Page 3

Leaving the RTM300 sensor connected whilst conducting a 500v insulation

(Megger) test will damage the sensor’s internal electrical components

rendering it unusable and invalidating any existing warranty.

6

INSTALLATION

CAUTION Ensure that all proper safety precautions are taken. Observe all

National and Customer codes of conduct and procedures whilst working on

any street furniture. Provisions should be made to ensure safe operation of

the crossing/junction at all times.

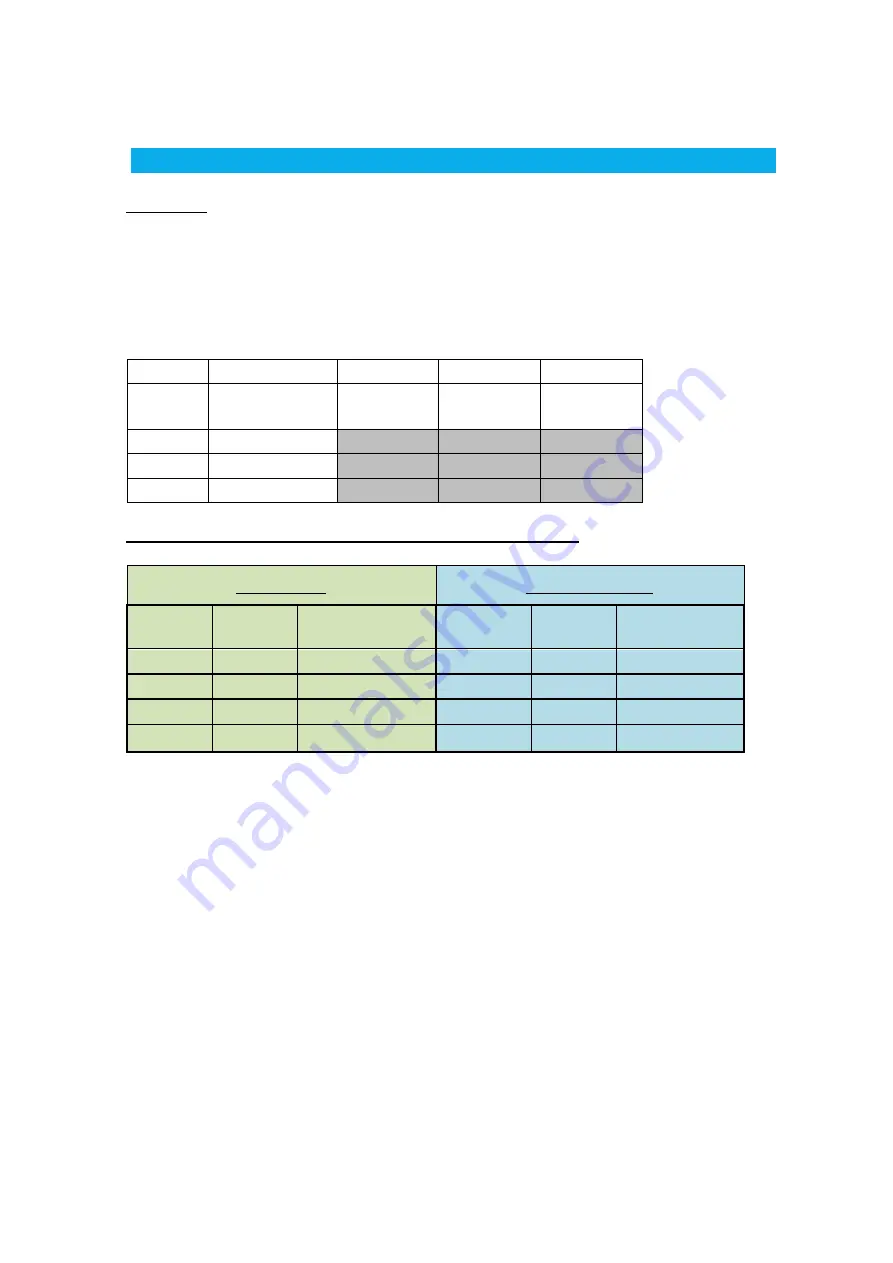

Confirm the operational modes required and set the front panel switches and

jumpers J1-4 of the RTM500 interface card accordingly.

Jumper Function

Fitted

Not Fitted

Notes

1

Output mode

Low

power

Fail safe

(TR2512)

Issue 3

and below

2

Not used

3

Not used

4

Not used

RTM500 Sensitivity & Presence Time Switch Settings

Sensitivity

Presence Time

S1

S2

P1

P2

0

0

LOW

0

0

CH OFF

1

0

MED LOW

1

0

3s

0

1

MED HIGH

0

1

4min

1

1

HIGH

1

1

35min

NOTE: This equipment is fitted with overvoltage protection to minimise the

disruption that may be caused by induced voltages from lightning or other

environmental effects.

6.1 INSTALLATION OF THE RTM300 SENSOR

6.1.1 The installation of the RTM300 sensor presumes that a suitable duct has

been installed, has sufficient capacity and is accessible. Where more than

one sensor is to be installed in the same duct, install the furthest sensor first

and work progressively to the nearest sensor.

Further information on the installation of ducts can be found in Appendix 3.

6.1.2 Attach a sufficiently long and suitable (e.g polypropylene) draw cord to the

attachment point on the sensor. Using the site plans or by measurement

along the kerb at 90° and at 45° (see figure 1 below) find the distance to the

white line. Half of this is the mid lane distance. Add on the set back of the

duct end in the pit from the kerb line to get the distance that the sensor has to

be pushed out. Measure off this distance on the draw cord and mark it using

suitable tape.