10

3.

≤

Install a conical washer and apply thread

lock to 3 flat head bolts from kit 860073.

Insert a bolt through the crossmember, each

spacer, and into the frame. See figure 12.

4.

≤

Repeat steps 2 and 3 for the other side of

the crossmember. Tighten all bolts to 45 FT-

LBS.

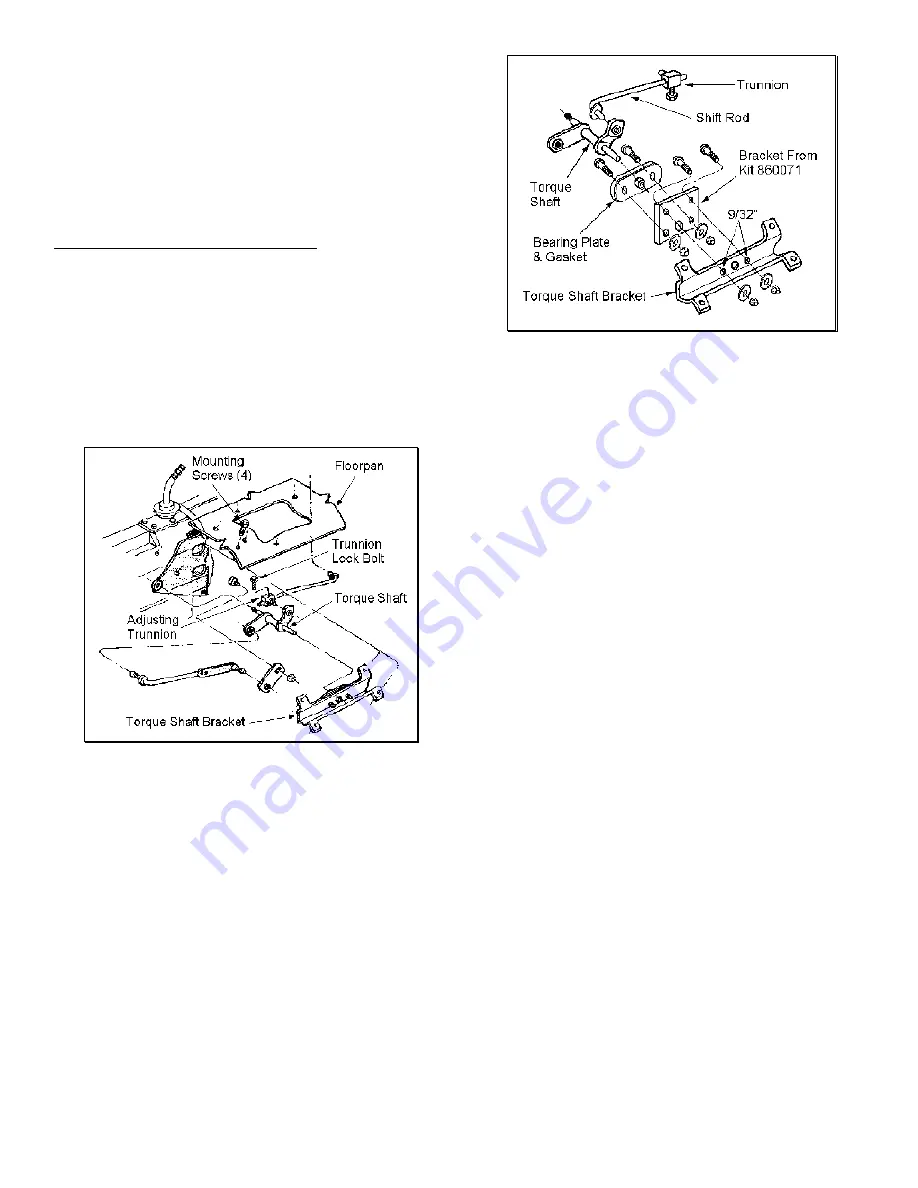

Linkage Relocation & Adjustment

1.

≤

Pull back carpet/mat to gain access to

torque shaft bracket mounting screws. If

necessary, loosen the screws attaching the

console to the floor panel.

2.

≤

Remove the four screws that attach the

torque shaft bracket to the floor pan. See

figure 13.

Figure 13

3.

≤

Slide the torque shaft bracket off the torque

shaft, and remove the bearing plate & gasket.

Drill out the two threaded holes in the torque

shaft bracket to 9/32".

4.

≤

Attach the shift relocating bracket (from kit

860071) to the torque shaft bracket as shown

in figure 14. Use the hardware from kit

860071.

5.

≤

Attach the bearing plate, with gasket, to the

shift relocating bracket. See figure 14.

Figure 14

6.

≤

Insert the torque shaft into the bearing plate

and reinstall the torque shaft bracket to the

floor pan. Verify that the torque shaft is level

and the shifting linkage moves without

restriction. If necessary, file the end of the

shift rod to provide adequate clearance.

7.

≤

Shift transfer case into 4L position and

loosen lock bolt on adjusting trunnion.

Note: Be sure shift rod slides freely in

trunnion.