5

INST

ALLA

TION/PLUMBING

PLUMBING

WARNING: HAZARD OF FLOODING

Toilets mounted at or below the waterline, at greatest angle of heel, and connected to a Seacock/

Thru Hull Fitting(s) MUST have VENTED LOOPS installed in toilet discharge plumbing

and between raw water intake pump and toilet bowl.

Install vented loops per manufacturer’s instructions. Double clamp all below-waterline

connections.

IMPORTANT

• Fittings and 90° bends should be kept to a minimum.

• In-Line Strainer (Raritan part # 163000) may be installed. This will help prevent clogs.

• Discharging untreated sewage is forbidden in all U. S. waters within the three-mile limit.

• Thru-hull fittings and seacocks must be installed where they are easily accessible.

• Use only quality reinforced hoses such as Raritan Saniflex (SFH)

• Secure all hoses properly.

1. Route discharge hose above discharge

outlet with a vented loop. This will

enable the toilet to discharge more

efficiently and will help to prevent

backflow.

2. An In-Line Strainer (#163000)

is recommended. This will help

minimize odors and help prevent

clogging.

3. Intake and discharge thru-hull fittings

should be located far enough apart to

prevent discharge water from being

drawn through the intake.

4. The optional Raritan Knocks Out

Odors Kit (#KO2) enables the use

of Cleans Potties (#1PCP32). Raritan

Cleans Potties deodorizes the bowl

and lubricates internal parts.

5. Flush and check for leaks.

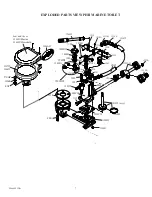

PHII Marine Toilet

Vent Outside

Hull or Deck

Waterline

Waterline

Vented

Loop

In-Line

Strainer

Intake Thru-Hull

and Seacock

Discharge Thru-

Hull and Seacock

FIG 4

Sanitation Device

*Drawing not to scale

Above Waterline Installation

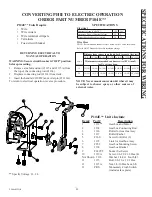

FIG 5

*Drawing not to scale

PHII Marine

Toilet

Waterline

Waterline

Discharge Thru-

Hull and Seacock

Intake

Thru-Hull and

Seacock

Vented

Loops

Sanitation

Device

Holding Tank

Deck Pumpout

Y Valve

In-Line

Strainer

Below Waterline Installation

L584v0222jlc