Section VIII - Troubleshooting

Symptom/Probable Causes:

Corrective Action:

Quincy Compressor

®

- QSB/T

™

65

R

EPLACE

OR

REPAIR

GUARD

.

U

SE

CORRECT

BELT

TO

SHEAVE

COMBINATION

.

R

ETENSION

BELTS

.

R

EALIGN

AND

RETENSION

DRIVE

.

R

EPLACE

SHEAVES

.

R

EPLACE

WITH

CORRECT

BELT

SET

.

U

SE

CORRECT

BELT

TO

SHEAVE

COMBINATION

.

R

EPLACE

SHEAVES

.

U

SE

CORRECT

BELT

TO

SHEAVE

COMBINATION

.

R

EPLACE

SHEAVES

.

C

LEAN

SHEAVES

AND

IMPROVE

SHIELDING

.

U

SE

CORRECT

BELT

TO

SHEAVE

COMBINATION

.

R

ETENSION

BELTS

.

D

O

NOT

COIL

,

KINK

OR

BEND

BELTS

. A

VOID

HEAT

AND

DIRECT

SUNLIGHT

.

R

ETENSION

BELTS

.

R

EPLACE

SHEAVES

.

C

HECK

FOR

CENTER

DISTANCE

CHANGES

.

I

MPROVE

VENTILATION

TO

DRIVE

.

D

O

NOT

USE

BELT

DRESSING

. E

LIMINATE

SOURCE

OF

CONTAMINATION

.

Severe or Abnormal Belt Wear:

W

EAR

ON

TOP

OF

BELT

:

R

UBBING

AGAINST

GUARD

W

EAR

ON

TOP

CORNERS

OF

BELT

:

I

NCORRECT

BELT

TO

SHEAVE

FIT

(

BELT

TOO

SMALL

FOR

GROOVE

)

W

EAR

ON

SIDEWALLS

OF

BELT

:

B

ELT

SLIP

M

ISALIGNMENT

W

ORN

SHEAVES

I

NCORRECT

BELTS

W

EAR

ON

BOTTOM

CORNER

OF

BELT

:

I

NCORRECT

BELT

TO

SHEAVE

FIT

(

BELT

TOO

SMALL

FOR

GROOVE

)

W

ORN

SHEAVES

W

EAR

ON

BOTTOM

SURFACE

OF

BELT

:

B

ELT

BOTTOMING

ON

SHEAVE

GROOVE

W

ORN

SHEAVES

D

EBRIS

IN

SHEAVES

U

NDERCORD

CRACKING

:

S

HEAVE

DIAMETER

TOO

SMALL

B

ELT

SLIP

I

MPROPER

BELT

STORAGE

U

NDERCORD

OR

SIDEWALL

HARDENING

:

B

ELT

SLIP

W

ORN

SHEAVES

S

HAFT

MOVEMENT

B

ELT

SURFACE

HARD

OR

STIFF

:

H

OT

DRIVE

ENVIRONMENT

B

ELT

SURFACE

FLAKY

,

STICKING

OR

SWOLLEN

:

C

HEMICAL

CONTAMINATION

Summary of Contents for QSB Series

Page 2: ......

Page 9: ...Section I General Quincy Compressor QSB T 5 MODEL IDENTIFICATION...

Page 21: ...Quincy Compressor QSB T 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 27: ...Quincy Compressor QSB T 23 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 71: ...Quincy Compressor QSB T 67 THIS PAGE INTENTIONALLY LEFT BLANK...

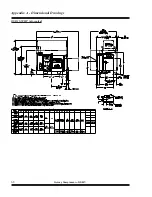

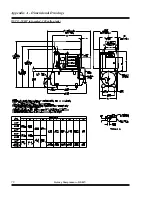

Page 72: ...Appendix A Dimensional Drawings 68 Quincy Compressor QSB T QSB 15 50 HP air cooled...

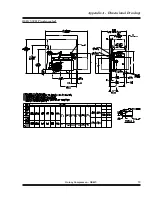

Page 73: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 69 QSB 15 50 HP water cooled...