Do not use grease or other lubricating products between the

pinion and the rack.

5) Bring another rack element closer to the previous one, using a

piece of rack to put the teeth of both sections in phase.

3.4. ZIPPER ASSEMBLY

2) Support the first rack section on the pinion, correctly leveled,

and place the spacer in the upper part of the slot between the rack

and the gate.

4.2. REGULATION OF THE TRANSMITTED TORQUE

ATTENTION: THE ENGINE IS SUPPLIED WITH THE CLUTCH

CALIBRATED TO THE MAXIMUM, SO THE SCREW MUST BE

TURNED TOWARDS THE LEFT UNTIL THE MOST CONVENIENT

CI ON IS SET.

1) Close the leaf manually.

To increase the torque, turn the screw clockwise.

The intervention threshold of the electronic device depends on

the calibration of the mechanical clutch.

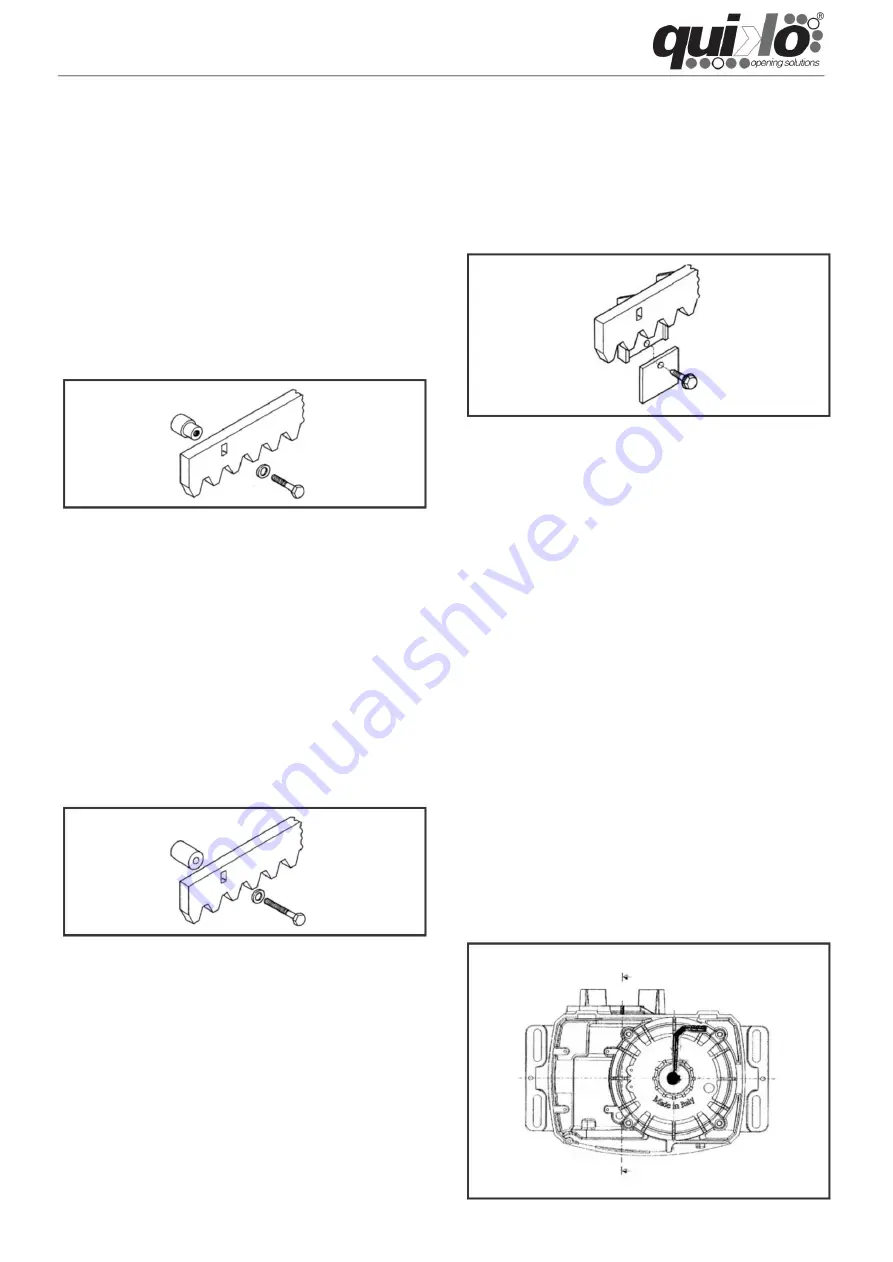

Fig. 9

NB Check that, during the movement of the gate, no element of

the rack comes off the pinion.

4) Move the gate manually, checking that the rack rests on the

pinion, and repeat the operations described in point 3).

3) Move the gate manually, checking that the rack rests on the

pinion, and repeat the operations described in point 2).

Fig. 10

Move the gate by hand and check that it reaches the mechanical

limit stops correctly. The movement should be smooth and without

friction.

4.1. CONNECTING ELECTRONIC EQUIPMENT

6) Move the gate manually and repeat the fixing operations as for

the first element. Continue until the entire gate is covered.

To calibrate the transmitted force regulation system, use the

screw located on the rotation axis of the electric motor (fig. 10).

1) Assemble the three threaded pins on the rack element, placing

them in the upper part of the slot. This way, slot play will allow for

any necessary adjustments as time goes on.

Attention: before carrying out any type of operation on the

electronic equipment (connections, programming or

maintenance), always disconnect the power supply.

2) Support the first section of rack, correctly leveled, on the pinion

and mark the point where the gate should be drilled. Drill with a 4

mm diameter drill bit and place the 6 x 20 mm self-tapping screw

with the respective reinforcement plate.

To reduce the torque, turn it counterclockwise.

3) Support the first rack section on the pinion, correctly leveled,

and weld the threaded pin to the gate. 4) Move the gate manually,

checking that the rack rests on the pinion, and weld the next two

pins.

1) Close the leaf manually.

4) Bring another rack element closer to the previous one, using a

piece of rack to put the teeth of both sections in phase. 5) Move

the gate

manually and repeat the fixing operations as for the first element.

Continue until the entire gate is covered.

3) Mark the drilling point on the gate. Drill with a 6.5 mm diameter

drill bit and thread with an 8 mm tap. Screw in the bolt.

6) Open the gate manually and weld the three threaded pins.

Continue until the gate is completely covered.

Start the engine and manually stop the gate to check the

engagement of the clutch. Remember that, when this operation is

carried out, the electronic anti-crush device interrupts the opening

movement and reverses the closing movement.

5) Bring another rack element closer to the previous one, using a

piece of rack to put the teeth of both sections in phase.

Attention: do not weld the zipper elements to the spacers or to

each other for any reason (only for steel zippers).

Fig. 8

2) Close the leaf manually.

Fig. 7

3.4.2. STEEL RACK TO SCREW (fig. 8)

3.4.3. NYLON ZIPPER TO SCREW (fig. 9)

3.4.1. STEEL ZIPPER FOR WELDING (fig.7)

4. COMMISSIONING

Machine Translated by Google