910198 – Tie Tamper

Phone: (262) 637-9681

11.2019 Rev 1.1

Page

11

of

21

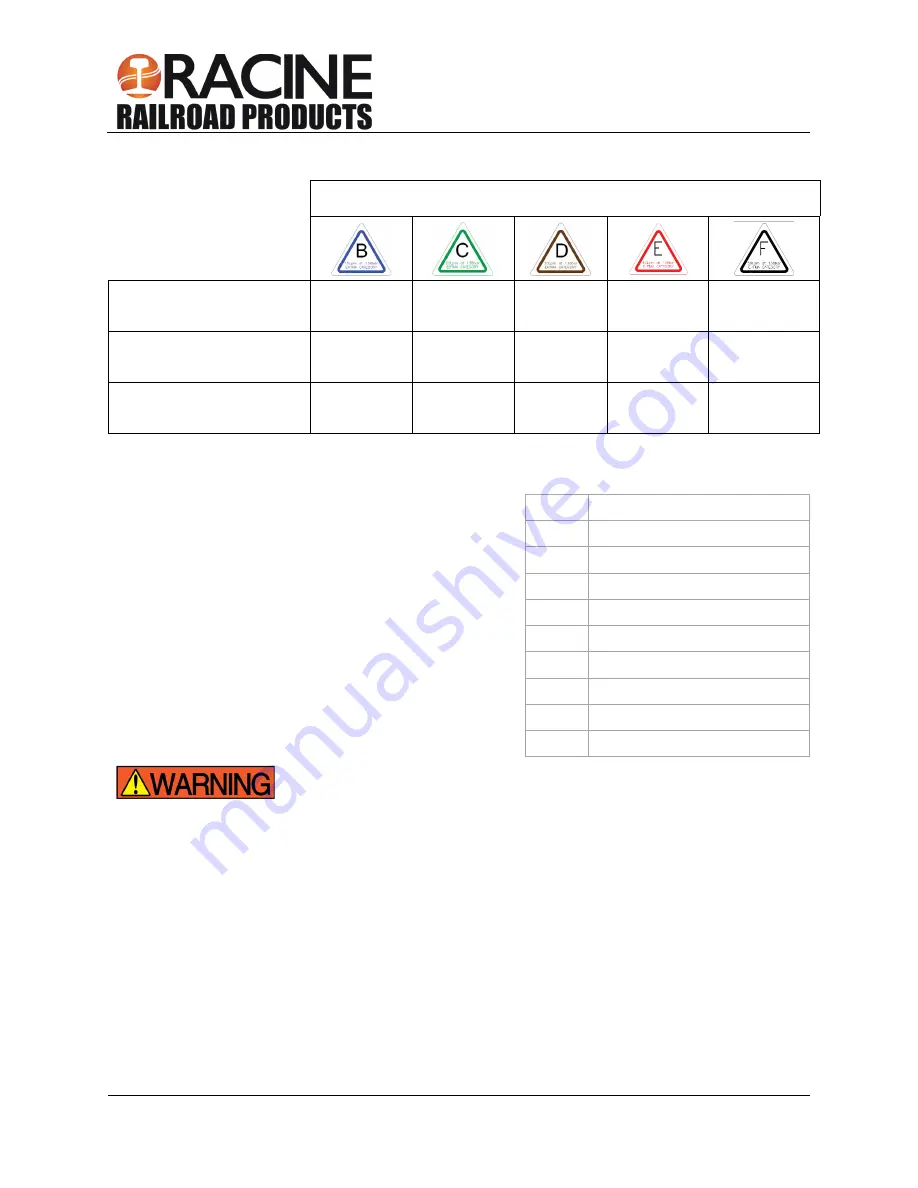

EHTMA Hydraulic System Requirements

Classification

Flow Range

3.5-4.3 gpm

3.5-4.3 gpm

4.7-5.8 gpm

(18-22 lpm)

7.1-8.7 gpm

(27-33 lpm)

9.5-11.6 gpm

(36-44 lpm)

11.8-14.5 gpm

(45-55 lpm)

Nominal Operating Pressure

1870 psi

(129 bar)

1500 psi

(103 bar)

1500 psi

(103 bar)

1500 psi

(103 bar)

1500 psi

(103 bar)

System relief valve setting

at the power supply outlet.

2495 psi

(172 bar)

2000 psi

(138 bar)

2000 psi

(138 bar)

2000 psi

(138 bar)

2000 psi

(138 bar)

Hydraulic Fluid Recommendation

Inspect hoses for cuts, crushing, leaks, or abrasion, which

may be a safety hazard or reduce fluid flows.

The following fluids work well over a wide temperature

range at startup, allow moisture to settle out, and resist

biological growth likely in cool operating hydraulic circuits.

Others that meet or exceeds the specifications of these

fluids may also be used.

Type

Hydraulic fluid

Chevron Clarity AW 15032

Exxon

Univis J 32

Mobil

D.T.E. 13M

Gulf

Harmony AW-HVI-150-32

Shell

Tellus T 32

Texaco Rando HDZ 32

Union

Unax AW-WR-32

Amsoil AWH 15032

Sunvis

Low Pour H/032-product code 19300

Do not inspect or clean the tool while the hydraulic power source

is connected. Accidental engagement of the tool can cause

serious injury.

Always connect hoses to the tool hose couplers before energizing

the hydraulic power source. Be sure all hose connections are tight

and are in good condition.

Do not operate the tool at oil temperatures above 140°F/60°C.

Operation at higher temperatures can cause higher than normal

temperatures at the tool which can result in operator discomfort.

When working near electrical conductors, always assume that all

conductors are energized and that insulation, clothing and hoses

can conduct electricity. Use hose labeled and certified as non-

conductive.