Radijator Inženjering d.o.o, 36000 Kraljevo, Živojina Lazića

- Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150, http://www.radijator.rs

e-mail: [email protected]

49

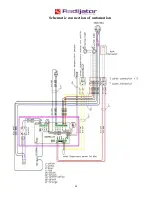

Figure 12. Positions of Flap in OPEN and CLOSE modes and look of TURBULATORS

Figure 13. View of the positions of flap on the flue gas chute

!

When working with coal dust, the boiler must not be added with fuel during its

operation. Adding of fuel is done only after when the previous fuel has burned out. During the

operationt he boiler should be monitored once within every 5-6 hours.

!

Opening the upper door for firing during the operation should be performed as

rarely as possible, only for an examination of the boiler.The door must then be opened very

slowly and cautiously, at first only slightly, keeping it i that position for ten seconds and then

open it fully. It is very dangerous to open the upper door in the situation when the fan is not

working.Then the created combustion gases exit through the door, and in contact with oxygen

burn turbulently. In these cases it could result in heavy and light injuries, or putting the boiler

room on fire. That is why the door is opened as described above, and preferably, as soon as

after fan’s function, the so

-called "ventilation".