Page 3

05103V-90(J)

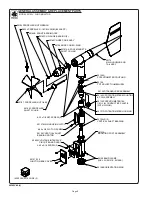

c) Loosen two set screws at base of transducer assembly

and remove assembly from vertical shaft.

d) Unscrew potentiometer housing from potentiometer

mounting & coil assembly.

e) Push potentiometer out of potentiometer mounting & coil

assembly by applying firm but gentle pressure on

potentiometer shaft. Make sure that the shaft o-ring

comes out with the potentiometer. If not, then gently

push it out from the top of the coil assembly.

4. INSTALL NEW POTENTIOMETER

a) Push new potentiometer into potentiometer mounting &

coil assembly making sure o-ring is on shaft.

b) Feed potentiometer and coil wires through hole in bottom

of potentiometer housing.

c) Screw potentiometer housing onto potentiometer

mounting & coil assembly.

d) Gently pull transducer wires through bottom of

potentiometer housing to take up any slack. Apply a

small amount of silicone sealant around hole.

e) Install transducer assembly on vertical shaft allowing

0.5 mm (0.020") clearance from vertical bearing.

Tighten set screws* at bottom of transducer assembly.

f) Place potentiometer adjust thumbwheel on potentiometer

shaft and tighten set screw*.

g) Place potentiometer coupling on potentiometer

adjust thumbwheel. Do Not tighten set screw yet.

5. RECONNECT TRANSDUCER WIRES

a) Using needle-nose pliers or a paper clip bent to form a small

hook, gently pull transducer wires through hole in junction

box.

b) Solder wires to circuit board according to wiring diagram.

Observe color code.

c) Secure circuit board in junction box using two screws

removed in step 2b. Do not overtighten.

6. REPLACE MAIN HOUSING

a) Place main housing over vertical shaft bearing rotor. Be

careful to align indexing key and channel in these two

assemblies.

b) Place main housing over vertical shaft bearing rotor until

potentiometer coupling is near top of main housing.

c) Turn potentiometer adjust thumbwheel until potentiometer

coupling is oriented to engage ridge in top of main housing.

Set screw on potentiometer coupling should be facing the

front opening.

d) With potentiometer coupling properly oriented, continue

pushing main housing onto vertical shaft bearing rotor until

main housing latch locks into position with a “click”.

7. ALIGN VANE

a) Connect excitation voltage and signal conditioning

electronics to terminal strip according to wiring diagram.

b) With mounting post held in position so junction box is facing

due south, orient vane to a known angular reference. Details

appear in CALIBRATION section.

c) Reach in through front of main housing and turn

potentiometer adjust thumbwheel until signal conditioning

system indicates proper value.

d) Tighten set screw* on potentiometer coupling.

8. REPLACE NOSE CONE

a) Screw nose cone into main housing until o-ring seal is

seated. Be certain threads are properly engaged to avoid

cross-threading.

FLANGE BEARING REPLACEMENT

If anemometer bearings become noisy or wind speed threshold

increases above an acceptable level, bearings may need

replacement. Check anemometer bearing condition using a Model

18310 Propeller Torque Disc. If necessary, bearings are replaced

as follows.

1. REMOVE OLD BEARINGS

a) Unscrew nose cone. Set o-ring aside for later use.

b) Loosen set screw on magnet shaft collar and remove

magnet.

c) Slide propeller shaft out of nose cone assembly.

d) Remove front bearing cap which covers front bearing.

e) Remove both front and rear bearings from nose cone

assembly. Insert edge of a pocket knife under bearing flange

and lift it out.

2. INSTALL NEW BEARINGS

a) Insert new front and rear bearings into nose cone.

b) Replace front bearing cap.

c) Carefully slide propeller shaft thru bearings.

d) Place magnet on propeller shaft allowing 0.5 mm (0.020")

clearance from rear bearing.

e) Tighten set screw* on magnet shaft collar.

f) Screw nose cone into main housing until o-ring seal is

seated. Be certain threads are properly engaged to avoid

cross-threading.

VERTICAL SHAFT BEARING REPLACEMENT

Vertical shaft bearings are much larger than the anemometer

bearings. Ordinarily, these bearings will require replacement less

frequently than anemometer bearings. Check bearing condition

using a Model 18331 Vane Torque Gauge.

Since this procedure is similar to POTENTIOMETER

REPLACEMENT, only the major steps are listed here.

1. REMOVE MAIN HOUSING.

2. UNSOLDER TRANSDUCER WIRES AND REMOVE

TRANSDUCER ASSEMBLY. Loosen set screws at base of

transducer assembly and remove entire assembly from vertical

shaft.

3. REMOVE VERTICAL SHAFT BEARING ROTOR by sliding it

upward off vertical shaft.

4. REMOVE OLD VERTICAL BEARINGS AND INSTALL NEW

BEARINGS. When inserting new bearings, be careful not to

apply pressure to bearing shields.

5. REPLACE VERTICAL SHAFT BEARING ROTOR.

6. REPLACE TRANSDUCER & RECONNECT WIRES.

7. REPLACE MAIN HOUSING.

8. ALIGN VANE.

9. REPLACE NOSE CONE.

*Max set screw torque 80 oz-in