A-A

MO

T

O

R C

O

NT

RO

L VAL

VE

D

E

T

A

IL

140

,5

412

,7

16

.2

5

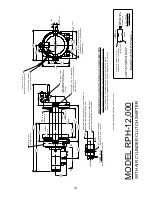

WITH AIR CYLINDER CLUTCH SHIFTER

MODEL RPH-12,000

VI

E

W

WI

NC

H

96,

3

3.7

9

A

9.12

R

E

CEIVE 1

2

V D

C

WH

EN

PTO

IS

EN

GAG

E

D

.

A

T

T

A

CH

TO P

T

O IND

ICATOR SW

IT

C

H

TO

AT

TAC

H

TO GR

OUND

(16

GA.

WIR

E

S

U

PPL

IED

BY

C

U

STOM

ER

)

NOTE:

LI

GHT

SHOU

LD BE

"O

N

" WH

EN

CL

U

T

C

H

IS

E

N

GA

GE

D A

N

D "

O

FF"

W

H

E

N

C

LUTC

H

IS

DISE

NGA

G

E

D

.

TR

UE PO

SI

T

IO

N

. REC

O

MM

END

E

D MO

UNT

IN

G

HO

LE

D

IA

M

E

T

ER

IS

.5

3"

(

1

3,

5

MM

).

*N

OTE: THESE HO

LE LOC

A

T

IONS M

U

ST BE HEL

D

WI

THI

N

±.

03

" (

0,8

MM

) O

F

4.6

2

11

7,3

.500

-13

U

NC

X .6

2" (

1

5,

7

M

M

)

DEEP

T

A

PPED HO

LE (TYP.

4

P

L

A

C

E

S

EAC

H

** CAU

T

IO

N: PR

ESSUR

E

MUST

N

O

T

EXC

EE

D

1

5

0

PSI

.

R

O

TATION

VIEWED

FR

O

M

MOTO

R

END

PR

ES

SUR

E

IN

GIVES CL

OC

KWIS

E

D

R

U

M

PR

ESSU

RE

IN

GI

VES

CO

UN

T

E

R-

CL

OC

KWIS

E D

R

U

M

R

O

TATION

VIEW

ED

FROM

MOTO

R

END

1.7

5

.87

5

-1

4 SAE S

T

R

A

IG

H

T

TH

R

EAD

O-

RIN

G

PORT (

T

YP.

2

P

L

A

C

ES)

.8

8

22

,4

44,5

*

4.

8

8

12

4,0

A

5.5

3

12.2

5

31

1

,2

9.7

5

24

7

,7

10

0

,0

3.

9

4

BA

RR

EL

DI

A.

DR

UM

SI

DE O

F

WI

NC

H

)

PRESSU

RE

LI

NE TO DI

SEN

G

A

GE

(C

ONN

E

CT 80

T

O

150

PSI

*

*

C

LUT

CH)

.125-

2

7N

PT PO

R

T

23

1,6

SCHEM

A

TIC

ELECTRICAL

IS

EN

GAG

E

D)

(ON W

H

E

N

CL

UTCH

IN

DI

C

A

TO

R LI

G

H

T

12V BATTER

Y

+

_

SWI

T

CH

CONN

E

C

TO

R

BU

TT

(T

Y

P

.)

(TYP.

)

2.

25

57

,2

T

APPED

HOL

E

(TYP.

4 PL

AC

E

S

E

A

C

H

.50

0

-1

3UN

C

X

.75"

(1

9,1

M

M

) DEE

P

*

11

5

,8

END

BE

ARIN

G

)

4.56

23

1

,6

9.

1

2

TUL

SA OK

*

(TYP.

)

28

,4

1.

1

2

1.1

2

28

,4

*

2.2

1

56,

1

751

,3

FLANGE

29

.5

8

228

,6

9.

0

0

DI

A

.

STAT

IC

L

O

A

D

HO

LD

IN

G BR

AKE

6.12

15

5

,4

.5

0

CABLE H

O

LE

12

,7

DIA

.

ATTACH TO GROUND

(S

EE

EL

ECTR

ICAL S

CHEMATIC

)

3.81 96,8

ATTACH TO 1

2

V

DC

(+)

(S

EE ELE

C

TRICA

L

SCH

E

M

A

TIC)

(T

Y

P

.)

R

A

M

S

E

Y

WIN

CH CO

L

E

H

W

*C

D

T

L

I

E

N

*

5.0

5

128,4

256

,8

C

56

,1

2.

2

1

T

U

G

E

H

N

A

G

10.1

1

14

,2

.56

*

DIMENSIONS SHOWN

ARE

INCHES OVER MILLIMETERS

WIN

C

H

M

O

UN

TIN

G

C

APSC

RE

WS M

U

ST M

EET O

R

EX

CE

ED S

AE G

R

A

D

E 5

S

PECI

F

IC

A

T

IO

N

14

Summary of Contents for RPH 12,000

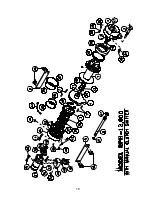

Page 15: ...MODEL RPH 12000 WITH MANUAL CLUTCH SHIFTER 13 ...

Page 17: ...15 NOTES ...

Page 18: ...16 ...

Page 20: ...18 ...

Page 22: ...20 ...