Lubricate the outside truck block idler and drive gears with grease. Use the

diagram shown in Figure 6 below as a guide and add grease to the points marked.

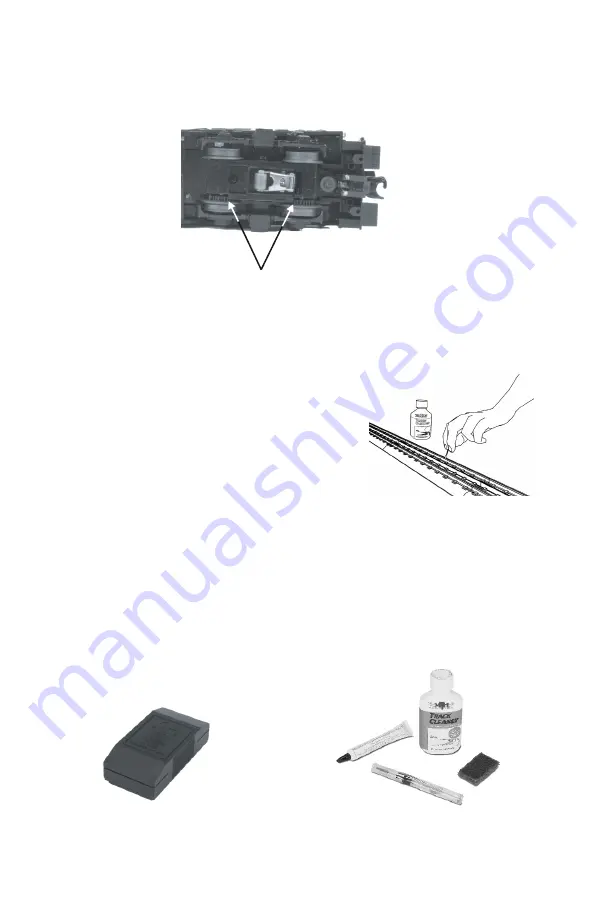

Cleaning The Wheels, Tires, and Track

Periodically check the locomotive wheels and pickups

for dirt and buildup, which can cause poor electrical

contact and traction and prematurely wear out the

neoprene traction tires. Wheels and tires can be

cleaned using denatured (not rubbing) alcohol applied

with a cotton swab.

To clean the track, use RailKing Track Cleaning Fluid

found in Maintenance Kit (30-50010) or denatured (not rubbing) alcohol and a clean

rag. Unplug the transformer and wipe the rails of the track, turning the rag frequently

to ensure that you are using clean cloth on the rails. Thereafter, keep an eye on the

track and clean it when it gets dirty to ensure good electrical contact and to lengthen

the life of the tires.

Clean any type of track with this heavy-duty track cleaning block (

. Durably

constructed from ABS plastic, the block includes a built-in cleaning pad. For really

stuborn track, you can insert sandpaper into the

block in just a few quick steps.

40-1099)

RKS GP7 & GP9 Diesel Engine with PS-2

12

Figure 6. Greasing The Idler Gears

Track Cleaning Block (40-1099)

Maintenance Kit (30-50010)

Grease Idler Gear (G)