4

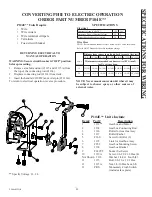

SPECIFICA

TIONS/INST

ALLA

TION

Tools Required

• 5/16" nut driver

• Wrench or screwdriver

• Bit for drilling mounting surface

• Hose cutters

• Tape measure

Additional Parts Required

• Four stainless steel mounting bolts or lag

screws (minimum 1/4" [6mm]) and washers

• 1 1/2" I.D. discharge hose

• 3/4" I.D. reinforced intake hose

• Hose clamps (two for each connection below

waterline)

Mounting Toilet

Mounting surface must be flat and solid.

1. Install seat on toilet.

2. Place toilet where it will be located.

Make sure there is room to route hoses.

Make sure seat will open properly.

3. Mark location of toilet base mounting holes on

mounting surface.

4. Drill holes for toilet mounting bolts/screws.

5. Secure toilet to surface.

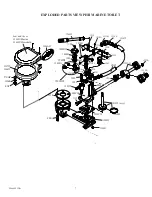

RARITAN PHII MARINE TOILET FRONT VIEW, SIDE VIEW AND FOOTPRINT

NA

(SEE B)

HOUSEHOLD

BOWL TYPE

MARINE

14 1/2

(368)

11 1/2

(292)

20

(508)

inch

(mm)

10

(254)

C

B

A

17

(432)

E

D

14 1/4

(362)

18 1/4

(464)

18

(458)

17 3/8

(442)

D

13 1/2

(343)

E

A

B

C

2

(51)

9 1/4"

23.6cm

4 1/2"

11.4cm

9"

22.9cm

4"

10.2cm

4"

10.2cm

WALL AT REAR OF TOILET

DISCHARGE

HOSE HOLE

LONGITUDINAL

CENTERLINE

OF TOILET

INLET

HOSE HOLE

>

>

>

>

>

>

3 1/2"

8.9cm

>

5"

12.7cm

10"

25.4cm

(8 1/2"

21.6cm)

>

>

L584v0222jlc