13

ArtNo.302-0010 -

Activating the key lock 3

ArtNo.302-0008 -

Activating the key lock 1

ArtNo.302-0009 - Activating

the key lock 2

Fig.2-39

Fig.2-40

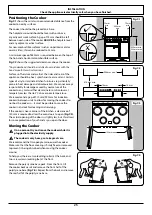

ArtNo.302-0011 - 6BC

Deactivating the key lock 1

Fig.2-41

Fig.2-42

ArtNo.302-0012 -

Deactivating the key lock 2

Fig.2-43

AUTO is showing, you want to reset to manual cooking

To return to manual cooking from any automatic setting,

the

‘cook period’

must be cancelled. Press and hold the [

]

button and then press the [ –] button until the display reads

(

0.00

).

Press the [

] button to return to manual cooking.

Key Lock

Activating the key lock will lock the left-hand oven and it will

not come on.

The right-hand oven can be operated as usual.

To activate the key lock

Make sure that the clock is in manual mode and cancel

any active programs.

Hold the Minute Minder [

] and Cook period [

] buttons.

When ‘On’ appears on the display

(Fig.2-39)

press the [+]

button once. The key symbol [

] and ‘OF’ will now show on the

display

(Fig.2-40)

. Release the buttons.

The left-hand oven is now locked, as confirmed by the display

showing the time of day alongside the key symbol

(Fig.2-41)

.

To turn off the key lock

Hold the Minute Minder [

] and Cook period [

] buttons.

When ‘OF’ appears on the display

(Fig.2-42)

press the [+]

button once. The key symbol [

] will go out and ‘On’ will show

on the display

(Fig.2-43)

. Release the buttons.

After a few seconds the display will revert to show the time of

day.

The oven can now be used normally.

Summary of Contents for 90 Induction

Page 1: ...90 Induction Britain s No 1 Range Cooker USER GUIDE INSTALLATION INSTRUCTIONS...

Page 4: ...ii...

Page 38: ...34 Notes...