Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

QVM 9

Series

14

14

14

14

Installation

Installation

Installation

Installation

For safe operation, an ample supply of air must be

provided for proper combustion and ventilation in

accordance with the national fuel gas code, ANSI Z223.1

or CAN/CGA-B149.1 or B149.2(latest editions) or

applicable provisions of the local building codes. An

insufficient supply of air may result in a yellow, luminous

burner flame, carboning or sooting of the finned heat

exchanger, or create a risk of asphyxiation. Do not

obstruct the flow of combustion and ventilation air.

NEVER OPERATE THE HEATER UNLESS IT IS VENTED

TO THE OUTDOORS AND HAS ADEQUATE AIR SUPPLY

TO AVOID RISKS OF IMPROPER OPERATION, FIRE,

EXPLOSION OR ASPHYXIATION.

Lime scale accumulation can reduce the life of the

equipment, reduce efficiency and waste fuel. Boiler failure

due to lime or scale buildup voids the warranty.

■

Piping for heating and hot water

should be cleaned before

connecting to the unit.

■

The boiler needs a large quantity of air for

combustion, the specified vent must be installed. If

not incomplete combustion will occur and prevent

normal operation of the boiler.

■

The boiler should be at least 24

”

away from electric appliances.

The boiler is set up for AC 115V

60Hz.

More than 24"

Only for AC115V, 60Hz

■

Flue made of schedule 40 PVC

or stainless steel.

■

To facilitate the discharge of

exhaust gas, the flue should be

installed with fewest possible

bents and curves. The flue should

have a diameter larger than that of

the flue of the boiler.

■

Do not place flammable items

near the boiler. Never place

combustibles such as vinyl

bags, matches, thinner, etc on

boiler

The flow of combustion air to the boiler must not be

obstructed.

The boiler area must be kept clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

Check the metal tag on the relief valve and compare it to

the heater

’

s rating plate. The pressure rating of the relief

valve must not exceed the working pressure shown on the

rating plate of the heater. In addition, the hourly BTU rated

temperature discharge capacity of the relief valve shall not

be less than the input rating of the heater.

NO VALVE IS

TO BE PLACED BETWEEN THE RELIEF VALVE AND

TANK. DO NOT PLUG THE RELIEF VALVE.

The drain line connected to this valve must not contain a

reducing coupling or other restriction and must terminate

near a suitable drain to prevent water damage during

valve operation. The drain line shall be installed in a

manner to allow complete drainage of both the valve and

line.

DO NOT THREAD, PLUG OR CAP THE END OF THE

DRAIN LINE.

Precautions for Installation

Precautions for Installation

Precautions for Installation

Precautions for Installation

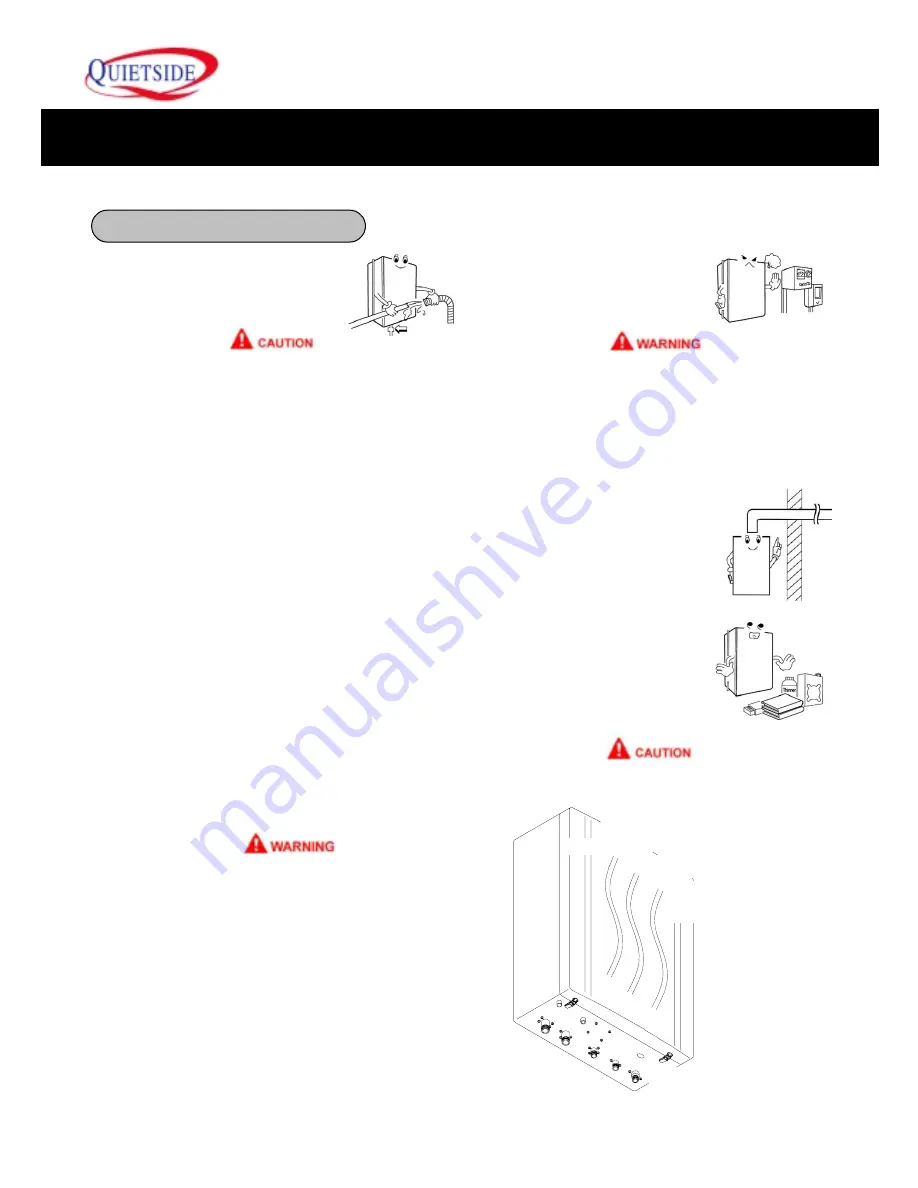

Read first before connection to power supply

Read first before connection to power supply

Read first before connection to power supply

Read first before connection to power supply

Remove Rubber Grommet

Remove Rubber Grommet

Remove Rubber Grommet

Remove Rubber Grommet

to connect line

to connect line

to connect line

to connect line

voltage

voltage

voltage

voltage

Low Voltage

(Thermostat Wire)

Orange

Orange

Blk

Red

Black

White

Green

Low Voltage

(for optional gas alarm)

Gray Wire

(to live voltage)