910198 – Tie Tamper

Phone: (262) 637-9681

11.2019 Rev 1.1

Page

8

of

21

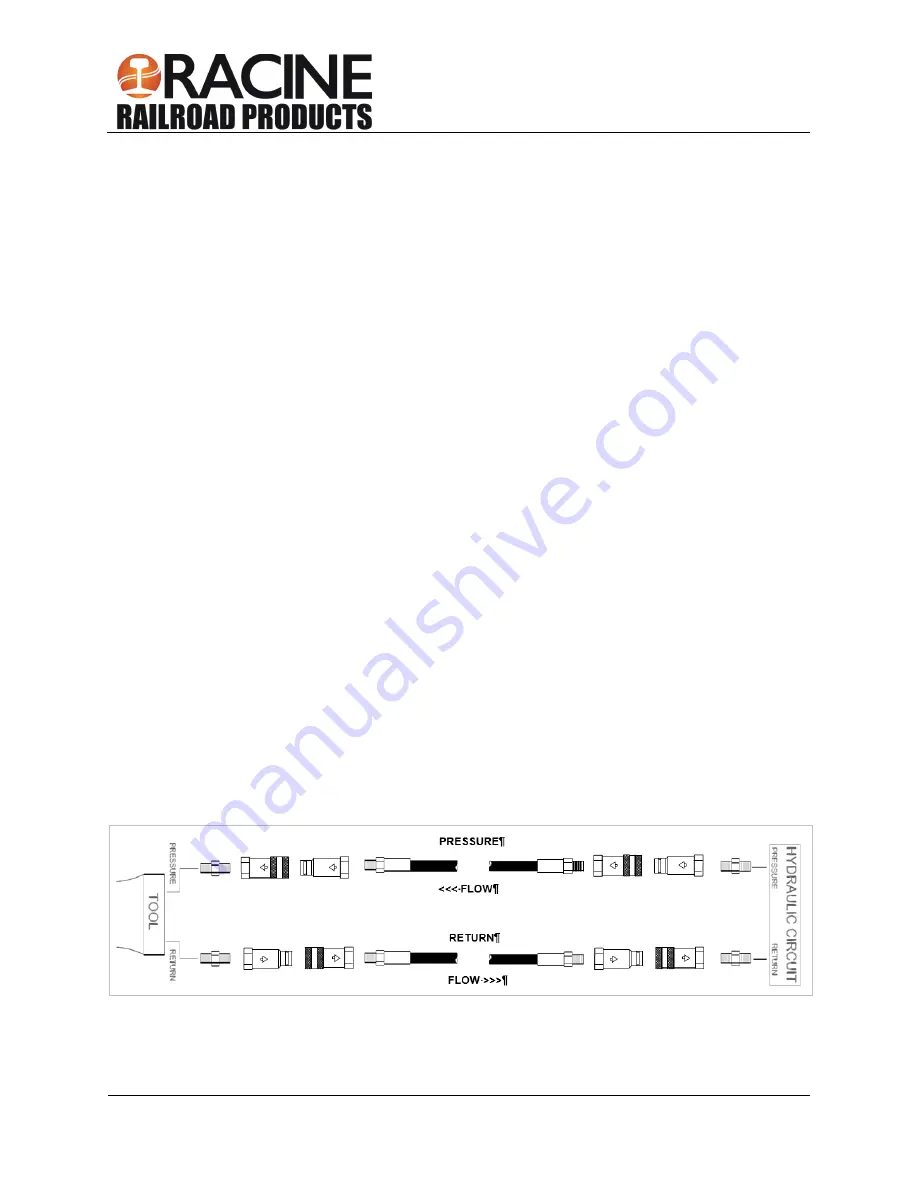

Hose Requirements

It is not often necessary or advisable to use long hoses. All hoses must have an oil resistant inner surface

and an abrasion resistant outer surface. Each hose must have male pipe ends for most application.

Longer hoses can be used when necessary but can affect the operation of the tool due to resistance in

the hose.

If small diameter or long hoses are used, or if restrictive fittings are connected to the supply and return

ports, the pressure required to push the fluid through the system and back to the tank will be higher. This

will reduce tool power.

Important:

Oil should always flow from the male coupler through the female coupler.

Note:

The pressure increases in uncoupled hoses left in the sun. This may make them difficult to

connect. When possible after use, connect the free ends of the operating hoses together.

Hose Types

Hydraulic hose types authorized for use with the Tie Tamper are:

1.

Labeled and certified non-conductive

.

•

This is the only hose authorized for use near electrical conductors.

•

Constructed of thermoplastic or synthetic rubber inner tube, synthetic fiber braid reinforcement,

and weather resistant thermoplastic or synthetic rubber cover.

2.

Wire braided

(conductive)

•

This hose is conductive and must

never

be used near electrical conductors.

•

Constructed of synthetic rubber inner tube, single or double wire braid reinforcement, and

weather resistant synthetic rubber cover

3.

Fiber braided

(not certified or labeled non-conductive)

•

This hose is conductive and must

never

be used near electrical conductors.

•

Constructed of thermoplastic or synthetic rubber inner tube, synthetic fiber braid reinforcement,

and weather resistant thermoplastic or synthetic rubber cover.

The rated working pressure of the hydraulic hose must be at least 175 bar (2500 psi).

All hydraulic hose must meet or exceed specifications as set forth by SAE J517.

Typical Hose Connections