CROWN

BEARING

F 5079

SHARPENING BUTTON

FP092

O-RING

FP8612301 CONTROL HEAD

F 5038

GEAR CROWN BEARING

F 5080

SCREW FIXING THE SHARPENING

BUTTON

FP09301

COUPLING SHAFT

FP8612301CP

L

COMPLETE CONTROL HEAD

F 5040

GEAR CROWN FIXING SCREW 3,5MA

FP014

MOTOR SUPPORT

FP09301CPL COMPLETE COUPLING SHAFT

FP86127

NYLON BUSH FOR VALVE

F 5042

RING NUT FIXING THE BLADE

FP015CPL

COMPLETE GEAR CROWN

FP09401

COUPLING FLANGE

FP86130

CONNECTOR 1/4" WITH FILTER

F 5057

BLADE LOCKING DRIFT

FP05001CPL COMPLETE MOTOR

FP095

HANDLE FOR HOOK

FP86146

COMPLETE CONTROL LEVER

F 5059

BLADE DISASSEMBLY KEY

FP074

REAR FLANGE

FP096

COMPENSATION RING NUT

FRNF503

SET OF ACCESSORIES FP503

F 5065

SCREW FIXING THE FOOT

FP075

REAR FLANGE PLUG

FP86010

PISTON GUIDE

P001

WORM SCREW

F 5066

PLATE LOCKING THE THREADS

FASTENING SCREW

FP076

REAR FLANGE BEARING

FP86011

PISTON GUIDE O' RING

P002

SPRING PIN

F 5067

PLATE LOCKING THE THREADS

FP077

POSITION PIN

FP86012

PISTON GUIDE O' RING

P003

ROLL BEARING

F 5068

WIDIA COUNTERBLADE WITH SPRING

FP078

BUCKETS

FP86013

PISTON

P005

SUPPORT FIXING SCREW 4MA

F 5069

SCREW FIXING THE COUNTERBLADE

FP079

CYLINDER

FP86013CPL COMPLETE PISTON WITH GUIDE

P029

RUBBER HOSE

F 5070

STEEL FOOT

FP080

ROTOR

FP86014

STOP RING

T102906

LEVER AND RATCHET FIXING PIN

F 5070CPL COMPLETE FOOT

FP080CPL

COMPLETE TURBINE

FP86017

VALVE

T102909

RATCHET FOR LEVER

F 5071

BLADE PROTECTION GUARD

FP081

FRONT FLANGE BEARING

FP86018

VALVE O' RING

T102910

RATCHET SPRING

F 5071/1

SCREW FIXING THE BLADE

PROTECTION GUARD

FP082

FRONT FLANGE

FP86019

STEEL BALL

T107900

LUBRICATING GREASER

F 5074

PLATE WITH EMERY

FP08301

MOTOR CASE

FP86020

CONICAL SPRING

T107902

LUBRICATING OIL (15 ml)

à

SOLUTION

Check the counterblade integrity

Check the kind of fabric

Sharpen the blade

Check the fabric thickness

Check the compatibility between blade and fabric

Make sure that the turbine turns correctly

Reduce the feeding speed

Carry out the lubrication

Disassemble the blade and remove the material residues

Check the silencer

Check the wear of the gear pair

Check the air circuit integrity

Set working pressure at 6 bar

The scissors start slowly or work intermittently

6

PROBLEM

The pneumatic scissors are noisy

The fabric is not cut or it gets stuck between the

blade and the counterblade

EN

28