EN

3

1. GENERAL SAFETY RULES

This manual is an integral part of cutting unit FP120M and must be carefully read

before using it since it gives important indications with regards to its safe

installation, use and maintenance. Keep it with care.

Before using cutting unit FP120M, read carefully the following general safety

rules.

•

PACKAGING.

After taking off the packaging make sure that the cutting unit is intact. In case of

doubt do not use it and contact an authorized service centre. Do not leave

pieces of packaging (plastic bags, foam polystyrene, boxes, etc.) within the

reach of children or disabled persons since they are potential sources of danger.

•

AVOID DANGEROUS ENVIRONMENTS.

•

KEEP CHILDREN AWAY.

Unauthorized persons, in particular children, must be kept away from the working

area.

•

KEEP THE WORKING AREA ALWAYS IN ORDER.

The workplace must always be kept in order and well lightened;

•

ALWAYS USE CUTTING UNITS FP120M PROPERLY.

Use the cutting units only to carry out the works they have been designed for;

do not use them improperly.

•

OBSERVE THE USE OF THE TOOL.

Do not cut excessively thick materials and always check blade conditions.

•

AVOID ACCIDENTAL STARTINGS.

Before connecting cutting unit FP120M, make sure that everything is installed

properly.

•

CLOTHING.

Do not use large clothes or accessories that might get stuck in the moving parts.

•

GOGGLES AND PROTECTIVE METAL MESH GLOVES.

Always use goggles, protective metal mesh gloves suggested by Rasor

®

during

use and maintenance operations (according to UNI EN 388:2017 standard).

•

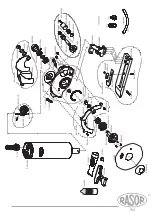

SPARE PARTS.

During maintenance and replacement operations use only original spare parts.

Blade maintenance must be only performed by Rasor

®

technicians.

•

INSTALLATION.

Any installation that is not in conformity with these specifications could jeopardize

your safety and cancels the warranty.